In the competitive landscape of plumbing and construction, maximizing efficiency in installation and maintenance processes is paramount. A crucial component often overlooked in this equation is the Pipe Strap, which plays a vital role in securing piping systems to walls, ceilings, and other structural supports. According to the latest industry reports, proper usage of Pipe Straps can improve system stability by up to 30%, significantly reducing the risk of failure and subsequent repair costs.

In the competitive landscape of plumbing and construction, maximizing efficiency in installation and maintenance processes is paramount. A crucial component often overlooked in this equation is the Pipe Strap, which plays a vital role in securing piping systems to walls, ceilings, and other structural supports. According to the latest industry reports, proper usage of Pipe Straps can improve system stability by up to 30%, significantly reducing the risk of failure and subsequent repair costs.

Additionally, a survey conducted by the American Society of Plumbing Engineers indicates that nearly 25% of plumbing issues arise from inadequate securing methods. By understanding the variations and specifications of Pipe Straps, professionals can enhance their approach, ensuring that their installations are not only compliant but also built to last.

This guide aims to provide essential tips and insights, enabling you to make informed decisions in selecting the most suitable Pipe Strap for your needs, thereby streamlining your project efficiency and longevity.

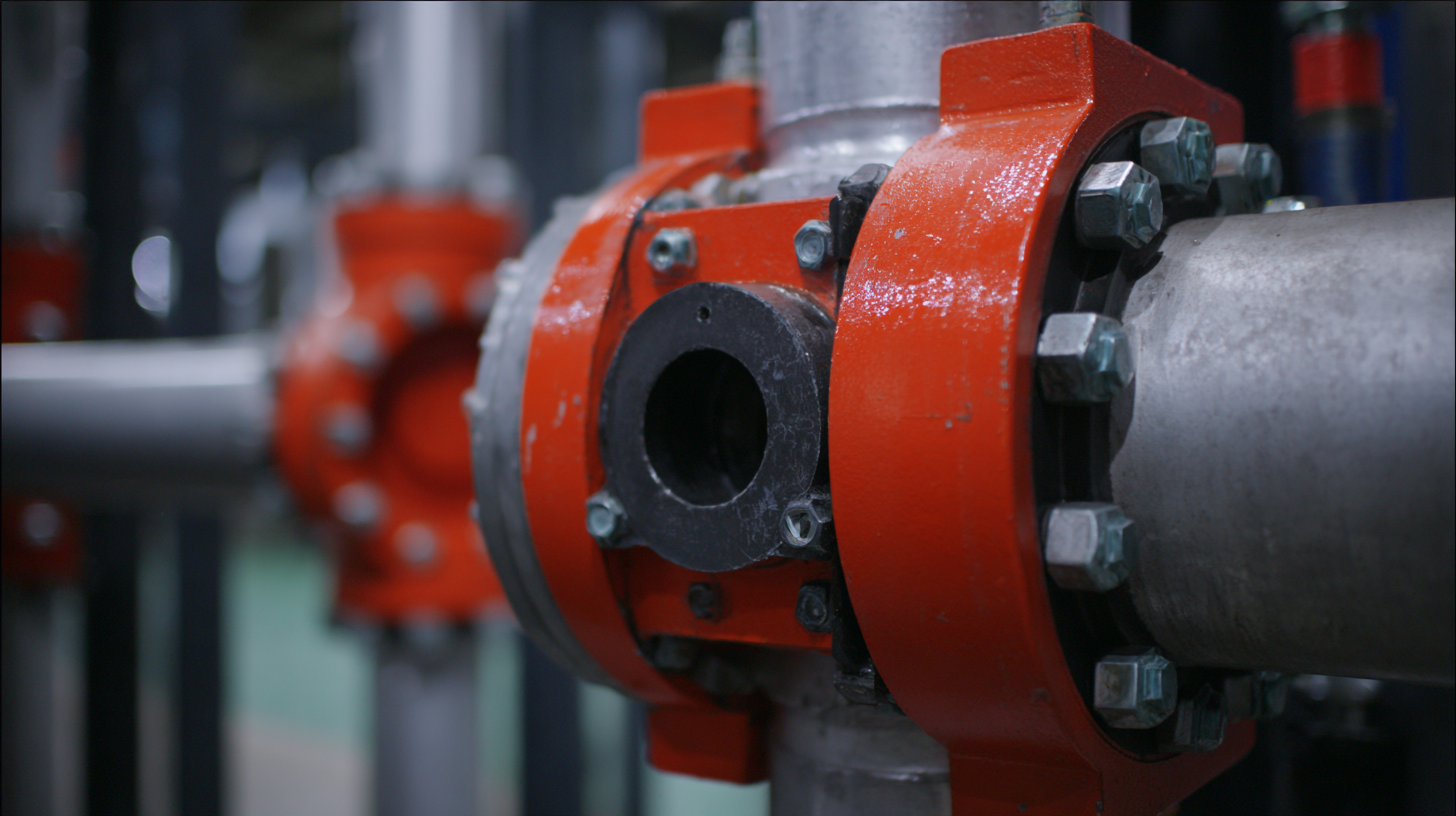

When selecting the right pipe strap, understanding the different types available is crucial for achieving optimal performance in various applications. Pipe straps can generally be categorized into several types, including plastic, metal, and composite materials. According to a report by the Global Pipe Support & Pipe Hanger Market Analysis, metal pipe straps, typically made of stainless steel or galvanized materials, are preferred in industrial settings due to their superior strength and resistance to corrosion, making them ideal for high-pressure and high-temperature environments.

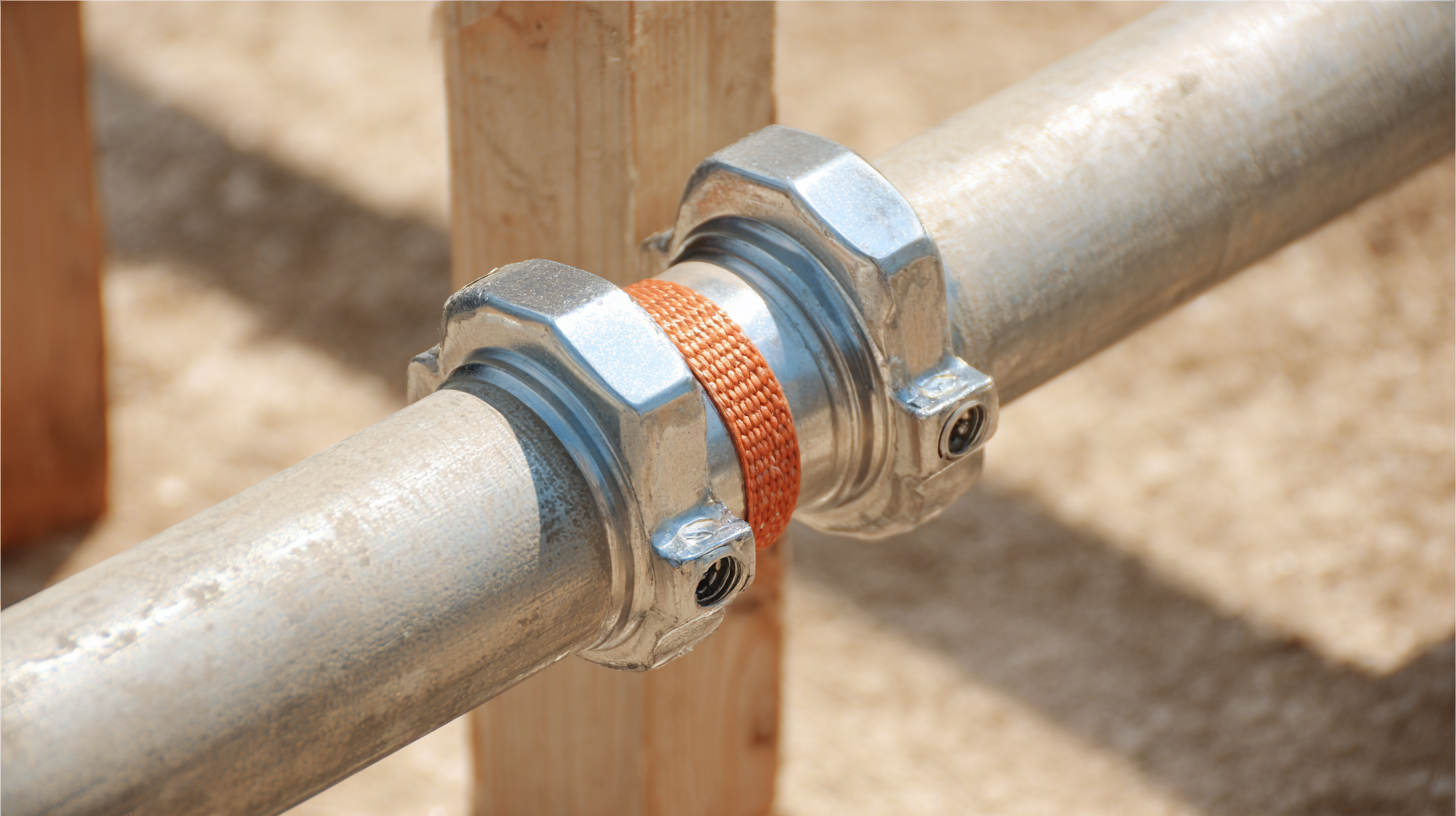

On the other hand, plastic pipe straps have gained traction in residential and light commercial applications where cost and ease of installation are key considerations. A study published by the American Society of Mechanical Engineers notes that plastic straps are lightweight and resistant to chemicals, which makes them suitable for HVAC systems and water pipes. Additionally, composite materials, combining the best properties of both metal and plastic, are emerging as a versatile option that provides a balance between durability and flexibility. Selecting the right type of pipe strap tailored to your specific needs not only maximizes operational efficiency but also extends the lifespan of your piping systems.

| Type of Pipe Strap | Material | Load Capacity (lbs) | Temperature Range (°F) | Recommended Use |

|---|---|---|---|---|

| Metal Pipe Strap | Steel | 200 | -50 to 500 | Heavy-duty applications |

| Plastic Pipe Strap | PVC | 75 | -20 to 140 | Plumbing and irrigation |

| Adjustable Pipe Strap | Stainless Steel | 150 | -30 to 400 | Variable pipe sizes |

| Insulated Pipe Strap | Rubber | 100 | -40 to 230 | Heat-sensitive pipes |

| Vibration Control Pipe Strap | Neoprene | 50 | -20 to 200 | High vibration areas |

When selecting pipe straps for your projects, certain key factors must be prioritized to maximize efficiency and effectiveness. The material of the strap, for instance, plays a crucial role in determining its durability and suitability for specific applications.

According to industry reports, stainless steel straps are commonly recommended for their high resistance to corrosion, particularly in harsh environments, while plastic straps may be preferred for lightweight and non-corrosive applications.

Additionally, the load capacity of the pipe strap is essential for ensuring safety and reliability. Research indicates that the proper selection of straps can significantly impact the overall structural integrity of piping systems. Straps must be chosen based on the weight and dimensions of the pipes they will support, as well as the external conditions they will face.

Advanced engineering solutions, such as the integration of innovative materials and designs, have emerged as a trend in the pipe strap market that promises enhanced performance and longevity, ultimately leading to reduced maintenance costs and improved operational efficiency.

When it comes to choosing the right pipe strap, understanding the different materials available is crucial for ensuring efficiency and durability in various applications. Metal pipe straps, typically made of stainless steel or galvanized steel, are favored for their strength and resistance to corrosion, making them ideal for outdoor and industrial settings. They provide a secure hold for heavy pipes, ensuring stability even under extreme conditions. However, their rigidity may not be suitable for all applications, requiring careful consideration of the specific requirements.

On the other hand, flexible materials like nylon or polyethylene straps offer a lightweight alternative that is easy to install. These straps are perfect for indoor use or applications where pipes need to be anchored securely without applying excessive pressure. They allow for some movement, accommodating thermal expansion and contraction—an essential feature in plumbing systems. In more specialized environments, such as HVAC systems, rubber-coated straps provide both grip and cushioning, reducing wear on the pipes while minimizing vibration. By thoroughly analyzing the characteristics and applications of various pipe strap materials, users can select the optimal solution for their needs.

This chart compares the tensile strength, cost per unit, and temperature resistance of various pipe strap materials commonly used in industry applications.

When selecting a pipe strap, the design plays a critical role in enhancing both the longevity and reliability of piping systems. Some of the top designs in the industry include heavy-duty stainless steel straps, which are known for their resistance to corrosion and ability to withstand extreme temperatures. According to a report by the Pipe Support Institute, stainless steel components can increase the lifespan of piping systems by up to 30% when properly installed, making them a preferred choice for industrial applications where durability is paramount.

Rubber-lined pipe straps are another excellent option, providing insulation and vibration dampening. These designs help to prevent damage from thermal expansion and contraction, thereby minimizing wear on the pipes. Research from the American Society of Mechanical Engineers indicates that utilizing rubber-lined options can reduce maintenance costs by upwards of 25%, as they mitigate the risk of leaks and subsequent repairs. This makes them ideal for environments where pipes are subjected to dynamic loads or constant movement.

Lastly, adjustable pipe straps provide versatility and convenience in installation. They allow for easy adjustments during maintenance or repositioning of piping without the need for complete disassembly. Industry insights suggest that using adjustable designs can lead to a 15% reduction in installation time, enabling quicker project turnaround while ensuring that the piping system remains securely fastened. Choosing the right pipe strap not only optimizes operational efficiency but also significantly impacts the overall cost-effectiveness of the piping infrastructure.

When selecting pipe straps, cost-effectiveness is a key consideration that can significantly impact your project’s overall budget. Understanding the specific needs of your application, including load capacity, material durability, and environmental factors, will allow you to make informed decisions. For instance, opting for higher-quality materials may incur a higher initial cost, but their longevity and reliability can save you money on replacements and maintenance in the long run.

Additionally, it’s essential to compare different brands and their offerings to find the best value. Look for suppliers who provide detailed specifications, warranties, and customer support. These elements can enhance your shopping experience and ensure you make a wise investment. By weighing the upfront costs against potential future savings, you can effectively choose pipe straps that fit within your budget while maximizing performance and durability.