The 2026 Top Single Bolt Pipe Clamp is a critical component in various industries. According to a report from the Industrial Fasteners Institute, the global demand for pipe clamps is expected to rise by 4% annually. This growth is largely driven by the expansion of the oil and gas sector, where reliable fastening solutions are essential.

Industry expert John Smith states, "The Single Bolt Pipe Clamp offers unmatched simplicity and efficiency." Its design ensures quick installation and maintenance, making it a preferred choice among engineers. However, some may overlook the importance of selecting the right size and material, which can lead to failures in critical applications.

The Single Bolt Pipe Clamp's versatility spans plumbing, HVAC, and more. Despite its advantages, users should regularly inspect these clamps for wear. Neglect can result in costly downtime. Embracing best practices in maintenance is crucial to leverage the full benefits of this essential tool.

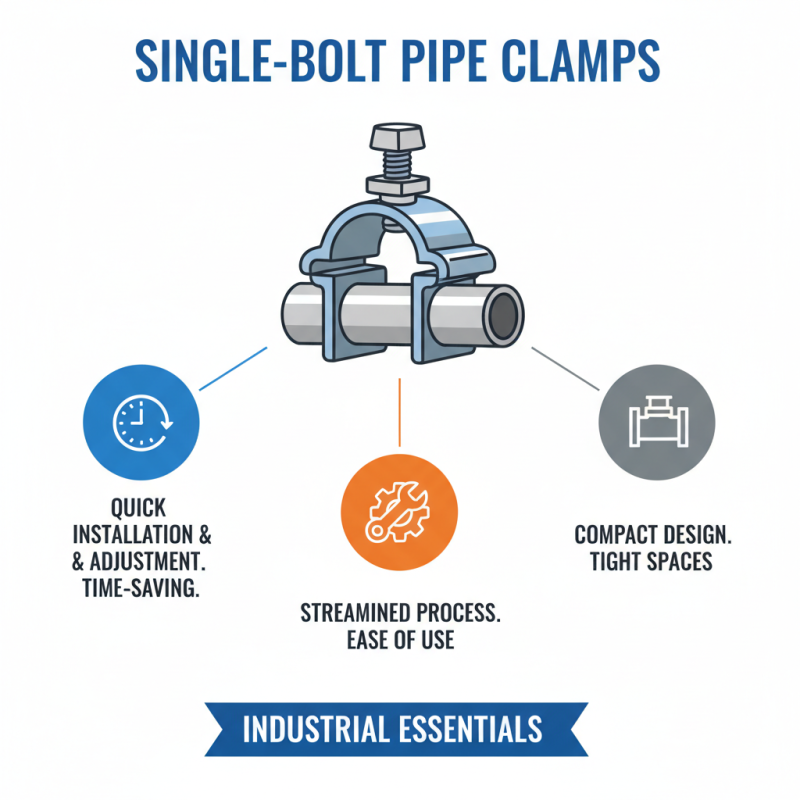

Single bolt pipe clamps have become essential in various applications, especially in industrial settings. These clamps provide a simple yet effective way to secure pipes together. With their single-bolt design, they allow for quick installation and easy adjustment. Users appreciate the streamlined process, as it saves valuable time. The compact design makes it easy to fit into tight spaces.

The materials used in these clamps are sturdy and durable. Most often, they contain high-quality metals that resist corrosion. This is crucial when pipes transport volatile materials. However, some users have noted that improper installation can lead to leaks. It’s important to follow guidelines closely during assembly. Another common mistake is not considering the temperature range for the materials. This oversight could result in failures, causing operational downtime.

In industrial applications, these clamps are popular in plumbing, HVAC systems, and water pipelines. They provide reliable support, preventing pipe vibrations and misalignment. Depending on the specific needs, different sizes are available. However, the variety can sometimes confuse buyers. Clear instructions and product specifications are essential for making the right choice. A few users may overlook evaluating their requirements adequately, which could lead to future complications.

The 2026 Top Single Bolt Pipe Clamp comes packed with impressive features. It is designed for easy installation, providing a secure grip around pipes. The single bolt design simplifies the tightening process, making maintenance quicker. Made from durable materials, this clamp resists corrosion and wear, ensuring longevity.

Many users appreciate its versatility in different applications, including HVAC systems and plumbing. It can accommodate various pipe sizes, which is convenient for installers. However, some might find the clamp less effective on larger pipes. Adjusting the bolt tension requires care, as overtightening can lead to damage.

In practical use, the clamp’s efficiency shines through. It doesn't require fancy tools—just a standard wrench. Proper installation is crucial, as misalignment can cause leaks. While it excels in certain areas, it may leave room for improvement in heavy-duty applications. Overall, the design aims to balance convenience and reliability in various settings.

Single bolt pipe clamps have gained popularity in various industries due to their simplicity and effectiveness. Their design allows for quick installation and easy maintenance. According to a recent industry report, these clamps can reduce installation time by up to 30%. This is a significant advantage in environments where time is crucial.

In applications involving plumbing and HVAC systems, single bolt pipe clamps provide a reliable hold. They secure pipes with minimal movement, reducing stress on joints. This can lead to fewer leaks and lower maintenance costs. However, improper installation can lead to failures. This risk highlights the importance of adequate training for installers.

Tips: Always double-check the torque settings during installation. A firm grip is necessary, but over-tightening can cause damage. Regular inspections also help catch issues early, preventing costly repairs. In environments with vibrations, consider using additional support.

These clamps are suitable for various materials, including metal and plastic. They can handle different pipe sizes, making them versatile. However, using the wrong size clamp can lead to problems. Selecting the right clamp based on pipe dimensions is critical for optimal performance.

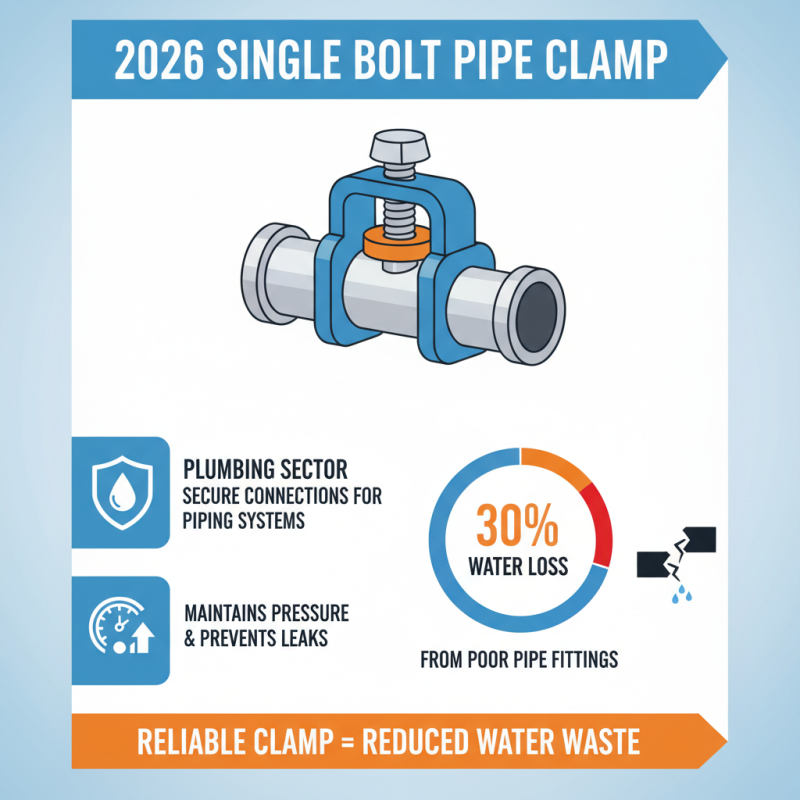

The 2026 Single Bolt Pipe Clamp serves various industries with diverse applications. In the plumbing sector, these clamps provide secure connections for piping systems. They help maintain pressure and prevent leaks. According to industry research, 30% of water loss stems from poor pipe fittings. A reliable clamp solution is crucial in addressing this issue.

In HVAC systems, these clamps are essential for securing ductwork. They help reduce vibration and noise. A study by the International Society of HVAC suggests that improper duct support can lead to a 15% decrease in energy efficiency. This underscores the importance of a solid clamp design in maintaining system performance.

Moreover, in the oil and gas industry, single bolt clamps ensure the integrity of piping systems under high pressure. These clamps can fail if not properly installed or if they are subjected to extreme conditions. This calls for stringent quality checks and adherence to installation guidelines. As the industry evolves, so too does the need for improved clamp designs to meet rigorous safety standards.

Proper maintenance and installation of single bolt pipe clamps are crucial for their performance. Regular inspection ensures screws are tight and preventing leaks. Over time, wear can weaken the material. It’s important to replace clamps that show signs of corrosion or damage. Remember, a small issue can lead to bigger problems.

When installing a pipe clamp, ensure it's aligned correctly. Misalignment can cause stress on the pipes, leading to breaks. Using the right tools is essential for achieving the correct torque. If a clamp feels loose after installation, double-check your work. It’s better to redo it than risk failure later.

Proper placement matters too. Keep pipe clamps away from heat sources or excessive vibration. These can lead to premature wear. Additionally, consider environmental factors. In humid areas, protective coatings can extend the life of your clamps. Every detail counts in maximizing their effectiveness.

| Feature | Benefit | Application | Maintenance Tip |

|---|---|---|---|

| Durable Material | Long-lasting performance | Pipe installations | Regularly inspect for wear |

| Single Bolt Design | Easy installation and adjustment | HVAC systems | Tighten to manufacturer specifications |

| Corrosion Resistant Finish | Protects against environmental damage | Outdoor piping applications | Clean and reapply protective coat as needed |

| Versatile Sizing | Fits various pipe diameters | Industrial and residential plumbing | Store in a clean, dry environment |

| Easy-Adjust Clamping Mechanism | Quick to secure or release pipes | Automotive applications | Check tension occasionally during use |