In the evolving landscape of plumbing technology, the introduction of No Hub Fittings has revolutionized the way we approach piping systems. These innovative fittings offer a seamless solution for both new constructions and renovations, providing significant advantages over traditional methods. As plumbing professionals seek to improve efficiency, reduce labor costs, and enhance system reliability, No Hub Fittings emerge as a preferred choice. Their unique design not only simplifies installation but also minimizes the potential for leaks, making them an ideal option for various applications.

In this article, we will delve into the numerous benefits of No Hub Fittings and explore how they are unlocking a more efficient, sustainable future for plumbing. By understanding these advantages, industry stakeholders can make informed decisions, harnessing the power of modern plumbing solutions to meet the demands of today’s construction environments.

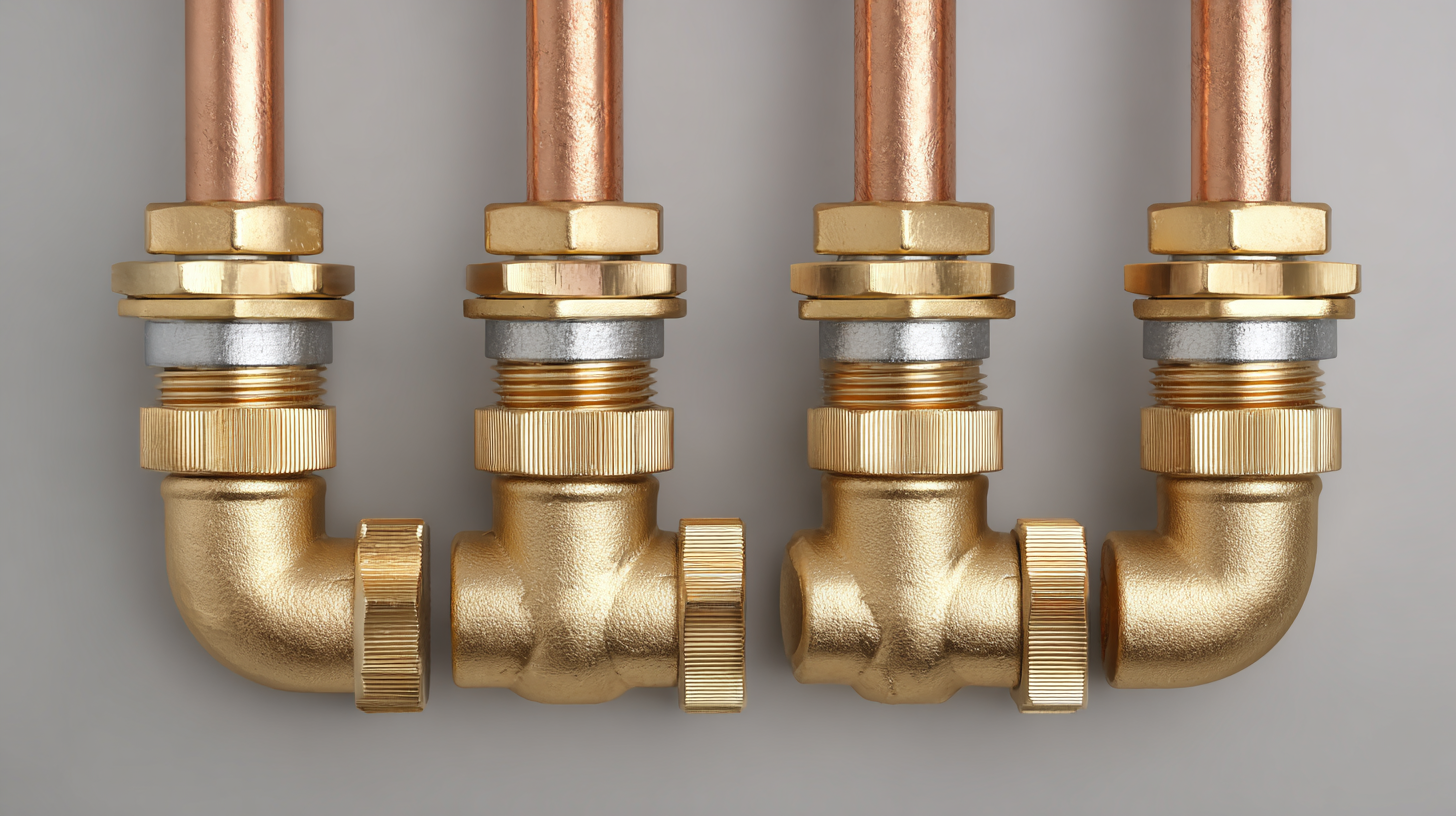

No hub fittings represent a significant advancement in plumbing technology, designed to simplify and enhance the installation and maintenance of drainage systems. These fittings eliminate the need for traditional hub connections by using a rubber coupling to join pipes together. This not only reduces the amount of labor required for installation but also allows for greater flexibility in plumbing layouts, as the fittings can accommodate slight misalignments without compromising the overall integrity of the system.

In addition to their ease of installation, no hub fittings offer exceptional durability and sound attenuation. Made from corrosion-resistant materials, they are less prone to leaks and system failures over time. Their design mitigates noise generated by water flow, making them an ideal choice for residential and commercial settings where quiet operation is favored. Understanding the functionality of no hub fittings is crucial for plumbing professionals and homeowners alike, as they provide innovative solutions for modern plumbing challenges while ensuring efficient performance and longevity.

No hub fittings have emerged as a revolutionary alternative in plumbing systems, offering several key advantages that enhance efficiency and reliability. One of the primary benefits of no hub fittings is their ease of installation. Unlike traditional fittings that require extensive sealing and threading, no hub fittings simply require a rubber coupling and clamps, allowing for quicker assembly and reducing labor costs on installation projects. This streamlined process is particularly advantageous in construction settings where time and efficiency are paramount.

No hub fittings have emerged as a revolutionary alternative in plumbing systems, offering several key advantages that enhance efficiency and reliability. One of the primary benefits of no hub fittings is their ease of installation. Unlike traditional fittings that require extensive sealing and threading, no hub fittings simply require a rubber coupling and clamps, allowing for quicker assembly and reducing labor costs on installation projects. This streamlined process is particularly advantageous in construction settings where time and efficiency are paramount.

Additionally, no hub fittings provide superior versatility and durability. They are designed to accommodate a range of piping materials, including cast iron, PVC, and ABS, making them suitable for various plumbing applications. Their flexible nature also permits slight movements in the piping system, reducing the risk of joint failure due to thermal expansion or ground shifts. Moreover, these fittings boast corrosion resistance, ensuring long-lasting performance even in moist or abrasive environments. With their combination of efficiency, flexibility, and durability, no hub fittings are transforming plumbing systems and paving the way for future innovations in the industry.

When comparing no hub fittings to traditional plumbing options, it's essential to note the significant advantages that no hub systems offer. Traditional plumbing methods often involve various connection types, such as soldering and threading, which can be time-consuming and require specialized skills. On the other hand, no hub fittings streamline installation processes by utilizing a simple rubber coupling and clamp system, which not only reduces labor costs but also minimizes installation time by up to 40%, according to a report by the Plumbing-Heating-Cooling Contractors Association (PHCC).

Additionally, the durability of no hub fittings contributes to their growing popularity. They are designed to withstand higher pressures and are resistant to corrosion, making them a long-lasting alternative. The National Association of Home Builders (NAHB) states that systems incorporating no hub fittings have a failure rate up to 20% lower than traditional threaded pipes, enhancing the reliability of plumbing infrastructures.

Tips for utilizing no hub fittings include ensuring proper alignment during installation to prevent leaks and choosing fittings that meet industry standards for pressure ratings. Furthermore, regular inspection of connections can help maintain the integrity of the plumbing system, extending its lifespan and effectiveness.

When considering the installation of no hub fittings, several factors must be taken into account to ensure optimal performance. One of the primary advantages of these fittings is their ease of installation. Unlike traditional plumbing fittings that require extensive soldering or threading, no hub fittings utilize a compression system that allows for quick and secure assembly. This streamlined installation process not only saves time but also reduces labor costs, making it an attractive option for both professional plumbers and DIY enthusiasts.

Maintenance of no hub fittings is another critical consideration. These fittings are designed to be low-maintenance due to their durable materials and simple construction. They are resistant to corrosion and can withstand high-pressure applications, which minimizes the risk of leaks and the need for frequent repairs. Additionally, inspections and potential maintenance tasks can be carried out easily thanks to the accessible design of no hub fittings. This convenience further enhances their appeal, promoting a long-lasting plumbing solution that can adapt to the evolving needs of modern infrastructure.

The plumbing industry is on the brink of a revolution, driven by the integration of no hub technology and innovative robotic solutions. As the demand for efficient and reliable plumbing systems increases, no hub fittings are emerging as a game-changer. These fittings not only simplify installation and maintenance but also enhance the overall durability and performance of plumbing systems. With fewer joints and connections, the risk of leaks is significantly reduced, making no hub fittings a smart choice for both residential and commercial applications.

Looking ahead, the role of robotics in plumbing is set to expand further, leveraging no hub technologies to streamline processes. Automated systems can assist in the installation of these fittings, reducing labor costs and time while improving accuracy. Additionally, robotic solutions can monitor plumbing infrastructure in real-time, identifying potential issues before they escalate. As plumbing professionals embrace this technological shift, the focus will undoubtedly be on enhancing service efficiency and ensuring customer satisfaction. The confluence of no hub fittings and robotic innovations heralds a new era in plumbing, characterized by smarter, more sustainable practices.