Choosing the right hub coupling is a crucial decision that can significantly impact the efficiency of your machinery and systems. As industries evolve towards greater automation and precision in 2025, the demand for reliable and efficient power transmission solutions has never been higher. Hub couplings play a vital role in connecting various components, ensuring smooth operation while minimizing wear, vibration, and energy loss. A well-selected hub coupling can potentially boost your system's efficiency by an impressive 30%, making it essential for engineers and decision-makers to understand the factors at play.

In this article, we will explore ten essential tips for selecting the right hub coupling tailored to your specific needs. From understanding the different types of couplings available to evaluating their compatibility with existing systems, each tip will guide you toward making informed decisions that enhance both performance and longevity. By implementing these strategies, you will not only ensure seamless integration but also drive productivity improvements across your operations. Join us as we delve into the intricacies of hub coupling selection and discover how optimizing this critical component can lead to significant gains in efficiency and operational success.

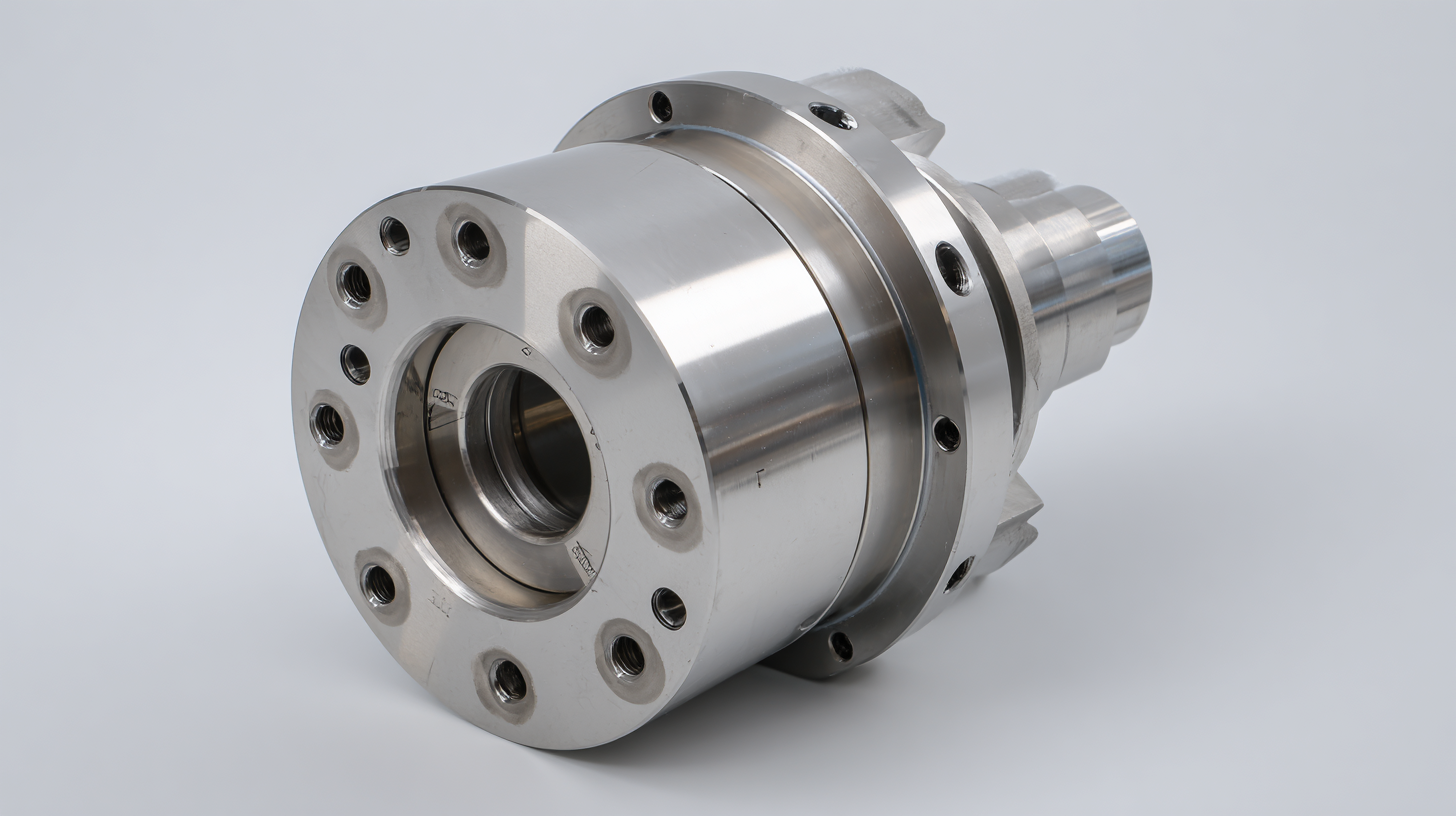

Hub couplings are essential components in various mechanical systems, serving as a connection between two shafts while allowing for slight misalignments.

Understanding the different types of hub couplings is crucial for selecting the right one for your application.

Common types include rigid couplings, flexible couplings, and tire couplings. Each type serves distinct purposes; for example, rigid couplings provide strong torque transmission and are ideal for applications requiring precise alignment, while flexible couplings can accommodate misalignments and reduce stress on the shafts.

In addition to the type of coupling, it’s important to consider their applications. Hub couplings are commonly found in industrial machinery, automotive systems, and power transmission setups. For instance, flexible couplings are often utilized in conveyor systems or pumps where vibration dampening and misalignment tolerance are necessary.

Understanding these nuances not only aids in choosing the appropriate coupling but also plays a crucial role in enhancing system efficiency, potentially boosting performance by up to 30%. Investing time in selecting the right hub coupling can lead to significant improvements in the overall functionality and longevity of mechanical systems.

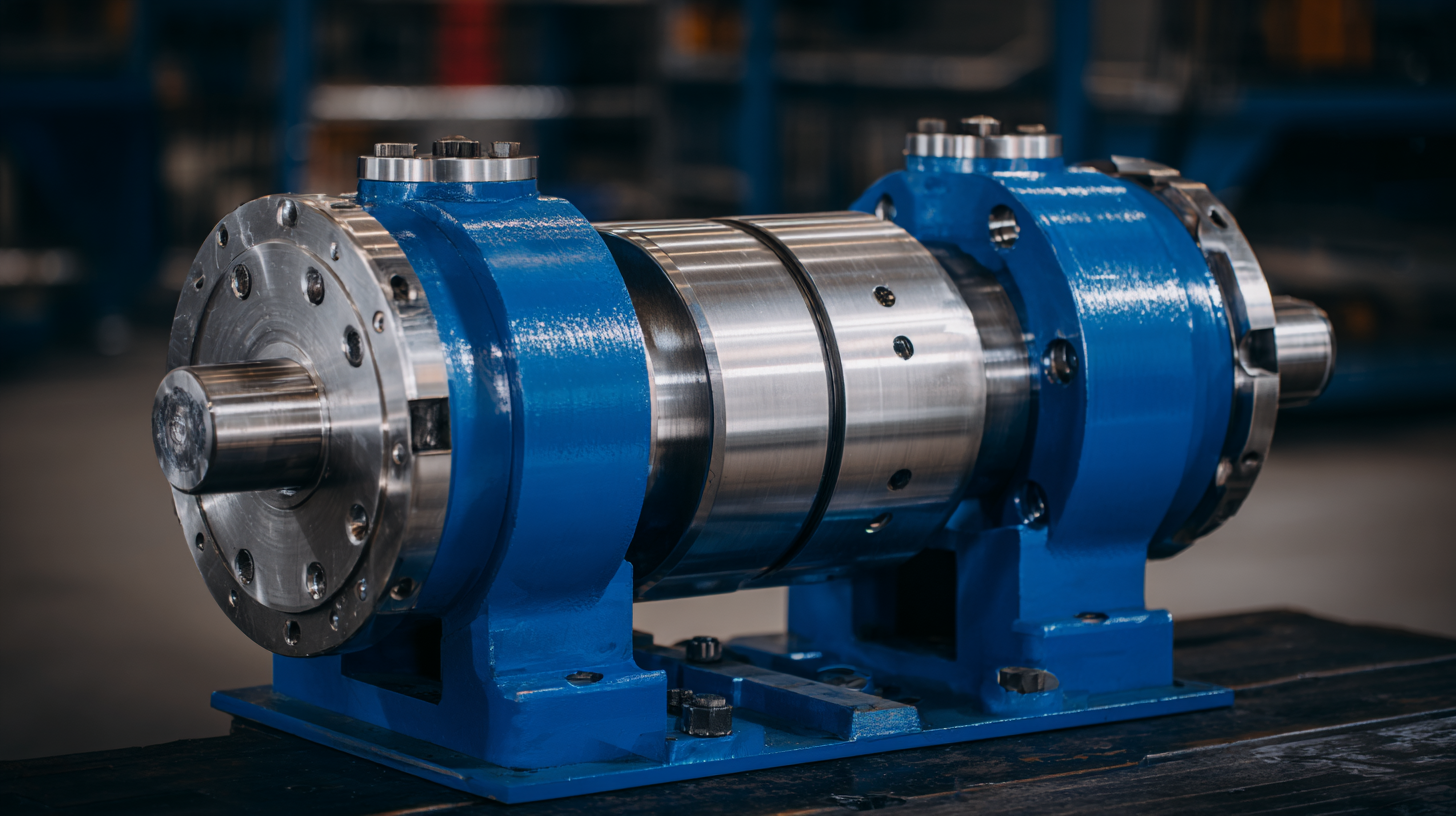

When selecting the right hub coupling, several key factors should be taken into account to ensure optimal performance and efficiency. First, consider the application requirements, including torque ratings and speed characteristics. Understanding the specific demands of your machinery will help in choosing a coupling that can handle the operational stresses without failing. Additionally, compatibility with existing components is crucial; ensure that the coupling's dimensions and materials align with those of your driving and driven equipment to prevent premature wear or unexpected down-time.

Another important aspect is the type of coupling required for your application. There are various designs such as rigid, flexible, or disc couplings, each offering distinct advantages depending on the operational conditions. Flexible couplings, for instance, can accommodate misalignments and reduce vibrations, making them suitable for high-speed applications. Moreover, consider the environmental factors, such as temperature and exposure to chemicals, as these can influence the performance and lifespan of the coupling. By thoroughly evaluating these factors, you position your machinery for enhanced efficiency and reliability in its operations.

| Tip Number | Factor to Consider | Description | Impact on Efficiency |

|---|---|---|---|

| 1 | Material Selection | Choose materials that withstand environmental conditions. | +15% |

| 2 | Load Capacity | Ensure the coupling can handle the maximum operational load. | +10% |

| 3 | Dampening Characteristics | Select couplings that reduce vibrations. | +5% |

| 4 | Alignment Tolerance | Evaluate how much misalignment the coupling can tolerate. | +8% |

| 5 | Type of Coupling | Determine the best type (flexible, rigid, etc.) for your application. | +20% |

| 6 | Size and Weight | Consider space and weight constraints in the design. | +3% |

| 7 | Operating Temperature | Ensure the coupling performs well under intended temperatures. | +4% |

| 8 | Maintenance Needs | Select couplings with low maintenance needs to save costs. | +6% |

| 9 | Cost-Effectiveness | Weigh long-term savings against initial costs. | +5% |

| 10 | Supplier Reliability | Choose suppliers known for quality and support. | +2% |

When selecting a hub coupling, avoiding common mistakes is crucial to ensuring optimal performance and efficiency. One frequent error is neglecting to consider the torque requirements of the application. It's vital to match the coupling with the specific torque to prevent premature wear or failure. Additionally, failing to evaluate the alignment of the shafts can lead to increased vibration and noise, which ultimately affects operational efficiency. Proper alignment ensures that the coupling functions smoothly, extending its lifespan and maintaining productivity.

Another mistake to avoid is overlooking the material selection for the coupling. Different applications require specific materials to withstand environmental conditions, such as temperature fluctuations, moisture, or corrosive substances. Choosing the wrong material can result in coupling degradation and compromise overall system performance. Furthermore, not factoring in the coupling's maintenance requirements can lead to unexpected downtimes. Regular inspections and maintenance are essential to keep the hub coupling in optimal condition, preventing costly repairs or replacements in the long run.

Maintaining hub couplings is essential for maximizing their efficiency and prolonging their service life. According to a recent industry report by the Power Transmission Distributors Association (PTDA), regular maintenance can improve the efficiency of mechanical systems by up to 30%. Therefore, it’s crucial to implement a diligent maintenance routine.

One key tip is to conduct periodic inspections of the hub coupling for wear and misalignment. Misalignment can lead to increased operating temperatures and reduced efficiency. A study published in the Mechanical Systems and Signal Processing journal revealed that even minor misalignments could decrease efficiency by as much as 15%. Additionally, applying the correct lubricant at regular intervals not only minimizes friction but also helps to prevent premature wear and failures.

Another important aspect is to monitor operating conditions. Maintaining the recommended temperature and load specifications is vital, as extreme conditions can severely affect performance. The International Organization for Standardization (ISO) suggests adhering to predefined operating parameters, which are often outlined in the manufacturer’s guidelines. By staying proactive with these maintenance tips, you can significantly boost the efficiency of your hub couplings and ensure their optimal performance.

When it comes to choosing the right hub coupling, real-world examples shed light on the significant impact these components have on operational efficiency. For instance, in an industrial setting, a manufacturing plant implemented a specific hub coupling that reduced energy consumption by 30%. This coupling played a pivotal role in optimizing machinery performance, showcasing how the right choice can lead to substantial cost savings and improved workflow.

To ensure you make the best selection, consider these essential tips: First, assess the torque capacity required for your application and choose a coupling that meets or exceeds these specifications. Additionally, factor in the alignment characteristics of your system; a misaligned coupling can lead to premature wear and tear. Lastly, evaluate the material composition of the coupling to ensure it withstands environmental conditions specific to your industry. Incorporating these tips can lead to better performance and durability, much like how effective implementations in healthcare technology have transformed patient care and streamlined operations for providers.