In the evolving landscape of plumbing solutions,

"No Hub Coupling" is gaining significant attention as a pivotal technology that enhances efficiency and reliability in systems installation.

According to a report by the Plumbing Manufacturers International (PMI), the adoption of innovative coupling methods, like no hub coupling, can reduce installation time by up to

40%, leading to substantial cost savings for contractors and builders alike. Furthermore, the use of no hub systems minimizes the risk of leaks and provides flexibility in pipe configurations, which is crucial as urban infrastructures demand more versatile plumbing systems to adapt to growing populations. As we delve into understanding No Hub Coupling, this guide will explore its advantages, installation techniques, and the future potential it holds for revolutionizing plumbing practices across both residential and commercial settings.

In the evolving landscape of plumbing solutions,

"No Hub Coupling" is gaining significant attention as a pivotal technology that enhances efficiency and reliability in systems installation.

According to a report by the Plumbing Manufacturers International (PMI), the adoption of innovative coupling methods, like no hub coupling, can reduce installation time by up to

40%, leading to substantial cost savings for contractors and builders alike. Furthermore, the use of no hub systems minimizes the risk of leaks and provides flexibility in pipe configurations, which is crucial as urban infrastructures demand more versatile plumbing systems to adapt to growing populations. As we delve into understanding No Hub Coupling, this guide will explore its advantages, installation techniques, and the future potential it holds for revolutionizing plumbing practices across both residential and commercial settings.

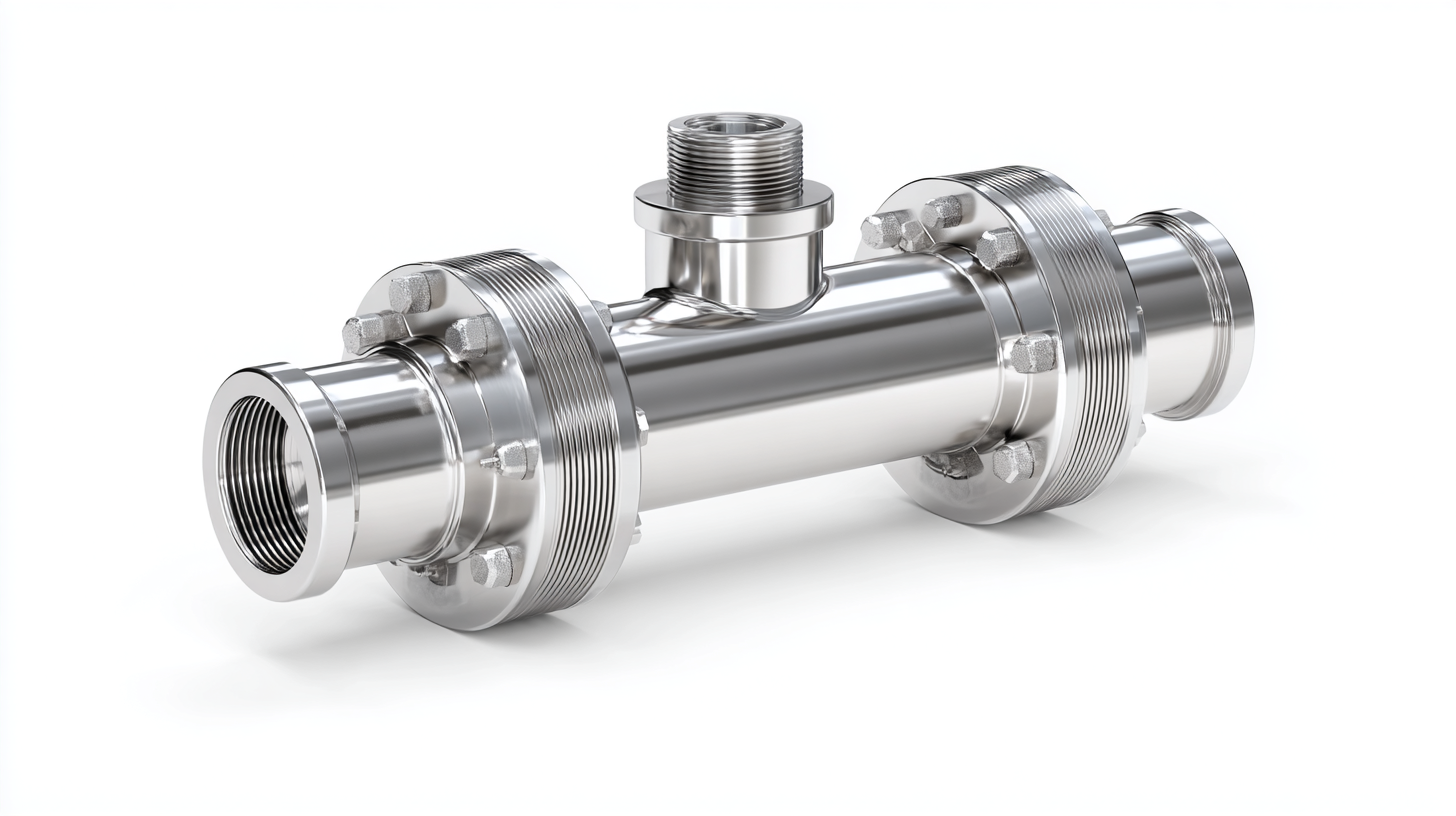

No hub coupling, a key innovation in plumbing systems, is rapidly gaining traction due to its efficiency and reliability. This coupling method connects pipes without the need for additional fittings, which significantly reduces the risk of leaks and simplifies installation. According to a report from the American Society of Plumbing Engineers, no hub coupling can decrease installation time by up to 50%, allowing contractors to complete projects faster and more cost-effectively.

The design of no hub coupling also contributes to its effectiveness. It utilizes a rubber gasket and a stainless-steel band, which provides a secure seal even under varying pressures. Research conducted by the International Association of Plumbing and Mechanical Officials indicates that this technology minimizes potential failures associated with traditional methods, enhancing the overall durability of piping systems. As the plumbing industry continues to advance, no hub coupling stands out as a fundamental solution that meets the demands for efficiency and sustainability in modern construction practices.

| Feature | Description | Benefits | Applications |

|---|---|---|---|

| Design | No hub coupling features a hubless design that allows for easier installation. | Faster installation reduces labor costs. | Residential and commercial plumbing. |

| Material | Typically made from durable materials like PVC or cast iron. | Long-lasting and resistant to corrosion. | Drainage systems in buildings. |

| Flexibility | Allows for adjustments and connections in tight spaces. | Enhances design flexibility in plumbing layouts. | Complex plumbing configurations. |

| Maintenance | Easier to access for repairs and replacements. | Reduced downtime during maintenance activities. | Both residential and industrial installations. |

| Cost | Potentially lower overall costs due to the efficiency of installation. | Cost-effective solution for plumbing needs. | New constructions and retrofitting projects. |

No hub coupling is increasingly recognized for its advantages in plumbing systems, particularly in enhancing water flow efficiency. One of the primary benefits of no hub coupling is its ability to facilitate a smooth and unobstructed water passage. According to a report by the Plumbing Efficiency Research Coalition, systems utilizing no hub coupling can reduce water friction loss by up to 20%. This reduction not only optimizes the water flow but also minimizes energy consumption required for pumps and heating systems, contributing to overall system efficiency.

Moreover, the installation of no hub coupling can significantly decrease the likelihood of leaks and maintenance issues. The no hub design allows for easier adjustments and faster installation, as it eliminates the need for traditional fittings and joints. A study from the American Society of Plumbing Engineers highlighted that using no hub couplings can reduce labor costs by approximately 15%, making it an economically sensible choice for both new constructions and renovations. With increasing emphasis on both sustainability and cost-effectiveness in plumbing solutions, no hub coupling stands out as a forward-thinking option in the quest for efficient water flow.

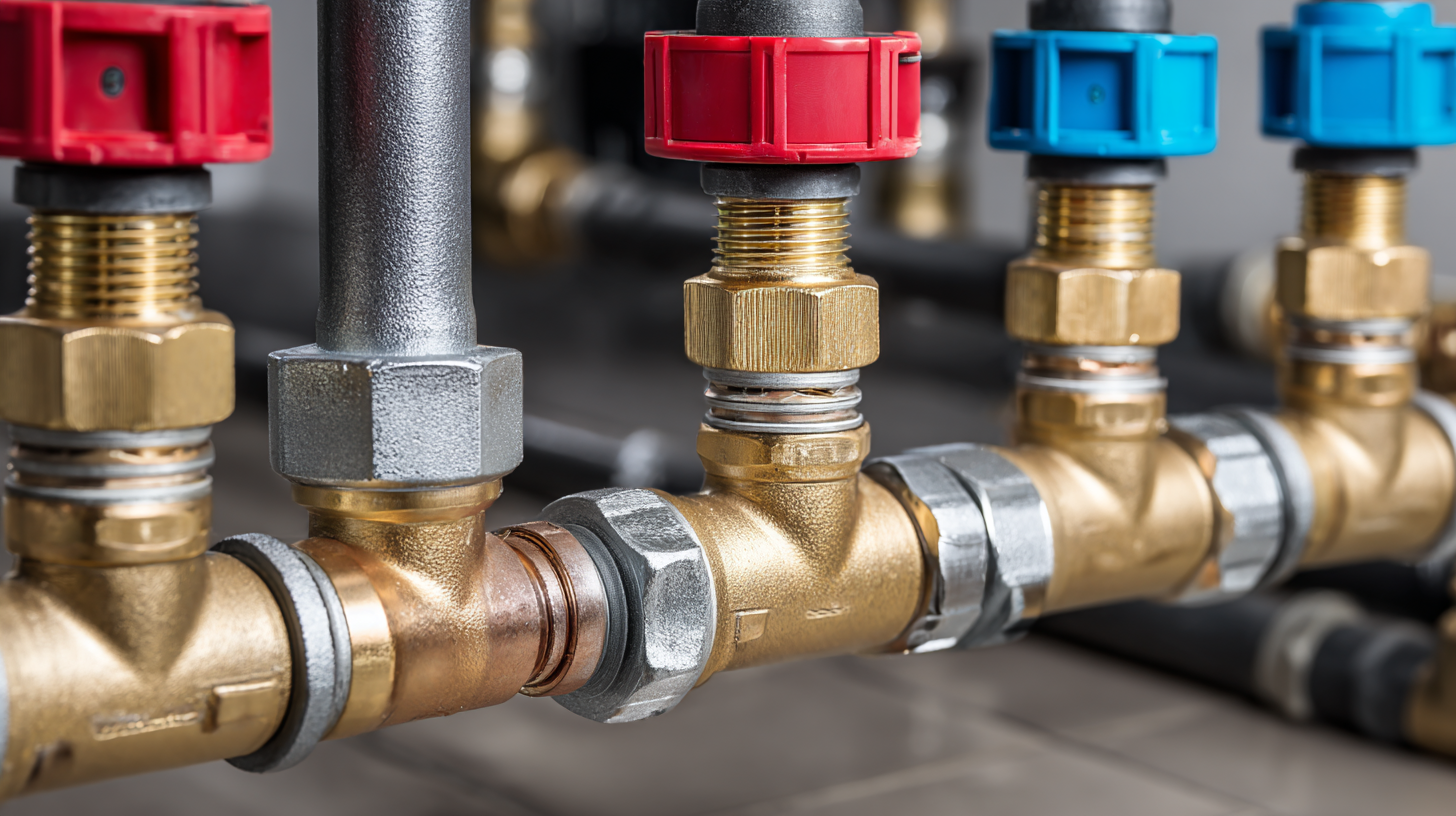

No hub coupling is revolutionizing plumbing systems by offering a streamlined, reliable solution that simplifies connections without the need for traditional fittings. This method greatly enhances efficiency, reducing the potential for leaks and improving the overall durability of plumbing installations. The ease of installation makes it an appealing choice for both professional plumbers and DIY enthusiasts.

When undertaking a no hub coupling installation, it’s essential to follow a few key tips to ensure a successful outcome. First, make sure to choose the right materials; selecting high-quality couplings will contribute to a more reliable connection. Next, prepare the pipes by ensuring they are clean and free of debris to promote a secure fit. Use a lubricant for the couplings to ease the installation process. Additionally, pay close attention to the alignment of the pipes; misalignment can lead to leaks. Finally, after installation, conduct a pressure test to verify the integrity of the joints.

By incorporating no hub coupling into your plumbing projects, you can achieve efficient and durable solutions that stand the test of time, setting a new standard in residential and commercial plumbing practices.

No hub coupling systems have gained immense popularity for plumbing solutions due to their efficiency and ease of installation. However, there are common pitfalls that users must avoid to ensure an optimal performance. One major mistake is the failure to properly clean and prepare the surfaces before installation. According to industry studies, residue on pipes can significantly hinder the effectiveness of the coupling, leading to potential leaks and costly repairs.

Additionally, incorrect sizing is another prevalent issue. The American Society of Mechanical Engineers (ASME) highlights that using improperly sized couplings can result in mechanical failures. A detailed report noted that around 30% of plumbing failures are attributed to sizing errors. To mitigate this, it’s crucial to always reference the manufacturer’s guidelines to select the right coupling size for specific pipe dimensions.

Additionally, incorrect sizing is another prevalent issue. The American Society of Mechanical Engineers (ASME) highlights that using improperly sized couplings can result in mechanical failures. A detailed report noted that around 30% of plumbing failures are attributed to sizing errors. To mitigate this, it’s crucial to always reference the manufacturer’s guidelines to select the right coupling size for specific pipe dimensions.

Finally, neglecting to monitor the installation process can lead to oversight in securing the joints adequately. Adequate tensioning is vital in avoiding joint separation or slippage, which are common in improperly installed no hub systems. By safeguarding against these mistakes, users can significantly enhance the longevity and reliability of their plumbing systems.

No hub coupling technology is revolutionizing plumbing systems by offering a flexible, efficient solution that addresses both performance and installation challenges. According to a report by the American Society of Plumbing Engineers, around 40% of plumbing failures result from the improper installation of traditional joints. In contrast, no hub coupling systems are designed to simplify the assembly process, allowing for quicker installations and improved reliability. This innovation reduces the risk of leakage and enhances system longevity, a critical factor for both residential and commercial plumbing applications.

No hub coupling technology is revolutionizing plumbing systems by offering a flexible, efficient solution that addresses both performance and installation challenges. According to a report by the American Society of Plumbing Engineers, around 40% of plumbing failures result from the improper installation of traditional joints. In contrast, no hub coupling systems are designed to simplify the assembly process, allowing for quicker installations and improved reliability. This innovation reduces the risk of leakage and enhances system longevity, a critical factor for both residential and commercial plumbing applications.

Moreover, the energy efficiency of no hub coupling technology cannot be overlooked. A study published in the Plumbing Industry Leadership Coalition highlights that this technology can reduce water flow resistance by up to 25%, leading to lower operational costs and decreased water waste in plumbing systems. As the industry moves toward more sustainable solutions, integrating no hub coupling can significantly contribute to water conservation efforts. These advancements indicate a promising future where plumbing systems are not only resilient but also environmentally friendly, aligning with global efforts to improve resource management.