In the realm of modern mechanical systems, the integration of advanced components has become increasingly essential for optimal performance and reliability. One such crucial component is the Hub Coupling, which plays a pivotal role in facilitating efficient power transmission between various machine elements. This article delves into the significance of Hub Coupling, highlighting its functionality, types, and advantages in enhancing mechanical system performance. By understanding the intricacies of Hub Coupling, engineers and designers can make informed decisions that not only improve system efficiency but also reduce operational costs and maintenance challenges. With a focus on practical tips and best practices, this exploration aims to shed light on the indispensable role of Hub Coupling in contemporary engineering applications, thus guiding professionals in leveraging this technology for superior mechanical design and operational success.

In the realm of modern mechanical systems, the integration of advanced components has become increasingly essential for optimal performance and reliability. One such crucial component is the Hub Coupling, which plays a pivotal role in facilitating efficient power transmission between various machine elements. This article delves into the significance of Hub Coupling, highlighting its functionality, types, and advantages in enhancing mechanical system performance. By understanding the intricacies of Hub Coupling, engineers and designers can make informed decisions that not only improve system efficiency but also reduce operational costs and maintenance challenges. With a focus on practical tips and best practices, this exploration aims to shed light on the indispensable role of Hub Coupling in contemporary engineering applications, thus guiding professionals in leveraging this technology for superior mechanical design and operational success.

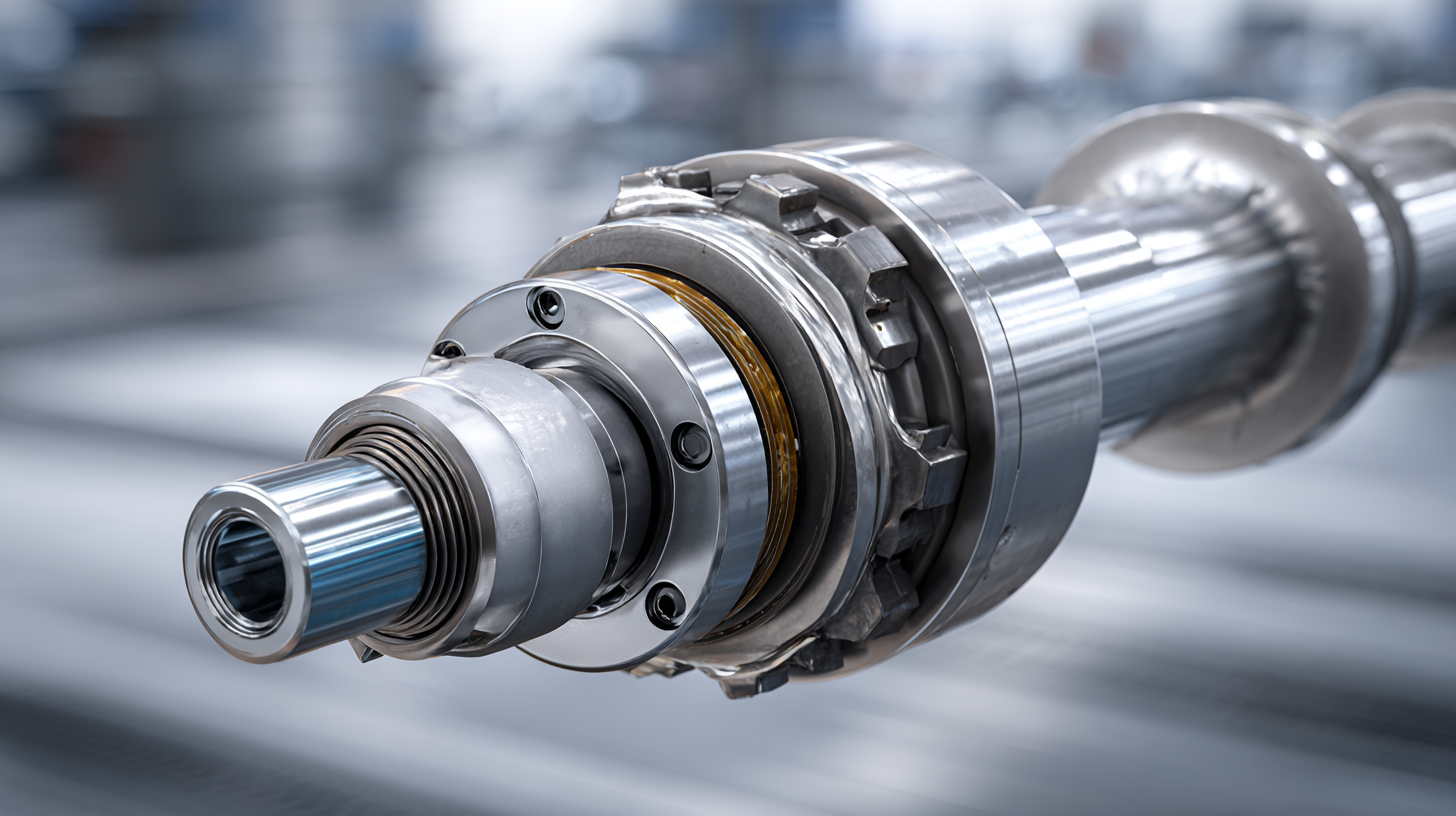

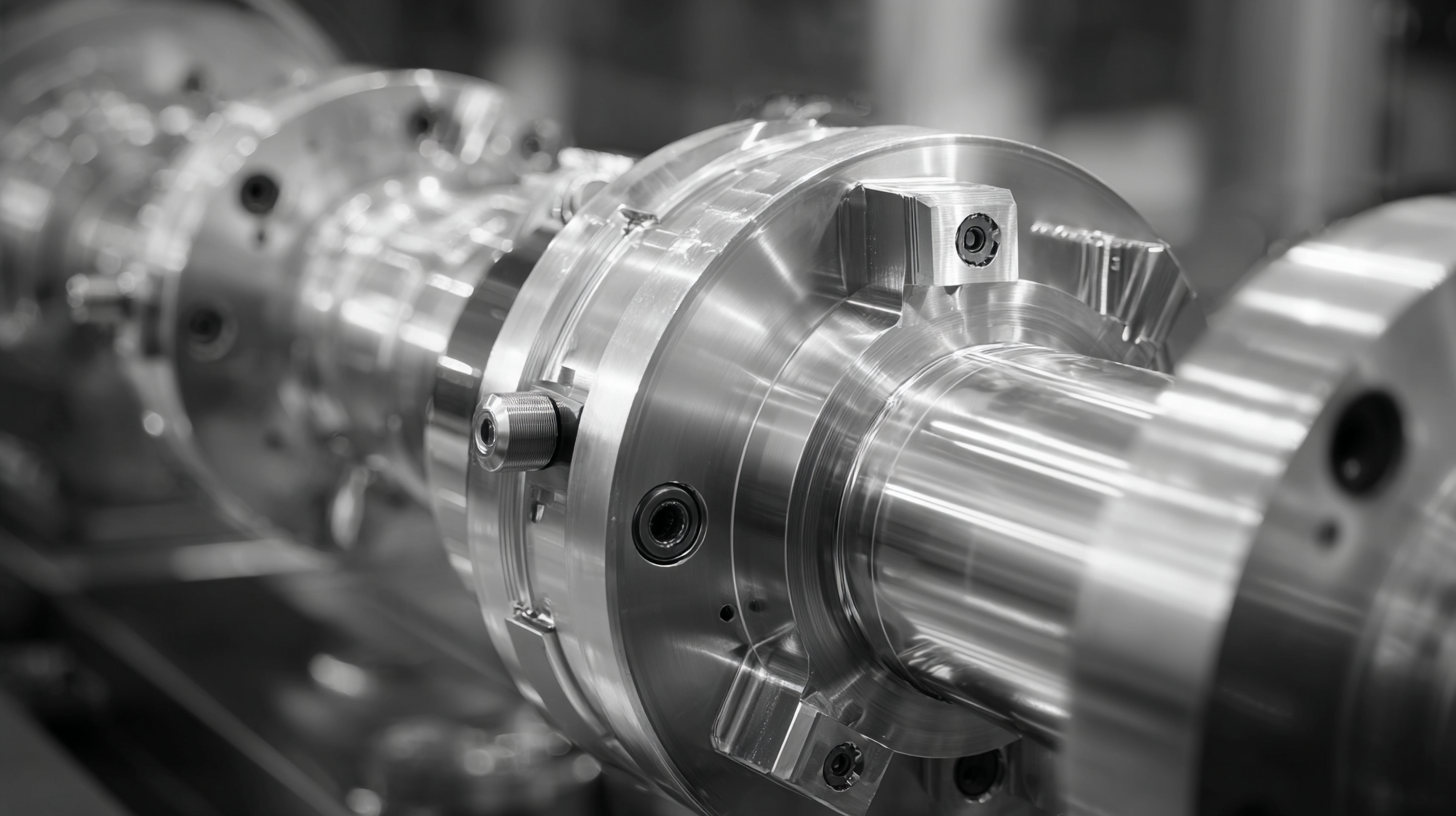

Hub coupling plays a crucial role in enhancing mechanical efficiency within modern applications. These components are designed to connect rotating shafts while accommodating misalignments and mitigating vibrations. By allowing for some flexibility between the connected shafts, hub couplings reduce wear and tear, prolonging the lifespan of mechanical systems and ensuring smoother operation. This adaptability is especially important in dynamic environments where precise alignment can be challenging, such as in manufacturing plants and automotive applications.

Moreover, the integration of advanced materials and designs in hub couplings contributes to significant improvements in operational performance. High-strength materials and innovative engineering have resulted in couplings that can withstand higher torque and load requirements while minimizing weight and energy losses. As a result, systems utilizing these modern hub couplings exhibit enhanced power transfer efficiency, leading to reduced energy consumption and lower operational costs. In an era where sustainability and efficiency are paramount, the importance of hub couplings cannot be overstated, making them indispensable in the design of contemporary mechanical systems.

In recent years, the adoption of hub coupling technologies has been increasingly trending across various mechanical systems, driven by the need for enhanced efficiency and reliability. As industries integrate more sophisticated technologies, the significance of effective power transmission has come to the forefront. Reports indicate a significant growth trajectory for sectors utilizing hub couplings, with market projections suggesting that as more businesses recognize the advantages of these systems, their adoption rates will continue to rise.

Particularly notable are the growth forecasts across different markets, such as the global sensor market, expected to expand from $258.47 billion in 2025 to an impressive $457.26 billion by 2032. Similarly, the industrial robots market in the Asia-Pacific region is predicted to surge from $10.98 billion in 2025 to $23.31 billion by 2033. These trends reflect a broader industrial movement towards enhanced automation and efficiency, making the role of hub couplings in modern mechanical systems more critical than ever. As industries evolve, understanding and leveraging these mechanical solutions will become essential for remaining competitive in a rapidly changing market landscape.

| Year | Hub Coupling Adoption Rate (%) | Market Growth Rate (%) | Key Industries using Hub Couplings |

|---|---|---|---|

| 2021 | 25% | 5% | Manufacturing, Automotive |

| 2022 | 30% | 6% | Aerospace, Robotics |

| 2023 | 35% | 7% | Energy, Construction |

| 2024 | 40% | 8% | Chemicals, Pharmaceuticals |

| 2025 | 50% | 9% | Marine, Defense |

The comparative analysis of hub coupling and traditional coupling solutions holds significant relevance in modern mechanical systems. Hub coupling systems are known for their efficiency in power transmission, reducing energy loss typically associated with conventional couplings. This advancement is crucial in sectors where maximizing output while minimizing energy consumption is a priority, such as in hybrid renewable energy systems combining solar and wind technologies. These systems face various challenges, and effective coupling methods can enhance overall system reliability and performance.

In contrast, traditional coupling methods often lack the adaptability required for contemporary demands. Issues such as misalignment and vibration can lead to reduced operational efficiency and increased maintenance costs. A recent study comparing coupling solutions highlights the advantages of direct coupling techniques in various applications, suggesting that innovative approaches like hub coupling can significantly streamline processes, particularly in large-scale setups such as photovoltaic and battery energy storage systems. This ongoing evolution in mechanical coupling technologies signifies a necessary shift towards more efficient, integrated solutions that not only improve operational stability but also support sustainable energy initiatives.

Hub coupling is an integral component in modern mechanical systems, significantly enhancing load distribution and vibration control. By effectively connecting two shafts, hub couplings help ensure that the distributed loads are managed evenly across the system. This uniform distribution minimizes stress concentrations, which can lead to premature wear and failure of the components, ultimately prolonging the life cycle of machinery and reducing maintenance costs.

Hub coupling is an integral component in modern mechanical systems, significantly enhancing load distribution and vibration control. By effectively connecting two shafts, hub couplings help ensure that the distributed loads are managed evenly across the system. This uniform distribution minimizes stress concentrations, which can lead to premature wear and failure of the components, ultimately prolonging the life cycle of machinery and reducing maintenance costs.

Tip: When selecting a hub coupling, consider the material's stiffness and the design of the coupling itself. A well-designed coupling absorbs vibrations efficiently, improving overall system stability and performance.

Furthermore, vibration control is crucial in high-speed applications where resonance may occur. Hub couplings can be engineered to dampen vibrations, reducing the risk of damaging impacts on gears and bearings. This feature is especially relevant for equipment operating under variable loads, providing a smoother operation and enhancing user comfort and safety.

Tip: Regularly inspect hub couplings for signs of wear and misalignment to maintain optimal performance and prevent operational issues.

Hub coupling plays a pivotal role in modern mechanical systems across various sectors, enhancing efficiency and performance. In the automotive industry, for instance, a study by the Society of Automotive Engineers (SAE) reported that implementing advanced hub couplings can improve power transmission efficiency by up to 15%. This enhancement is crucial in electric vehicles (EVs), where reducing energy losses directly correlates to extended battery life and improved range, a key consideration for consumers and manufacturers alike.

In the aerospace sector, data from the International Journal of Aerospace Engineering highlights that using hub couplings in rotorcraft significantly reduces vibration and noise levels during flight, leading to smoother operations. A notable case study involving a leading helicopter manufacturer demonstrated that the integration of high-performance hub couplings resulted in a 25% decrease in maintenance costs over five years, showcasing their long-term economic benefits. Such implementations underscore the necessity of hub coupling technology in optimizing mechanical systems for various applications, underscoring its critical role in modern engineering advancements.