Choosing the right riser clamp can be a daunting task. With so many options available, it’s easy to feel overwhelmed. A riser clamp is essential for securing pipes and cables in vertical spaces. It supports the weight and ensures stability.

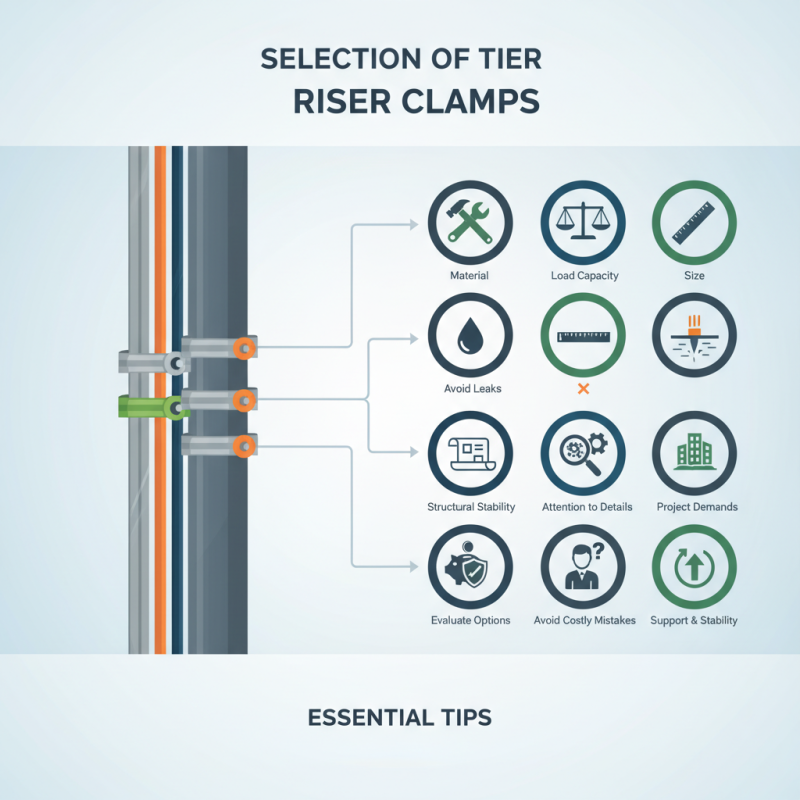

When selecting a riser clamp, consider your specific needs. Factors like material, load capacity, and size matter. A poorly chosen riser clamp may lead to problems down the line. It could cause leaks or even structural issues.

Understanding your project’s demands is crucial. Not every riser clamp is the same. By paying attention to details, you can make a more informed choice. Taking the time to evaluate your options will pay off. You want to avoid costly mistakes.

Riser clamps serve an essential function in supporting piping systems. They ensure that pipes remain securely in place, preventing damage and leaks. When selecting the right riser clamp, it's vital to understand the specific requirements of your project. Various materials and designs are available, each tailored to different applications. For instance, some clamps are better suited for heavy-duty usage, while others work well for lighter applications.

In addition to material choice, consider the size and weight of your pipes. A mismatch might lead to failures down the line. Installation ease also varies among designs. Some clamps are straightforward, while others may require specialized tools. It's critical to evaluate your team's capabilities. Testing different clamps on-site can reveal hidden challenges and areas for improvement. Pay attention to potential issues. Ignoring them might lead to complications later. Prioritize reliability and safety when making your selection.

This chart illustrates the importance of various factors to consider when choosing the right riser clamp. Each factor has been rated on a scale from 1 to 10, reflecting its significance in the selection process.

When choosing riser clamps, it's essential to understand the different types available. Riser clamps can vary widely in design and application. For instance, some clamps are specifically made to handle conduit, while others are perfect for pipes. Each type serves a particular purpose, so knowing your needs is crucial.

In your search for the right clamp, consider these tips. Assess the weight and size of the materials involved. A mismatch can lead to failures. Also, think about the environment. Are you working indoors or outdoors? Weather conditions can affect material choices. Visualizing these scenarios helps narrow down your options.

Lastly, always check the specifications. Many people overlook detail here. A clamp may look suitable but fail due to incorrect ratings. Reflect on your specific project requirements. Taking a moment to evaluate can save time and resources later. Finding the perfect riser clamp is about fitting the right tool to your situation.

When selecting the right riser clamp, evaluating load capacity is crucial. Different applications demand varying levels of strength. According to industry reports, certain designs can handle up to 1,200 pounds in optimal conditions. However, factors like wear and installation quality also affect performance. It’s vital to assess your specific needs and ensure the clamp can support the intended loads safely.

Material considerations play an equally important role. Common materials include stainless steel and aluminum, each offering distinct benefits. Stainless steel is known for its durability in harsh environments. Aluminum clamps, while lighter, may not support as much weight but are easier to install. Professionals recommend carefully analyzing the environment where the riser clamp will be used. For example, corrosive conditions can significantly reduce the lifespan of a clamp. If you overlook these factors, you may face unexpected failures, leading to costly repairs.

| Tip | Description | Load Capacity (lbs) | Material | Best Use Case |

|---|---|---|---|---|

| 1. Assess Load Requirements | Evaluate the maximum weight to be supported to choose a suitable riser clamp. | 200 - 500 | Steel | Heavy machinery installation |

| 2. Material Selection | Choose materials that resist corrosion and wear, based on environmental conditions. | 100 - 300 | Aluminum | Outdoor applications |

| 3. Check Compatibility | Ensure the clamp fits with existing systems and pipe sizes for secure installation. | 150 - 400 | Galvanized Steel | Piping systems |

| 4. Consider the Environment | Select clamps designed for specific conditions like moisture or extreme temperatures. | 250 - 600 | Stainless Steel | Marine applications |

| 5. Installation Method | Choose clamps that match the installation methods available at your location. | 100 - 350 | Plastic | DIY projects |

| 6. Ease of Adjustment | Select adjustable clamps for installations that may require future modifications. | 200 - 450 | Nylon | Temporary setups |

| 7. Safety Standards | Ensure the clamps meet relevant safety certifications for maximum reliability. | 150 - 600 | Chrome Plated | Industrial applications |

| 8. Ease of Maintenance | Opt for clamps that require minimal upkeep for long-term use. | 100 - 250 | Polymer | Light-duty applications |

| 9. Cost vs. Quality | Balance budget constraints with the quality of the clamps for longevity. | 300 - 800 | Steel Alloy | High-load scenarios |

| 10. Supplier Reputation | Invest in clamps from reputable suppliers for better reliability and support. | 250 - 700 | Reinforced Composite | Heavy industrial use |

When selecting a riser clamp, environmental factors play a critical role. Consider the installation setting, whether it's indoors or outdoors. For instance, a study by the National Fire Protection Association indicated that over 70% of installations faced issues due to corrosion when inappropriate materials were used. Riser clamps in humid environments require rust-resistant options.

Temperature variations also affect clamp performance. Research shows that materials can expand and contract, leading to potential failures if not properly accounted for. The American Society of Mechanical Engineers suggests that at least one-third of clamp failures result from thermal expansion miscalculations.

Installation requirements cannot be overlooked. A poorly installed riser clamp can lead to serious structural risks. Engineers often neglect proper spacing and alignment. Reports indicate that nearly 25% of misalignments occur during the installation phase. Awareness of local building codes is essential; failure to comply can lead to costly revisions.

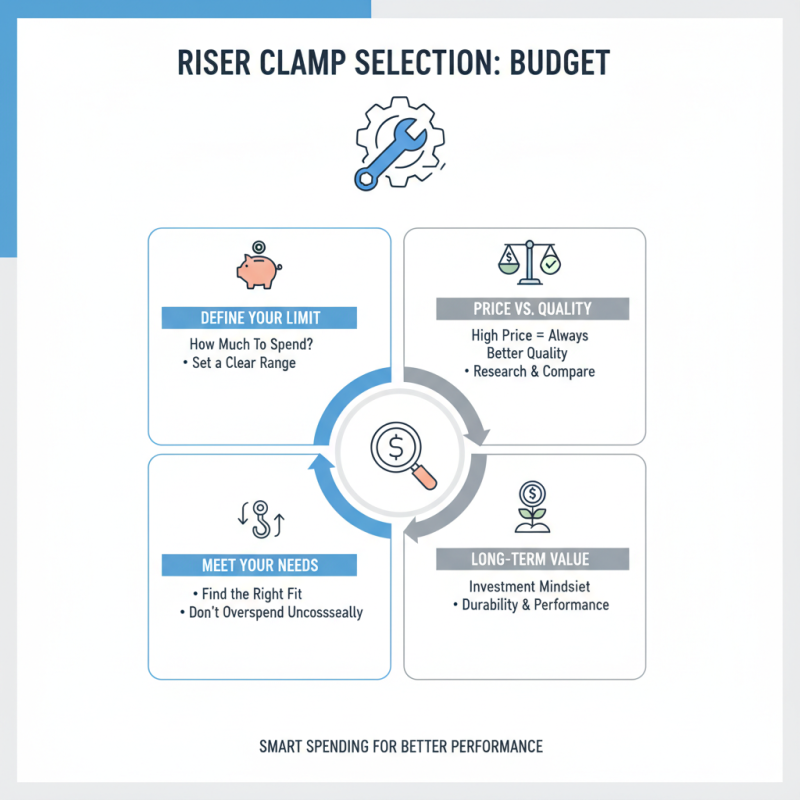

When selecting a riser clamp, budget is a critical factor. It’s essential to clearly define how much you are willing to spend. Prices can vary significantly, and a high price does not always guarantee quality. Look for options that fit your budget but also meet your needs. Sometimes, spending just a bit more can lead to a much better product. Consider the long-term value of your investment.

Brand reliability is another key aspect to consider. Established brands may offer reassurances through quality guarantees and customer support. However, newer brands might provide innovative solutions at competitive prices. Research reviews and testimonials to gauge user experiences. Trust can be subjective; what works for one may not work for another. Don’t solely rely on popularity; explore less-known brands that might surprise you with quality performance.

Navigating budget and brand can be tricky. You might find yourself sacrificing one for the other. This could lead to regrets down the line. Reflect on your choices. Analyze if you truly need specific features before committing. Sometimes, the chase for the best options can cloud judgment. Being clear about your priorities can ensure a better decision-making process.