In the world of industrial and automotive applications, few components are as essential as a trusted fastening solution. The German Type Hose Clamp stands out as a staple in ensuring secure connections and leak prevention in various systems. According to Dr. Hans Müller, a leading expert in clamping technology, "The reliability of a hose connection directly impacts the overall performance of the machinery." His insights underline the critical nature of selecting the right hose clamp for specific applications.

As industries increasingly turn toward optimizing efficiency and safety, understanding the advantages of German Type Hose Clamps becomes imperative. These clamps are known for their robust construction, adjustable design, and ability to withstand a variety of environmental conditions. This guide aims to navigate through the best practices and considerations that should influence your decision-making process when purchasing these clamps. From material selection to installation techniques, we will explore how to maximize the effectiveness of your hose connections, ensuring longevity and reliability in every application. With the right knowledge, users can confidently choose the best clamps that meet their needs while minimizing potential risks.

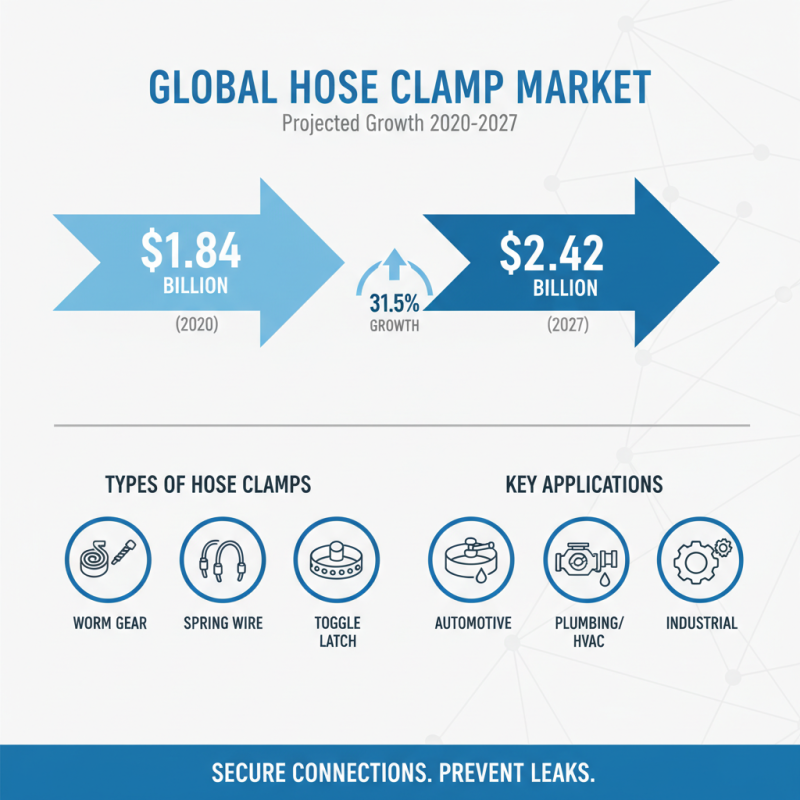

Hose clamps are essential components widely used in various industries, serving the critical function of securing hoses to fittings and preventing leaks. According to a report by Allied Market Research, the global hose clamp market was valued at approximately $1.84 billion in 2020 and is projected to reach around $2.42 billion by 2027, highlighting the increasing demand for these reliable fastening devices. Understanding the different types of hose clamps available is crucial for selecting the appropriate one for specific applications.

The most commonly used types of hose clamps include worm gear clamps, spring clamps, and oetiker clamps. Worm gear clamps are highly versatile and feature a metal band with a threaded screw, allowing for adjustable tension around the hose. Spring clamps, on the other hand, use tension provided by a spring mechanism, making them ideal for quick and repeated take-offs and installations. Oetiker clamps offer a durable, permanent solution with a design that secures the hose without requiring tools for installation. Industry data suggest that choosing the right clamp type based on application requirements can significantly affect the longevity and efficiency of hose assemblies, thus reducing downtime in industrial operations.

When selecting high-quality German hose clamps, several key features should be prioritized to ensure reliability and durability. One of the most critical aspects is the material used in the clamps. Premium clamps are typically made from stainless steel, which offers excellent resistance to corrosion and wear. This durability is vital for applications exposed to varying weather conditions and harsh environments. Additionally, look for clamps that feature a smooth finish and consistent thickness, which prevents damage to the hoses they are securing, offering a snug fit without risk of leaks.

Another essential characteristic is the design of the clamping mechanism. High-quality German hose clamps commonly feature a worm gear design that allows for precise adjustment and a firm grip on the hose. The ease of adjustment is crucial as it facilitates installation and ensures that the hose remains tightly secured under varying pressure conditions. Furthermore, the presence of a rubber or soft lining on the clamp can enhance grip while providing additional protection to the hose. This thoughtful combination of materials and design is what sets premium clamps apart, making them a worthwhile investment for ensuring optimal performance in any application.

When selecting the right hose clamp, it’s essential to consider the specific requirements of your application. First, assess the size and type of hose you are working with. Hose clamps come in various diameters and styles, such as worm drive, spring, and snap-on clamps, each suited for different hose materials and uses. Ensuring that you choose a clamp that fits snugly around the hose without damaging it is crucial for maintaining a secure seal and preventing leaks.

Another critical factor to consider is the material of the hose clamp itself. Depending on the environment in which the clamp will be used, you might prefer stainless steel for its corrosion resistance, especially in damp or corrosive settings. Alternatively, plastic clamps may be suitable for lighter-duty applications. It's also important to think about the installation process; some clamps require specific tools for tightening while others can be easily adjusted by hand. By carefully evaluating these factors, you can ensure that you select a hose clamp that will function effectively and provide long-lasting service.

| Clamp Size (mm) | Material Type | Application | Temperature Range (°C) | Maximum Pressure (Bar) |

|---|---|---|---|---|

| 16-25 | Stainless Steel | Automotive | -40 to 100 | 10 |

| 25-34 | Galvanized Steel | Industrial | -20 to 80 | 8 |

| 35-48 | Plastic | Agriculture | -10 to 65 | 5 |

| 48-60 | Stainless Steel | Marine | -30 to 90 | 12 |

| 60-75 | Aluminum | HVAC | -10 to 70 | 6 |

When it comes to hose clamps, German engineering is synonymous with

reliability and performance. A wide variety of German brands dominate the market,

providing various models tailored to different applications. Industry reports, such as those from the

European Hose Clamp Association, indicate that high-quality clamps,

particularly those produced in Germany, achieve a failure rate of less than 1% in critical installations,

which is significantly lower than the global average. This reliability makes German hose clamps particularly sought after

in automotive, industrial, and plumbing applications.

Among the most popular types of German hose clamps are the screw-type

and spring-type clamps. Screw-type clamps, known for

their ease of installation and adjustment, are often used in automotive applications where precise fit is crucial.

On the other hand, spring-type clamps are favored for their ability to maintain constant pressure and accommodate thermal

expansion, making them ideal for various industrial settings. According to recent market analyses,

the demand for these clamps has been rising steadily, with an estimated growth rate of 4.5%

annually as industries increasingly recognize the importance of high-quality fastening solutions for operational efficiency

and safety.

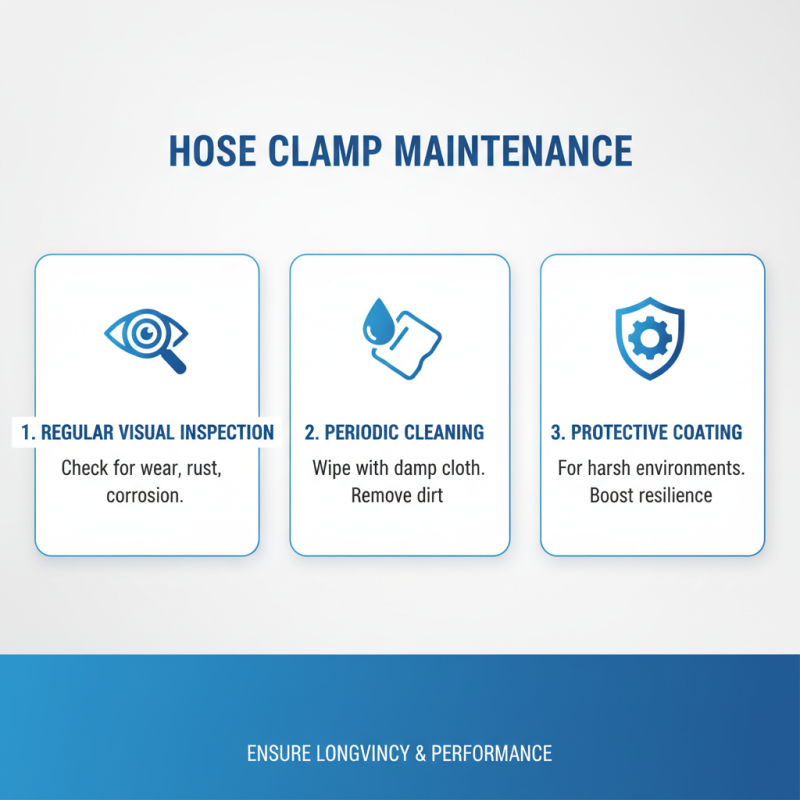

Proper maintenance of hose clamps is essential for ensuring their longevity and optimal performance. To begin with, regular visual inspections should be conducted to identify any signs of wear, rust, or corrosion. It's important to clean the clamps periodically using a damp cloth to remove dirt and debris that can contribute to deterioration. If clamps are exposed to harsh conditions such as extreme temperatures or corrosive environments, consider applying a protective coating to enhance their resilience against environmental factors.

Moreover, the correct installation of hose clamps is paramount for their durability. Ensure that each clamp is tightened according to the manufacturer's specifications, avoiding overtightening, which can damage the hose or the clamp itself. Using a torque wrench can provide accuracy in the tightening process. Additionally, periodic retightening should be performed to counteract any slack that may develop over time, especially in dynamic systems where vibration is present. Following these practices will not only extend the life of the hose clamps but also maintain the overall integrity of the connected systems.