In the construction and plumbing industries, the selection of pipe straps is critical for ensuring optimal load capacity and structural integrity. According to a report by the American Society of Mechanical Engineers (ASME), improper fastening techniques can lead to a significant increase in pipe system failures, which can account for up to 30% of maintenance costs in industrial applications. Pipe straps, which are essential components for securing piping systems, must be selected based on various factors including material type, load requirements, and environmental conditions. The American National Standards Institute (ANSI) emphasizes that appropriate pipe strap specifications are crucial for achieving compliance with safety regulations and preventing catastrophic failures. Therefore, understanding the nuances of choosing the right pipe straps is vital for engineers and contractors aiming to enhance the reliability and longevity of their piping systems.

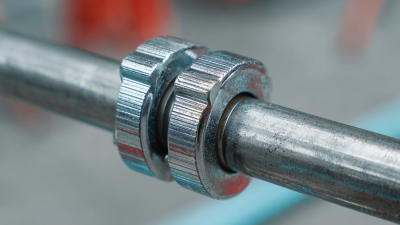

When it comes to selecting pipe straps, understanding the various types available is crucial to ensure both optimal load capacity and structural integrity. Generally, pipe straps can be categorized into two main types: standard pipe straps and adjustable pipe straps. Standard pipe straps are designed for fixed installations where the pipe size is constant, providing a straightforward solution for securing pipes in place. These straps are typically made from materials like stainless steel or plastic, offering durability and resistance to corrosion in diverse environments.

On the other hand, adjustable pipe straps offer flexibility for applications where pipes may vary in size or require repositioning. These straps often feature a sliding mechanism that allows for quick adjustments, making them ideal for temporary installations or settings where future modifications are anticipated. Understanding the specific requirements of your project, including factors such as pipe weight, environmental conditions, and potential shifts in layout, is essential in choosing the right type of pipe strap to ensure safety and longevity. By considering these aspects, you can effectively select the appropriate pipe strap type that aligns with your structural needs.

When selecting pipe straps, the foremost consideration should be the load capacity requirements dictated by the specific application. Pipe straps are designed to support piping systems, ensuring that they remain secure and stable under various conditions. Evaluating the anticipated loads—such as the weight of the pipes, insulation, and the fluid they carry—is crucial. It is essential to consider both the static and dynamic loads, as fluctuations in pressure or temperature can significantly affect the structural performance of the straps. Choosing straps with a sufficient margin above the calculated load capacity will further enhance reliability.

Additionally, the material of the pipe straps plays a vital role in their ability to withstand load requirements and environmental factors. Different materials offer varying strengths and resistance to corrosion, which is particularly important in industries involving chemicals or high moisture levels. For instance, stainless steel straps may be preferable in corrosive environments, while nylon alternatives may offer sufficient flexibility for lighter loads. Ultimately, a thorough assessment of both load requirements and material characteristics will ensure that the chosen pipe straps provide optimal performance and integrity for the piping system.

When selecting pipe straps, material choice plays a critical role in ensuring durability and strength. Different materials offer varying levels of resistance to environmental factors such as corrosion, temperature fluctuations, and mechanical stress. For instance, stainless steel is often favored for its remarkable corrosion resistance and overall strength, making it suitable for industrial environments where exposure to moisture and chemicals is prevalent. Meanwhile, nylon straps are lightweight and flexible, providing a non-corrosive alternative that is ideal for less demanding applications.

In addition to corrosion resistance, it's essential to consider the specific load requirements and the environment in which the straps will be used. For heavy-duty applications, materials like galvanized steel or high-density polyethylene can provide the necessary strength and impact resistance while maintaining structural integrity over time. Furthermore, incorporating features such as UV stabilization in polymer straps can enhance their longevity when exposed to sunlight and harsh weather conditions. By carefully evaluating these factors, one can effectively choose pipe straps that ensure optimal performance and reliability in various applications.

| Material Type | Load Capacity (lbs) | Corrosion Resistance | Temperature Resistance (°F) | Durability Rating |

|---|---|---|---|---|

| Stainless Steel | 1200 | High | -320 to 1500 | Excellent |

| Galvanized Steel | 1000 | Moderate | -10 to 800 | Good |

| PVC | 600 | Low | 32 to 140 | Fair |

| Aluminum | 700 | Moderate | -50 to 400 | Good |

| Composite | 800 | High | -100 to 300 | Excellent |

When installing pipe straps, ensuring proper alignment and installation is crucial for maintaining both load capacity and structural integrity. First and foremost, it is essential to assess the specific requirements of the piping system. This includes evaluating the size, material, and weight of the pipes to select appropriate strap types that can withstand the intended loads. Misalignment during installation can lead to increased stress on joints and potential failure, underscoring the need for precision in positioning.

The best practices for installation involve using the right tools and methods to secure the straps accurately. It is advisable to follow manufacturer guidelines and recommendations for spacing and placement to distribute loads effectively. Regular inspections of installed pipe straps are also vital, as they can help identify signs of wear or misalignment over time. By adhering to these practices, not only is optimal load capacity achieved, but the overall longevity and safety of the piping system can be significantly enhanced.

Periodic maintenance and inspection are crucial for ensuring the structural integrity of systems that rely heavily on pipe straps. Over time, environmental factors, load fluctuations, and material fatigue can lead to degradation, potentially compromising the support and alignment of piping systems. Regular inspections should focus on identifying signs of wear, such as corrosion, bending, or displacement of the straps. By implementing a structured maintenance schedule, engineers can detect early warning signs and address them before they escalate into costly repairs or safety hazards.

In addition to routine visual inspections, integrating advanced monitoring technologies can enhance the effectiveness of maintenance efforts. For instance, the use of strain gauges or ultrasonic testing can provide real-time data on the stress levels experienced by pipe straps, enabling more precise evaluations of their performance under various operational conditions. This proactive approach not only extends the life of the materials used but also ensures that the overall load capacity of the system remains intact, thus safeguarding the structural integrity and operational efficiency of the entire installation.