PVC clamps are essential tools used in various applications. They provide a reliable method to secure PVC pipes and other tubing. The versatility of PVC clamps allows for use in construction, plumbing, and electrical projects.

These clamps come in different sizes and shapes. They can accommodate various pipe diameters. Additionally, PVC clamps can withstand harsh environments, making them suitable for outdoor use. However, it is crucial to choose the right clamp size for optimal performance. An ill-fitting clamp might lead to leaks or pipe damage.

While PVC clamps are generally dependable, users should inspect them regularly. Over time, wear and tear can occur. This can impact their effectiveness. Reflecting on the proper use and maintenance of PVC clamps is vital. It ensures their longevity and reliability in projects.

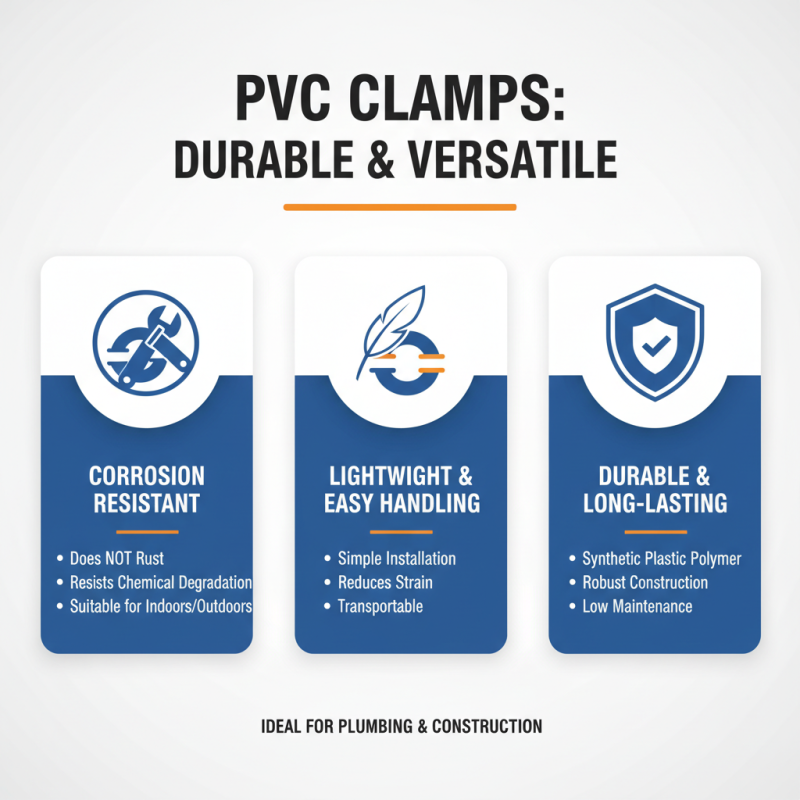

PVC, or polyvinyl chloride, is a synthetic plastic polymer widely used in various applications, including construction and plumbing. It is preferred for clamps due to its durability and resistance to corrosion. PVC does not rust or degrade like metal. This makes it suitable for both indoor and outdoor use. Clamps made from PVC are lightweight, making them easy to handle during installations or repairs.

When choosing PVC clamps, consider their size and strength. Too large, and they may not hold firmly; too small, and they might break under pressure. Always check the specifications to ensure you select the right clamp for your needs.

**Tips:** Ensure that the clamp fits snugly and securely around the pipe or material. If it feels loose, it might fail. Sometimes, we overlook small details like choosing the right size. This oversight can lead to leaks or failures down the line.

Another aspect to consider is temperature resistance. PVC can become brittle in extreme temperatures. Be cautious in applications where high heat might be a factor. Testing the environment before installation can help avoid this issue.

PVC clamps are essential in various industries, particularly in plumbing and construction. Their versatility stems from the different materials and designs available. Commonly, PVC clamps are made from PVC, stainless steel, and aluminum. Each material offers unique benefits. For instance, PVC is lightweight and resistant to corrosion, making it suitable for humid environments. Meanwhile, stainless steel provides superior strength and durability for demanding applications.

Design variations of PVC clamps include standard, adjustable, and heavy-duty types. Standard clamps work well for general purposes, while adjustable models offer flexibility for various pipe sizes. Heavy-duty clamps, on the other hand, support larger pipes under high pressure. According to a report by the American Society of Plumbing Engineers, proper clamping methods can reduce leak rates by over 30%. Designers face challenges in balancing material strength and cost. This balance is crucial for optimal performance.

Innovative designs are emerging, targeting specific needs. For instance, some clamps now feature anti-slip surfaces or integrated vibration dampeners. These features enhance stability under dynamic conditions. However, the industry must continuously adapt to new materials and methods. There is a constant push for sustainability, which sometimes complicates material sourcing. Exploring these design variations will lead to improvements, yet the need for testing and validation remains evident.

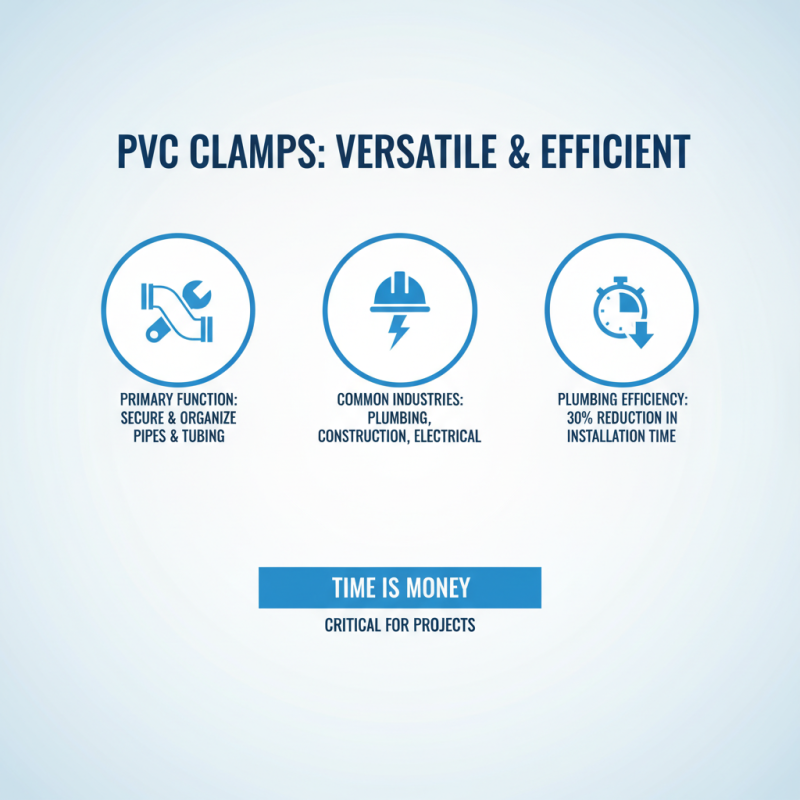

PVC clamps are versatile components used in various industries. Their primary function is to secure and organize pipes and tubing. They are commonly found in plumbing, construction, and electrical installations. In the plumbing industry alone, it is estimated that PVC clamps can reduce installation time by 30%. This efficiency is critical for projects where time is money.

In the construction sector, PVC clamps play a vital role in supporting electrical and plumbing systems. They help maintain order and safety. For instance, when used in cable management, they prevent tangling and potential hazards. Reportedly, employing clamps can improve installation accuracy by up to 25%. This leads to fewer reworks, which is essential for project budgets.

**Tip:** Ensure you choose the right size of clamp. A snug fit avoids slippage but allows for material expansion.

PVC clamps are also prevalent in the automotive sector. They secure hoses and cables, maintaining optimal performance. When not appropriately used, it can lead to mechanical failures. Understanding the load and stress on each clamp is vital. Always check specifications before installation.

**Tip:** Regularly inspect clamps for wear and tear to avoid unexpected breakdowns.

Using PVC clamps effectively can greatly enhance operational efficiency across all industries.

PVC clamps are essential in various applications. Proper installation and maintenance can prevent failures. Most industrial reports indicate that nearly 30% of maintenance issues arise from improper fitting of PVC clamps. This statistic highlights the need for diligence during installation.

When installing PVC clamps, ensure they are tight but not overly so. Over-tightening can damage the pipes, causing leaks or breakage. It's advisable to use a torque wrench to achieve the right tightness. Regular inspection is crucial. Aim for monthly checks to identify signs of wear, corrosion, or cracks.

Interestingly, many users overlook the importance of cleaning the clamp area. Dirt and debris can lead to increased friction. This friction can wear out the clamp faster than expected. Keeping the area clean aids in prolonging the lifespan of the clamps. Reports suggest that a little maintenance can extend their life by as much as 50%. Ignoring these steps can lead to costly repairs and downtime.

The use of PVC clamps has surged in various industries. These clamps are essential in plumbing, construction, and electrical applications. They provide secure connections and support for pipes and cables. As industries evolve, the demand for reliable and cost-effective solutions rises. Current market trends indicate a shift towards durable and environmentally friendly materials. This could enhance the longevity and applicability of PVC clamps.

However, not all PVC products are created equal. Quality control issues sometimes arise, leading to weaker clamps in specific batches. This problem can compromise integrity in critical applications. Moreover, some users question the effectiveness of PVC in extreme conditions. It’s crucial to understand that while PVC clamps are versatile, they may not be suited for every environment. There’s an ongoing need for research and development to address these limitations, ensuring that future products meet higher standards.

Looking ahead, the outlook for PVC clamps appears optimistic. Innovations are likely to emerge, focusing on sustainability and enhanced performance. Manufacturers are responding to market demands for safer and more resilient materials. As new designs roll out, they promise better efficiency and user satisfaction. The market should remain vigilant and adaptive to these changes. This will help overcome existing challenges and fully harness the potential of PVC clamps in future applications.