In the realm of industrial hardware, the significance of proper installation techniques cannot be overstated, particularly when it comes to T Bolt Pipe Clamps. These versatile clamps play a crucial role in securing pipes and fittings across various applications, providing stability and ensuring optimal performance. According to industry expert Johnathan Blake, a mechanical engineer and authority on industrial fastening solutions, "The effectiveness of T Bolt Pipe Clamps hinges not just on their design, but significantly on the precision of their installation."

Understanding the nuances of using T Bolt Pipe Clamps is essential for engineers and technicians alike. Proper usage and installation not only enhance the durability of piping systems but also prevent potential failures that can lead to costly downtimes and safety hazards. In this guide, we will explore the best practices for employing T Bolt Pipe Clamps effectively, ensuring that every installation is executed with the utmost efficiency and precision. From selecting the right size to understanding the torque specifications, mastering these details will empower professionals to achieve optimal results with every project.

T-bolt pipe clamps are essential components used in various industrial applications, particularly in plumbing and HVAC sectors. Designed to secure pipes or hoses in place and accommodate different diameters, these clamps offer a significant advantage over traditional options due to their ability to handle higher pressures and temperatures. For instance, a recent report from the International Journal of Advanced Manufacturing Technology indicates that T-bolt clamps have the potential to withstand pressure ratings up to 150 PSI, making them suitable for more demanding environments than standard hose clamps.

The applications of T-bolt pipe clamps are widespread, ranging from automotive to chemical processing industries. Their robust construction allows for tighter seals and greater resistance to vibrations and movement. In high-performance scenarios, such as racing engines or heavy machinery, T-bolt clamps enable efficient fluid transfer while minimizing the risk of leaks. A study by the American Society of Mechanical Engineers highlights the importance of proper installation and material selection, which can enhance the lifespan of the clamps and the systems they support.

Tips: When using T-bolt clamps, ensure the right size and material are selected for the specific application. It's advisable to inspect the clamps regularly for signs of wear, especially in high-stress environments, to maintain optimal performance. Additionally, always follow manufacturer guidelines for torque specifications during installation, as over-tightening can lead to damage or failure.

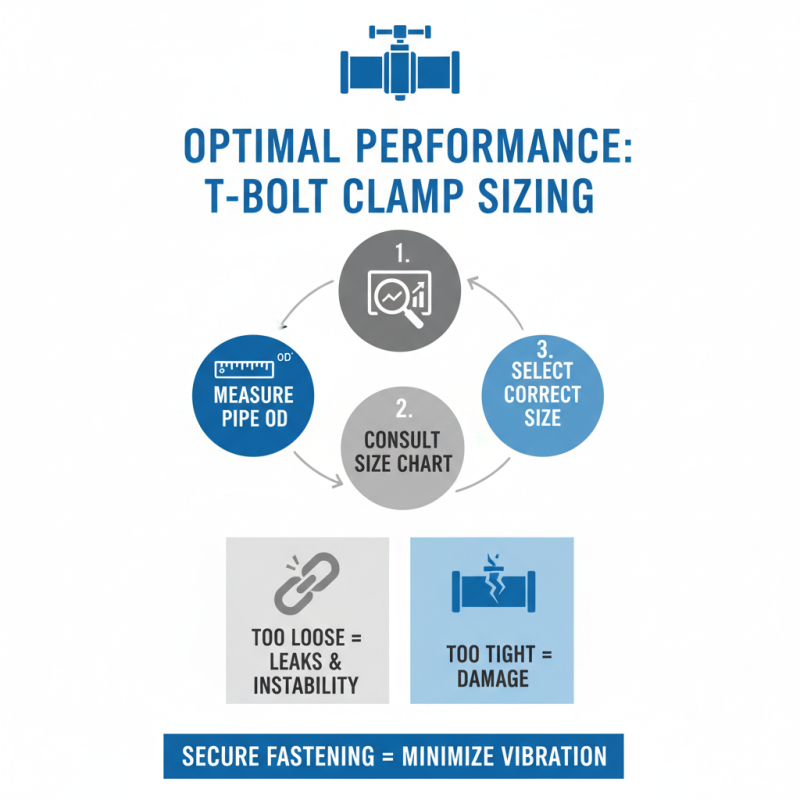

When selecting T bolt pipe clamps, the first consideration should be the appropriate size. Accurate measurement of the pipe's diameter ensures the clamp provides a secure fit. A clamp that is too loose can lead to leaks and instability, while one that is too tight may cause damage to the pipe or the clamp itself. It's advisable to measure the outer diameter of the pipe and consult the manufacturer’s size chart to choose the right clamp size. This will optimize performance by promoting secure fastening, which is crucial for minimizing vibrations and movement.

Material selection is another critical factor in the effectiveness of T bolt pipe clamps. Different materials offer varying degrees of strength, corrosion resistance, and temperature tolerance. Stainless steel is commonly preferred for its durability and resistance to rust, especially in environments exposed to moisture. For applications involving high heat or certain chemicals, assessing compatibility with different materials can prevent premature wear or failure. Consider the specific conditions where the clamps will be used, and choose materials that can withstand those challenges without compromising integrity. This thoughtful approach will enhance the longevity and reliability of the entire piping system.

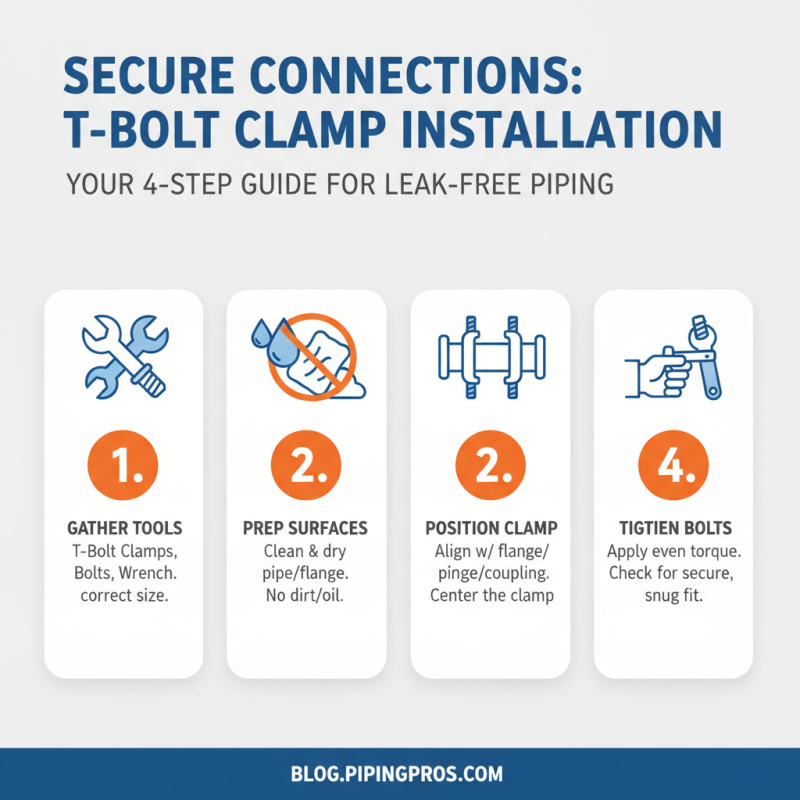

Installing T bolt pipe clamps correctly is crucial for ensuring a secure and leak-free connection in your piping systems. Begin by gathering all necessary tools and materials, including the clamps, bolts, and a wrench. Before installation, ensure the pipe surfaces are clean and dry to facilitate a strong grip. Position the T bolt clamp around the pipe, aligning it with the flange or coupling that it will secure.

Once the clamp is in place, insert the T bolt through the clamp’s designated holes. It is essential to thread the bolt through the clamp’s base securely to avoid slippage during installation. Using a wrench, gradually tighten the nut while ensuring the clamp remains aligned. Avoid over-tightening, as this can damage the pipe or the clamp itself. After achieving a secure fit, double-check the alignment and make any necessary adjustments before moving on to the next connection.

In situations where multiple clamps are needed, repeat the process for each connection to guarantee consistency and performance across the entire system. Regular maintenance checks are recommended to ensure that the T bolt pipe clamps remain tight and secure over time, preventing any potential leaks or failures in the piping system.

When working with T bolt pipe clamps, achieving optimal performance hinges on the proper adjustment and securing techniques. Begin by ensuring that the mating surfaces of the pipes are clean and free from debris, as this will promote a tight seal. Position the clamp around the pipe and make sure the bolt is aligned with the nut before tightening. It is crucial to apply even pressure while securing the clamp to avoid any misalignment that could lead to leaks or failure during operation.

Tips for adjusting T bolt pipe clamps include using a torque wrench to apply the manufacturer-recommended torque settings. This not only ensures a secure fit but also prevents over-tightening, which can damage the clamp or pipe. Furthermore, consider periodically checking the tightness of the clamp during maintenance routines. Environmental factors or vibrations can cause clamps to loosen over time, so adjusting them as needed can prevent potential issues down the road.

Another important technique is to choose the appropriate size of T bolt pipe clamp for your application. Ensuring the correct diameter will help in achieving a secure fit and will prevent the clamp from slipping or causing damage to your piping system. Always consult technical specifications or guidelines specific to your project to maintain the integrity of your installation.

Maintaining T bolt pipe clamps is crucial for achieving longevity and optimal performance in various industrial applications. According to a report by the Industrial Fasteners Institute, regular inspection and maintenance of clamps can extend their service life by up to 50%. This prevents costly downtimes and enhances overall system reliability. Routine checks should focus on ensuring proper tension, inspecting for any signs of wear or corrosion, and ensuring that the clamping area is clean and free of debris. When rust or corrosion is detected, immediate action should be taken to either replace or refurbish the clamps, as prolonged exposure can weaken the clamp and lead to failures.

Moreover, lubrication plays an integral role in boosting the performance and lifespan of T bolt pipe clamps. According to studies conducted by the Society of Manufacturing Engineers, properly lubricated clamps can reduce friction and minimize wear, helping maintain effective sealing. Implementing a regular maintenance schedule that incorporates cleaning and lubrication can significantly enhance the clamps' ability to sustain heavy loads and high pressures. It’s recommended to use a lubricant that is compatible with the materials involved and suitable for the working environment, as incorrect lubricant choices can lead to degraded performance. By adhering to rigorous maintenance practices, organizations can ensure that their T bolt pipe clamps continue to operate efficiently, ultimately leading to safer and more productive operational environments.