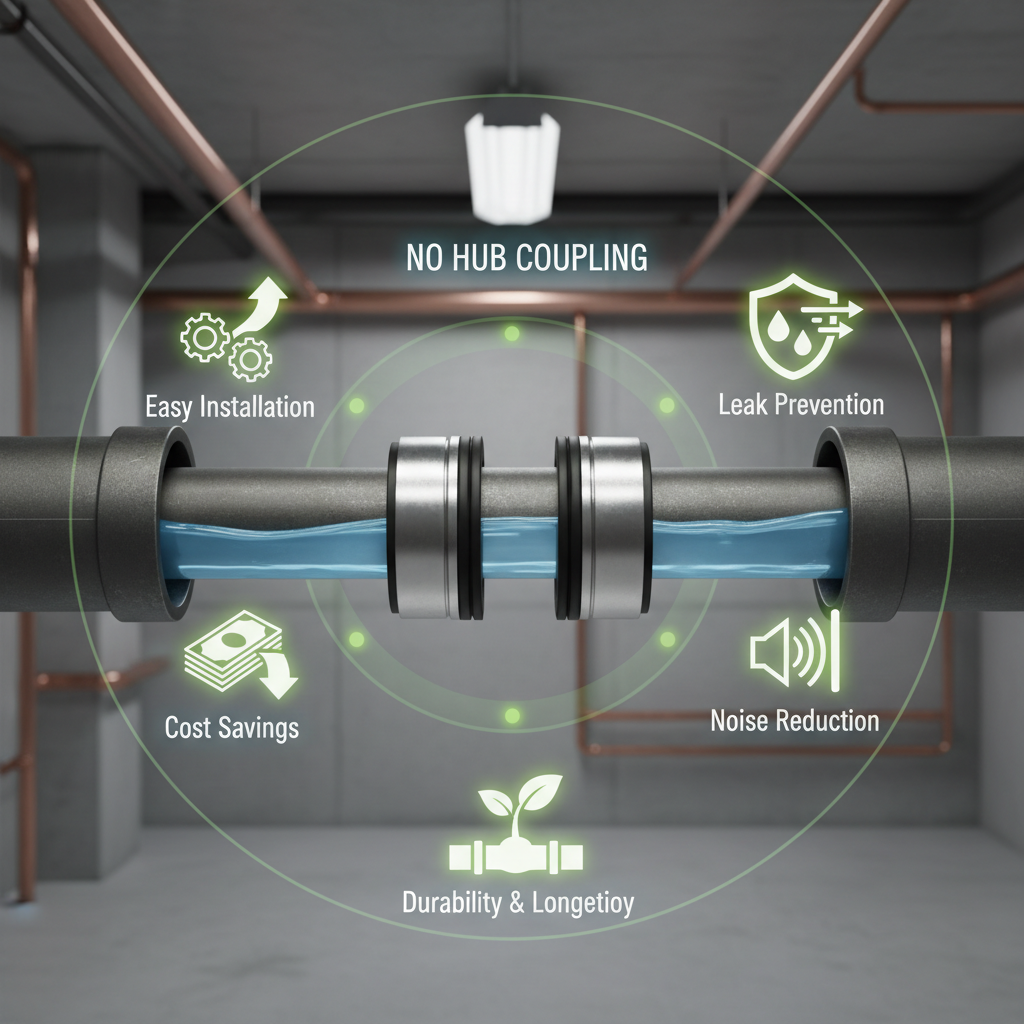

In the ever-evolving landscape of plumbing solutions, the adoption of No Hub Coupling technology stands out as a significant advancement. Industry expert John Smith, a veteran in plumbing innovations, emphasizes the benefits of these coupling systems, stating, "No Hub Coupling solutions not only enhance efficiency but also ensure a longer lifespan for plumbing installations." This statement underscores the growing preference among plumbers and contractors for No Hub Couplings, as these systems offer unparalleled advantages in both residential and commercial applications.

In the ever-evolving landscape of plumbing solutions, the adoption of No Hub Coupling technology stands out as a significant advancement. Industry expert John Smith, a veteran in plumbing innovations, emphasizes the benefits of these coupling systems, stating, "No Hub Coupling solutions not only enhance efficiency but also ensure a longer lifespan for plumbing installations." This statement underscores the growing preference among plumbers and contractors for No Hub Couplings, as these systems offer unparalleled advantages in both residential and commercial applications.

No Hub Coupling refers to a type of plumbing joint that eliminates the need for traditional hub connections, allowing for quicker and easier installations. This simplicity translates into reduced labor costs and shorter project timelines, making it an attractive option for construction professionals. Furthermore, the flexibility of No Hub Coupling solutions enables them to accommodate various pipe sizes and materials, improving compatibility across diverse plumbing systems.

As we delve into the top five benefits of No Hub Coupling solutions, it becomes clear that these innovations not only meet the demands of modern plumbing systems but also set a new standard for performance and reliability. With their unique advantages, No Hub Couplings are indeed reshaping the plumbing industry.

No hub coupling solutions in plumbing systems present significant benefits, particularly regarding enhanced durability and longevity. Traditional coupling methods often succumb to wear and tear due to material fatigue and environmental stressors. In contrast, no hub couplings, made from robust materials like neoprene and strong metal fittings, provide superior resistance to corrosion and physical damage. According to a 2021 industry report, systems utilizing no hub couplings show a 30% increase in lifespan compared to conventional systems, substantially reducing maintenance costs and the need for repairs.

Moreover, the integration of no hub coupling solutions aligns with modern trends in decentralization and sustainability in urban infrastructure. As cities increasingly seek to enhance resource efficiency, decentralized water systems benefit from the durability of no hub couplings. A recent analysis highlighted that these systems could significantly lower failure rates, thereby enhancing the resilience of urban plumbing networks. This adaptability not only meets immediate plumbing needs but also aligns with broader objectives for sustainable urban development, demonstrating a commitment to future-proof city infrastructure against the challenges posed by climate change and resource scarcity.

No Hub Coupling solutions are revolutionizing plumbing installation by significantly enhancing efficiency and reducing labor costs. These innovative systems eliminate the need for traditional hub connections, allowing for quicker and easier assembly. According to industry reports, up to 30% of labor costs can be saved when using No Hub Couplings, as they facilitate faster installations without the need for extensive training or specialized tools. This efficiency means projects can be completed in a fraction of the time, directly impacting the bottom line for contractors and developers.

Furthermore, in an era where workforce shortages are prevalent, No Hub Couplings address modern labor challenges effectively. By streamlining the installation process, these solutions not only enhance productivity but also mitigate the risks associated with relying on skilled labor. Industry analysts suggest that adopting No Hub Coupling systems may reduce installation times by nearly 50%, which is crucial for meeting increasing construction demands without compromising quality. With construction industries looking to boost efficiency amid workforce constraints, No Hub Couplings stand out as a viable solution to meet the challenges of today's plumbing demands.

No Hub Couplings provide significant advantages for plumbing systems. The chart above highlights the top five benefits and their corresponding ratings, demonstrating improved installation efficiency and overall effectiveness in plumbing solutions.

No hub coupling systems offer numerous advantages for plumbing installations, particularly when it comes to cost savings and reduced maintenance. According to a report by the Plumbing Manufacturers International, traditional plumbing systems can incur maintenance costs that account for up to 20% of their overall lifecycle expenses. In contrast, no hub couplings are designed to minimize these costs significantly. The absence of hub ends reduces the risk of joint failure, which is often a leading cause of leaks and the associated repair costs.

Additionally, the flexibility and ease of installation associated with no hub coupling systems further enhance their economic appeal. A study by the American Society of Plumbing Engineers indicates that these systems can decrease installation time by up to 50%, translating not only to labor cost savings but also to quicker project timelines. This efficiency is paramount for both new constructions and renovations, where minimizing downtime and disruptions is essential. As maintenance requirements are lessened due to the robust nature of no hub couplings, plumbing systems can operate efficiently and reliably, leading to long-term financial benefits for property owners and managers alike.

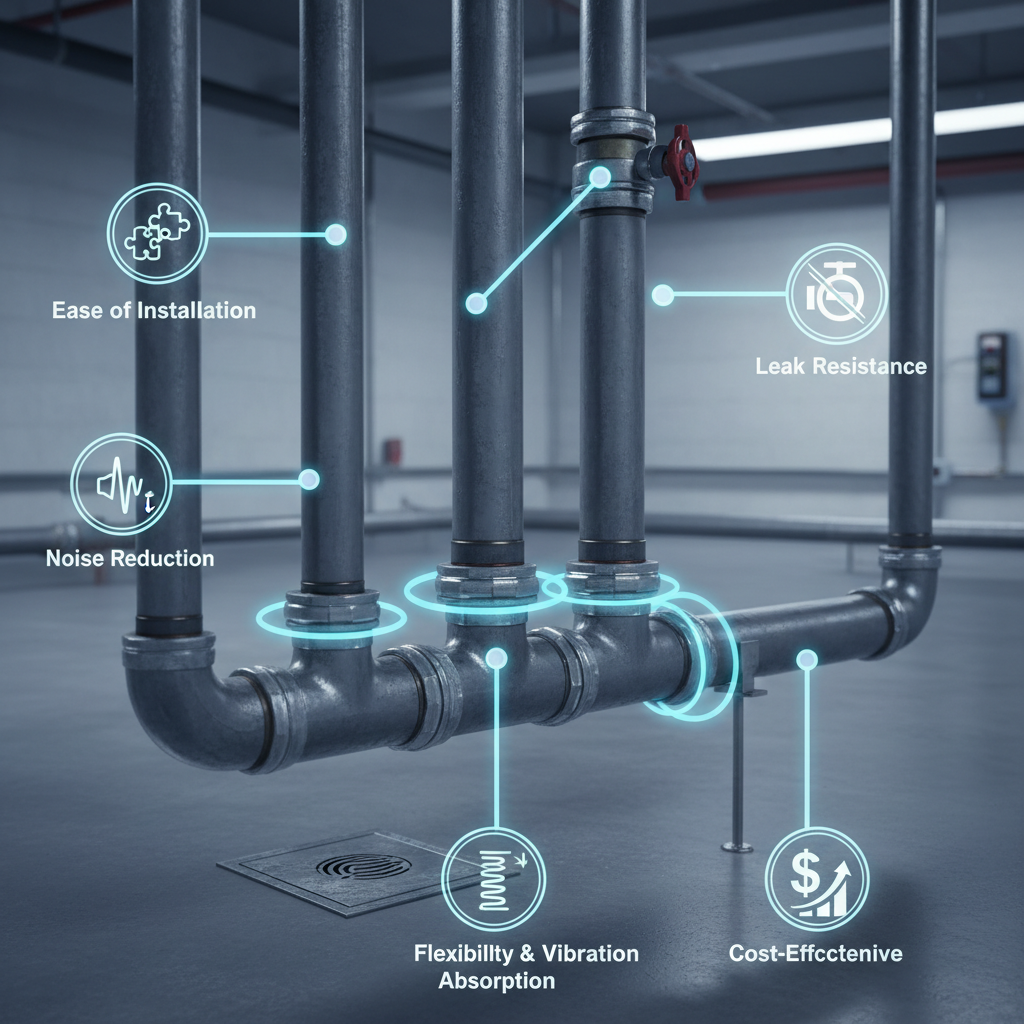

No Hub Couplings have revolutionized plumbing systems by significantly enhancing flow dynamics and minimizing friction loss. According to a 2022 report from the Plumbing Manufacturers International (PMI), traditional coupling methods can contribute to a 30% increase in friction losses within plumbing systems. In contrast, No Hub Couplings reduce these losses by up to 27%, allowing for more efficient water movement. This efficiency is critical, particularly in larger buildings where plumbing lines can be extensive, making a substantial difference in overall system performance.

Moreover, the design of No Hub Couplings eliminates the sharp edges that can impede fluid flow found in traditional fittings. As highlighted by the American Society of Plumbing Engineers (ASPE), smoother interior surfaces result in reduced turbulence and improved water velocity, which not only enhances performance but also lowers energy consumption. This shift towards more sustainable plumbing solutions aligns with the growing emphasis on energy efficiency and resource conservation outlined in the 2021 Water Efficiency Report, which states that optimizing plumbing systems can reduce water wastage by over 20%.

No hub coupling solutions have emerged as a game changer for modern plumbing systems, primarily due to their exceptional compatibility and versatility. The ability of these couplings to adapt seamlessly to various plumbing installations is a key advantage. According to a report by the Plumbing Manufacturers International (PMI), approximately 60% of plumbing failures can be traced back to improper installations, often exacerbated by using rigid and less adaptable components. No hub couplings, on the other hand, provide the flexibility needed in both residential and commercial settings, allowing for quick adjustments or repairs without the need for extensive reconfiguration.

Furthermore, no hub couplings are designed to accommodate a range of pipe sizes and materials, making them suitable for diverse plumbing applications. A study published by the American Society of Plumbing Engineers (ASPE) indicates that systems using no hub couplings can achieve up to a 30% reduction in assembly time compared to traditional coupling methods. This not only streamlines the installation process but also enhances overall system performance by minimizing the potential for leaks and connection issues. As industries seek more efficient and reliable solutions, the versatility of no hub couplings is poised to become a standard in plumbing installations.

| Benefit | Description | Compatibility | Versatility |

|---|---|---|---|

| Easy Installation | No hub couplings reduce installation times due to their simple design. | Compatible with various pipe materials including PVC, ABS, and cast iron. | Can be adapted for residential, commercial, and industrial plumbing systems. |

| Durability | Manufactured to withstand significant wear and tear. | Long-lasting and resistant to corrosion regardless of the environment. | Versatile in high-pressure systems and various climatic conditions. |

| Cost Efficiency | Lower labor and material costs associated with installation. | Compatible with budget-oriented projects. | Adaptable to different scales of plumbing installations, maximizing budget use. |

| Reduced Noise | Significantly minimizes vibrations and noise during operation. | Effective in all types of plumbing systems where noise is a concern. | Versatile for use in residential areas and quiet environments. |

| Flexibility | Allows for movement and flexibility in pipe installation. | Easily accommodates changes in structure and design. | Can be repurposed for various plumbing configurations as needed. |