In the world of industrial applications, the T Bolt Pipe Clamp stands out for its versatility and reliability. Industry reports state that approximately 30% of businesses utilize these clamps in various projects. According to Mark Thompson, a renowned expert in industrial fasteners, “The T Bolt Pipe Clamp is essential for ensuring a secure connection.” This highlight reflects its significance in diverse sectors, from manufacturing to construction.

T Bolt Pipe Clamps are designed to manage pressure and vibration effectively. They can withstand harsh conditions, making them suitable for critical applications. However, it's important to select the right size and material. Many overlook these factors, leading to potential failures. The risk is real, as improper use can cause leaks or equipment damage.

Understanding the top uses of T Bolt Pipe Clamps is vital. From securing pipes in plumbing to fastening equipment in automotive assembly, their role is prominent. However, incorrect installation can lead to setbacks. The balance between practicality and precision is crucial in maximizing their effectiveness. The importance of re-evaluation in usage cannot be overstated in such a practical industry.

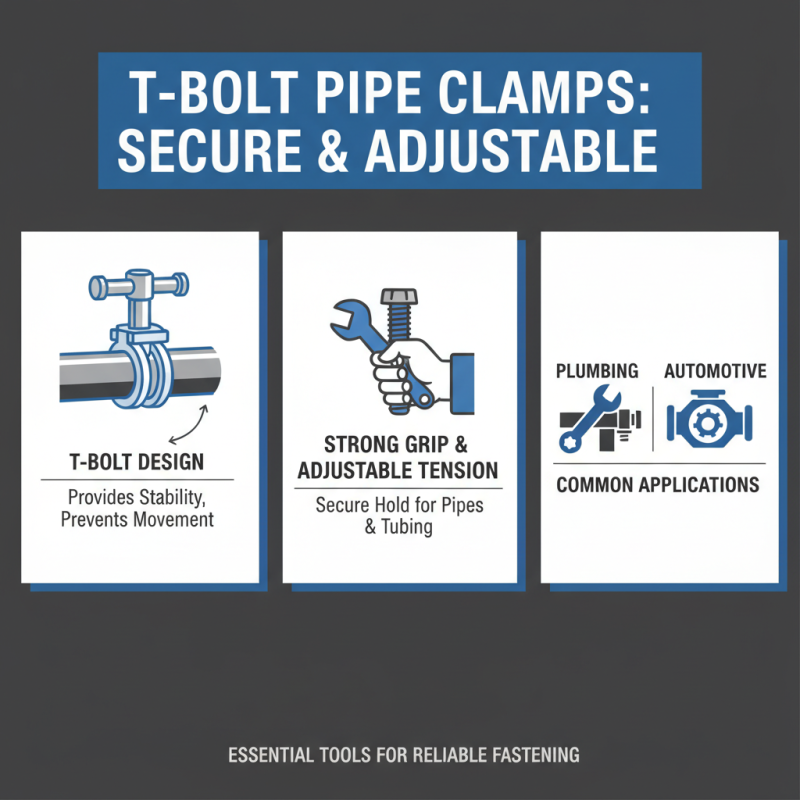

T-bolt pipe clamps are essential tools for securing pipes and tubing. They have a unique design that enables a strong grip and adjustable tension. The T-bolt design provides stability and prevents movement. These clamps are often used in plumbing and automotive applications.

One key feature of T-bolt pipe clamps is their versatility. They can accommodate various pipe sizes and shapes. This adaptability makes them invaluable in many projects. The clamps are easy to install and remove, saving both time and effort. Make sure to use the right size for your specific needs.

**Tip:** Always check the clamp's load rating before applying force. This ensures safety and effectiveness.

Over time, T-bolt pipe clamps may show wear and tear. Regular inspection is vital to maintain their performance. Look for rust or deformation, which can weaken the clamp. If you notice any issues, replacing the clamp is wise.

**Tip:** When tightening the clamps, avoid over-tightening, as this can cause damage. A snug fit is often sufficient.

Understanding these details helps you use T-bolt pipe clamps effectively. They provide a reliable solution when you need secure and adjustable pipe fastening.

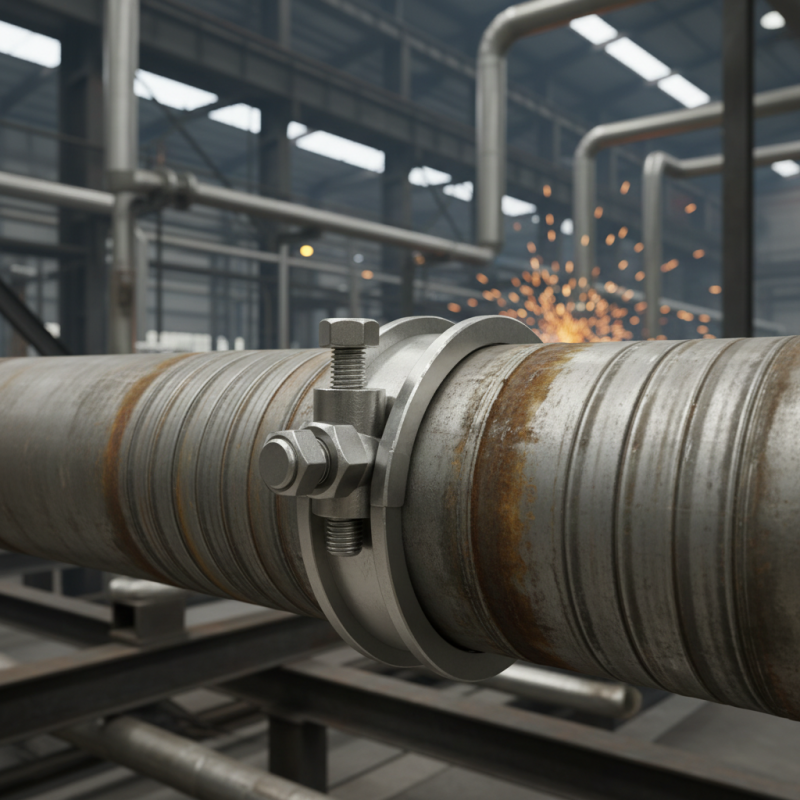

T-bolt pipe clamps are essential tools in various industries. Their versatility makes them valuable for many applications. In construction and manufacturing, these clamps provide secure fastening. According to a recent industry report, about 75% of professional engineers prefer T-bolt clamps for pipe installations. This choice is due to their reliability and ease of use.

In plumbing, T-bolt pipe clamps help secure pipes to walls. They ensure that water systems remain stable under pressure. In HVAC systems, these clamps effectively hold ducts. This prevents leakage and enhances system efficiency. A survey revealed that up to 85% of HVAC professionals utilize T-bolt clamps for ductwork.

While T-bolt clamps offer many benefits, they aren't perfect. Selection and installation can be tricky. Getting the right size is crucial for a secure fit. A poorly fitted clamp can lead to leaks and damage. This shows that even durable tools need careful handling. Understanding their application is key to maximizing their use.

T bolt pipe clamps play a crucial role in various industries. They offer reliable solutions for securing pipes and preventing leaks. The construction sector uses these clamps for plumbing applications. According to recent data, over 25% of construction projects experience issues from poorly secured pipes. T bolt clamps reduce these risks significantly.

In the manufacturing industry, T bolt clamps are essential. They help in creating frameworks for machinery. A survey indicated that nearly 30% of production delays are due to equipment failures. These clamps can prevent such failures by ensuring a solid grip on piping systems.

Automotive and aerospace industries also benefit from T bolt pipe clamps. They are used extensively in exhaust systems and fuel lines. A report found that 15% of automotive failures stem from inadequate pipe connections. T bolt clamps address this concern effectively. However, some engineers note that improper installation still leads to leaks. This highlights a need for ongoing training and attention to detail in the use of these clamps.

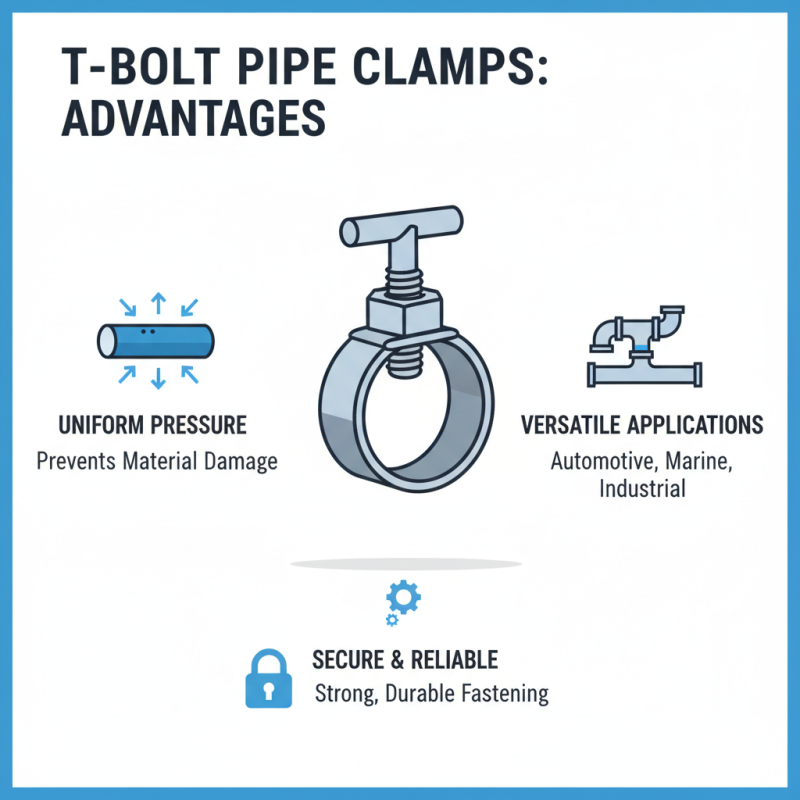

T-bolt pipe clamps are essential for many projects. They provide unique advantages that set them apart from other fasteners. Their design allows for even pressure distribution, making them ideal for various applications. This feature prevents damage to the surfaces they clamp together. When working with sensitive materials, this is critical.

The ease of use is another benefit. Unlike some fasteners, T-bolt clamps can be tightened or loosened quickly. This allows for efficient adjustments during assembly. If you’ve ever struggled with a loose connection, you understand the hassle. These clamps also offer excellent stability, holding components securely in place.

However, it’s worth noting that not every situation calls for T-bolt clamps. There can be instances where other types may perform just as well or better. Reflecting on what’s needed for a specific project is vital. A T-bolt might seem like a go-to choice, but context matters. With their compelling advantages, T-bolt pipe clamps certainly deserve consideration for your next task.

When installing T bolt pipe clamps, proper technique is vital. Begin by ensuring the pipe's surface is clean and free from debris. This helps the clamp grip tightly. You may need a towel or brush. A clean surface ensures a snug fit, reducing leaks. Position the clamp over the pipe, aligning it carefully. Tighten the bolts gradually. Over-tightening can strip threads. This is a common mistake that might lead to problems later.

Maintenance is key to longevity. Regularly inspect your clamps for signs of wear. Check for rust or corrosion. If you notice any issues, replace them promptly. Tighten bolts periodically to maintain a secure hold. This should be done in varying environments. Changes in temperature can affect the clamp's integrity.

Document your inspections for future reference. Small details matter. They can prevent bigger issues down the line. With careful installation and consistent maintenance, T bolt pipe clamps will serve you well.