When it comes to construction and plumbing, the right support system is essential. One of the key components is the Clevis Hanger. Clevis hangers are versatile devices that secure piping systems to walls or ceilings. They offer strength and stability, but not all are created equal.

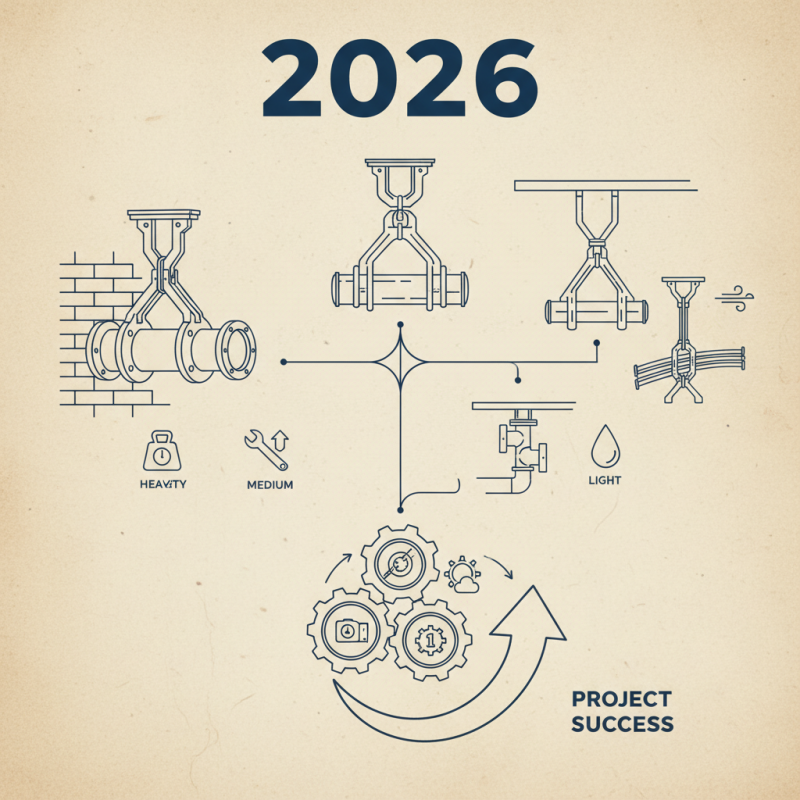

Choosing the right Clevis Hanger can be daunting. There are various types and sizes, each with its specific applications. Some are ideal for heavy-duty piping, while others work best with lighter systems. The decision often feels overwhelming. Mistakes can lead to structural weaknesses or costly repairs.

Take the time to evaluate your project. Consider factors such as pipe size, material, and environment. Each choice carries weight. Understanding the nuances of different Clevis Hanger types can make a significant difference. Don't rush; reflect on your needs. This is an opportunity to enhance your project’s success.

Clevis hangers are essential in construction. They provide support for various plumbing and HVAC systems. The common types include standard clevis hangers, adjustable hangers, and roller hangers. Each serves a unique purpose, adapting to different installation needs.

Standard clevis hangers are versatile. They can hold pipes of various sizes securely. However, they might not fit all setups perfectly. Adjustable hangers offer flexibility. They allow for easy modifications during installation. Yet, adjustments can complicate the process at times.

Roller hangers are designed for moving pipes. They help accommodate thermal expansion. This is crucial in environments with temperature fluctuations. But, they require careful installation. Misalignment can lead to issues down the line. Consider these factors when selecting the right type for your project.

When choosing clevis hangers, material considerations play a vital role. Different projects require different materials to ensure durability and efficacy. For example, stainless steel offers excellent corrosion resistance. It is perfect for outdoor applications or areas with high humidity. On the other hand, carbon steel is often used for indoor structures. While it is cost-effective, it does require protective coatings to prevent rust.

Another popular option is plastic clevis hangers. They are lightweight and resistant to certain chemicals. However, their strength may not match metal options. Consider the specific environment before making a choice. The wrong material could lead to failures under stress.

Reflecting on your needs can guide your decisions. Are you prioritizing cost, or is longevity more important? Each choice has its trade-offs. Take time to evaluate the materials based on your specific requirements. The right clevis hanger can enhance project stability, while the wrong one might lead to complications later.

When selecting clevis hangers, load capacity is crucial. Each type offers different strengths. Understanding these can prevent failures. Do you know how much weight your system bears? It’s vital to assess your needs accurately. Standard hangers can handle various loads, but extreme conditions may require specialized options.

Performance factors also play an important role. Temperature fluctuations can impact materials. Some hangers perform better in high heat. Others may corrode in moist environments. Knowing your environment helps in choosing the right type. Some users overlook this detail, leading to premature failures.

Installation quality affects hanger efficiency too. Improper alignment can cause stress points. Check for proper fitting. Regular inspections can mitigate issues. However, many users forget to do this. Ignoring maintenance can lead to costly repairs. What does your inspection routine look like? It’s worth considering what could go wrong.

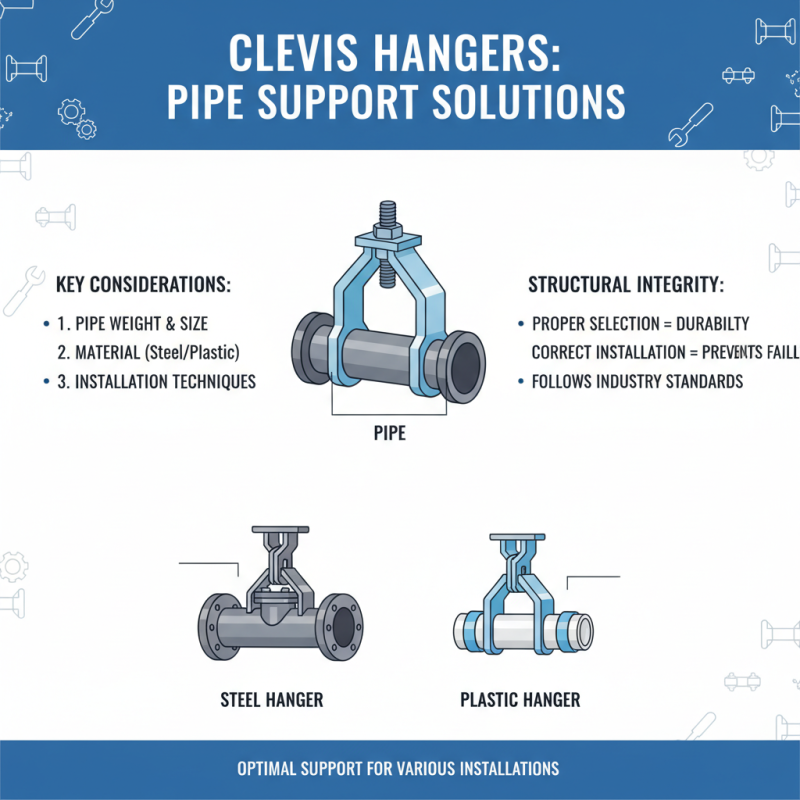

Clevis hangers are essential for supporting pipes in various installations. Understanding installation techniques for different designs is key to achieving structural integrity. When selecting a clevis hanger, consider the weight and size of the pipe. The choice of material also plays a role. Steel and plastic hangers must be installed correctly to prevent future failures.

Proper installation involves several steps. Begin with marking accurate locations for the hangers. Ensure they are spaced according to the pipe’s diameter. Tightening each hanger securely is crucial. A looser hanger can lead to sagging or misalignment. Pay attention to the level of the pipe after installation. Adjustments may be needed, especially in uneven surfaces.

Always verify the alignment after every step. Even small misalignments can cause major issues later. Testing the setup before finalizing is wise. It’s a learning process; mistakes can teach valuable lessons. Observing how each hanger reacts under weight can provide insights into best practices. Being meticulous will ensure a robust installation, preventing headaches down the road.

When choosing clevis hangers, safety standards are crucial. These components secure pipes and ducts in various applications. The American National Standards Institute (ANSI) outlines guidelines for using hangers safely. Proper installation is key to preventing accidents. A small miscalculation can lead to significant structural issues.

Data from the National Fire Protection Association (NFPA) shows that improper support can contribute to nearly 30% of pipe failure incidents. The same report emphasizes that regular inspections are essential. They help ensure compliance with safety regulations. Unexpected failures not only damage infrastructure but may also pose serious safety hazards.

Moreover, ensuring that hangers meet industry specifications is vital. Different materials can react differently under pressure or extreme temperatures. A study from the International Society for Structural Engineers highlights that using low-quality materials may compromise safety. While many assume all hangers are the same, variations exist that can significantly affect their performance.