A Pipe Strap Clamp is a practical tool in various piping applications. It is essential for securing pipes to walls or ceilings. This clamp keeps pipes stable and reduces movement. Made from durable materials, it can withstand pressure and weight.

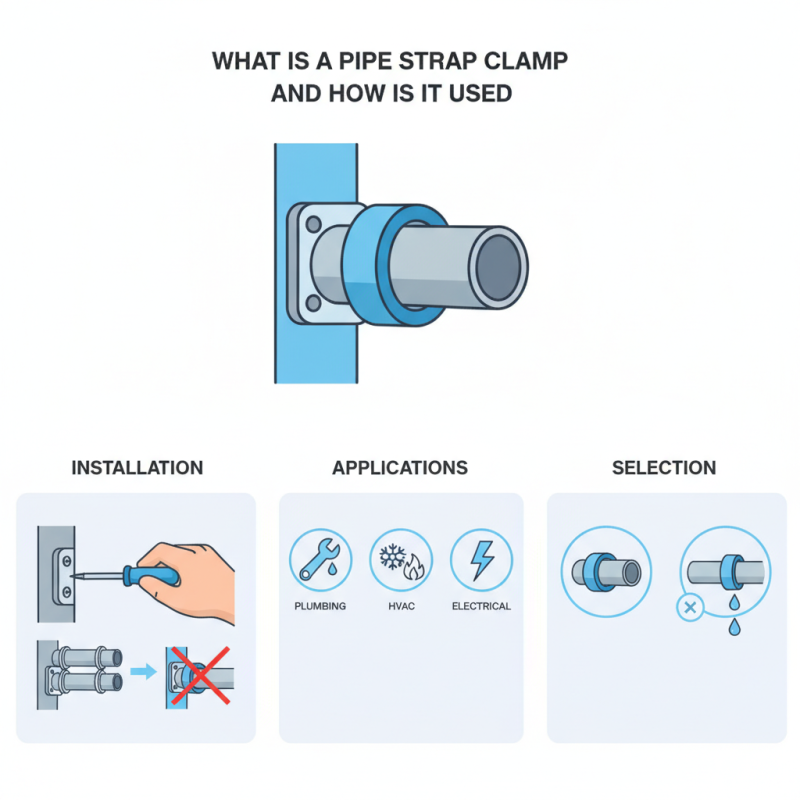

Understanding how to use a Pipe Strap Clamp can improve your projects. The installation is straightforward, often requiring just a few screws. This simplicity often leads to overlooked mistakes. Some users may struggle with alignment, affecting overall integrity.

Pipe Strap Clamps can be used in plumbing, HVAC, and electrical work. Their versatility makes them a go-to for many professionals. However, awareness about selecting the right size is crucial. A poorly fitted clamp can lead to leaks or damage. Consider these aspects for effective usage and better results.

A pipe strap clamp is a simple yet effective device. It primarily secures pipes to structures or surfaces. These clamps are designed to withstand various environmental conditions. They come in different sizes to accommodate various pipe diameters. Made of durable materials, they resist corrosion and wear.

Installation of a pipe strap clamp is straightforward. Typically, one can attach the clamp by drilling screws into the surface. However, the placement needs to be precise. An improper fit can lead to movement or damage. This error may create leaks or structural issues over time. It’s essential to check the alignment after installation.

Many users overlook the importance of regular maintenance. Inspecting the clamps for wear helps ensure longevity. Rust or cracks can indicate a problem. Addressing these issues promptly saves time and money in the long run. Pipe strap clamps play a crucial role in plumbing and construction. Their effectiveness hinges on correct usage and consistent care.

Pipe strap clamps are vital in various industries. These clamps help secure pipes in place, ensuring stability and support. The choice of materials for pipe strap clamps significantly impacts their performance and longevity.

Common materials include stainless steel, which offers high corrosion resistance and durability. According to industry reports, stainless steel clamps can increase lifespan by up to 50% in harsh environments. Additionally, carbon steel is used for its strength, though it may require protective coatings to prevent rust. Aluminum offers a lightweight alternative, yet it does not always withstand heavy loads effectively.

Not all materials suit every application. For example, PVC clamps provide insulation against electrolysis. However, they may not handle high temperatures well. In some cases, poor material choice leads to frequent replacements. While certain materials excel, they must align with specific project requirements. The choice can seem daunting, illustrating the need for careful consideration in clamp selection.

| Material Type | Common Uses | Advantages | Disadvantages |

|---|---|---|---|

| Steel | Heavy-duty applications, construction | Strong, durable, good for high-pressure pipes | May rust if not galvanized |

| Aluminum | Lightweight structures, HVAC systems | Lightweight, corrosion-resistant | Less strength compared to steel |

| Plastic (PVC) | Water pipes, drainage systems | Corrosion-resistant, lightweight | Not suitable for high temperatures or high pressure |

| Stainless Steel | Food and beverage industries, chemical applications | Highly resistant to corrosion, long lifespan | Higher cost than regular steel |

| Bronze | Marine applications, pipe fittings | Good resistance to seawater, durable | More expensive than other materials |

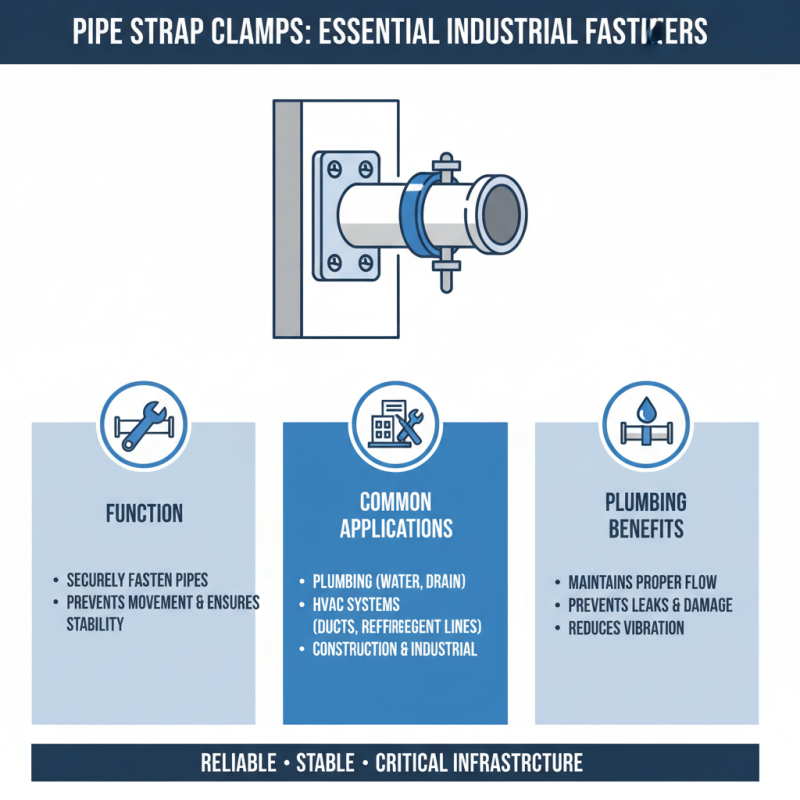

Pipe strap clamps are essential tools in many industries. They securely fasten pipes to walls, ceilings, or frameworks. This ensures stability and prevents movement. Common applications of these clamps include plumbing, HVAC systems, and construction projects. In plumbing, they hold water pipes in place. This helps maintain proper flow and prevents leaks.

HVAC systems also rely on pipe strap clamps. They support ducts and refrigerant lines. Proper support is crucial for efficiency. In construction, they can secure scaffolding or supports. This usage emphasizes safety. However, proper installation is key. Incorrectly installed clamps can cause issues. They may loosen over time or fail to support the intended load.

The simplicity of pipe strap clamps is both an advantage and a drawback. While they are easy to install, they may not always provide the strength needed. Users should evaluate their specific requirements. Over time, clamps can wear or rust, leading to potential failures. Regular checks can help avoid future dilemmas. Understanding the limitations of these clamps is as important as knowing their uses.

Pipe strap clamps are commonly used to secure pipes in place. Their installation process is vital to ensure safety and functionality. This process may seem straightforward, but it requires attention to detail.

To start, ensure you have the right tools. A standard set typically includes a drill, screws, and a wrench. According to industry reports, improper installation accounts for up to 30% of pipe failures. This underlines the need for a meticulous approach.

Position the clamp around the pipe. It should fit snugly without causing damage. Tighten the screws to secure the clamp, but avoid over-tightening, which can lead to stress fractures in the pipe. Aiming for a proper torque level, around 40-50 inch-pounds, is recommended. Check the alignment before finalizing. Uneven placement can create long-term issues. Ultimately, even small mistakes in this process can lead to significant problems down the line.

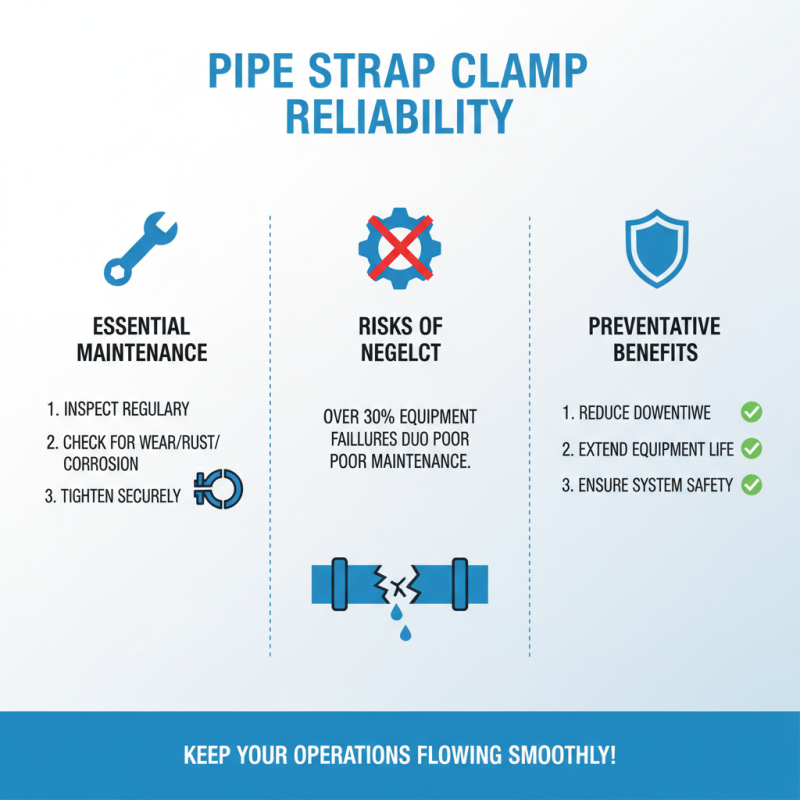

Pipe strap clamps are essential for securing pipes in place. However, regular maintenance is crucial for their reliability. According to industry surveys, over 30% of equipment failures are due to inadequate maintenance. Inspecting clamps for wear, rust, or corrosion can prevent costly downtime.

Another critical aspect is installation safety. Incorrectly installed clamps can lead to leaks or bursts, causing hazards. It’s important to follow manufacturer guidelines. Reports suggest that alignment errors account for 15% of installation errors. Always verify that the clamp is fitted correctly and tight enough to avoid issues.

In terms of materials, using high-quality straps is vital. They should be appropriate for the specific environment, especially in industrial settings. Studies indicate that about 20% of clamp failures occur due to material fatigue. Keep records of installations and inspections. Regularly checking your equipment can make a significant difference in safety and performance.