When it comes to efficient and organized airflow management, Ducting Clips play a crucial role in ensuring that your ducting system operates smoothly and effectively. These essential accessories are designed to secure ductwork in place, preventing any unwanted movement or sagging that could impede airflow. With a variety of options available on the market, selecting the right Ducting Clips is vital for achieving optimal performance in your heating, ventilation, and air conditioning (HVAC) systems.

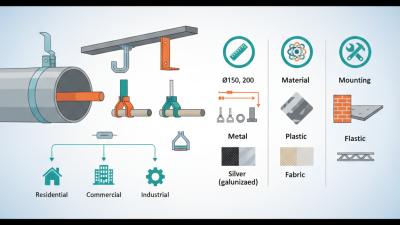

In this ultimate guide, we will explore the different types of Ducting Clips, their features, and how to choose the best options suitable for your specific applications. Whether you're working on a small residential project or a large commercial installation, understanding the various materials and designs will help you make informed decisions. Additionally, we will discuss key factors to consider, such as load capacity, installation ease, and environmental conditions, ensuring that your ducting system is both secure and efficient. With the right knowledge at your disposal, you can enhance the longevity and functionality of your ducting system significantly.

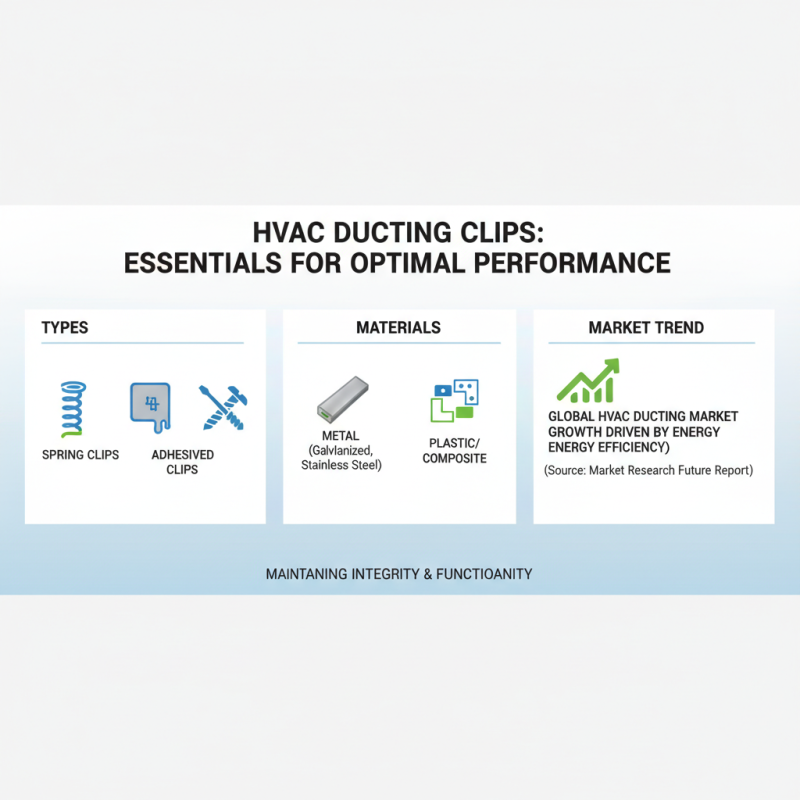

Ducting clips are essential components in various HVAC (Heating, Ventilation, and Air Conditioning) applications, playing a crucial role in maintaining the integrity and functionality of duct systems. Understanding the types and materials of ducting clips is vital for ensuring optimal performance and longevity. Common types of ducting clips include spring clips, adhesive clips, and screw-mounted clips, each designed to meet specific installation conditions and requirements. According to a recent industry report by Market Research Future, the global HVAC ducting market is projected to grow significantly, partly due to the rising demand for energy-efficient systems. This highlights the necessity of selecting the right ducting clips to support these systems effectively.

When it comes to materials, ducting clips are typically made from metals such as galvanized steel, stainless steel, or aluminum, each offering different levels of durability and resistance to environmental factors. For instance, galvanized steel is popular for its corrosion resistance and strength, making it suitable for both indoor and outdoor applications. In contrast, stainless steel provides enhanced durability, particularly in environments with high humidity or exposure to chemicals. A report from Transparency Market Research indicates that the durability of HVAC components, including ducting clips, can directly impact system performance and maintenance costs, underscoring the importance of choosing high-quality materials for long-term benefits.

When selecting ducting clips, it is essential to consider a few key factors to ensure they meet your specific requirements. Firstly, the material of the clips plays a significant role in their performance and durability. Stainless steel clips are known for their resistance to corrosion, making them ideal for environments where moisture is a concern. Meanwhile, plastic clips are lightweight and resistant to rust but may not withstand harsh conditions as well as their metal counterparts.

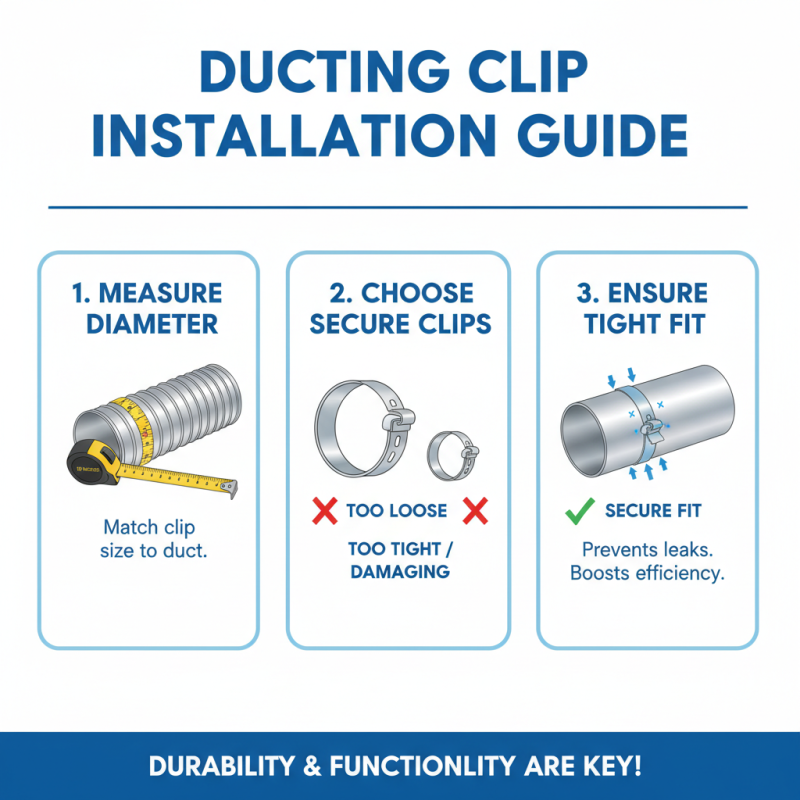

Another important consideration is the size and compatibility of the clips with your ducting system. Proper sizing ensures a secure fit, preventing leaks and improving efficiency. Measure both the duct diameter and the clip width to find the best match. Additionally, think about the thickness of the material you are working with, as this will influence the strength of the clip needed.

Tips: Always consider the installation surface when choosing ducting clips. For uneven surfaces, adjustable clips can provide a better grip. Furthermore, it's beneficial to have a variety of clip sizes on hand for different projects, as this flexibility can save you time and trouble during installations.

Ducting clips are essential components in numerous industries, serving a variety of functions from securing air ducts in HVAC systems to organizing wires and cables in telecommunications. In manufacturing, these clips ensure that ventilation systems operate efficiently, preventing leaks that could lead to energy losses or equipment failures. In construction, they are crucial for maintaining the structural integrity of ducting systems, ensuring that installations are reliable and compliant with safety standards.

When applying ducting clips in these settings, it's vital to choose the right type for your specific needs. For instance, in plumbing applications, robust clips that can withstand moisture and temperature fluctuations are necessary. Similarly, in electrical installations, clips designed to support heavier cables without sagging are preferred.

**Tip:** Always consider the material and size of the clips based on the environment they will be used in to maximize their effectiveness. Additionally, ensure that the clips provide easy access for any future maintenance work.

In the automotive industry, ducting clips play a pivotal role in securing hoses and ducts, contributing to the overall performance and safety of vehicles. Choosing the right clips can help reduce vibrations and noises, enhancing the comfort of the ride.

**Tip:** Utilize clips that are resistant to extreme temperatures and harsh chemicals often found in automotive environments to prolong their lifespan and ensure reliable performance.

When it comes to effectively using ducting clips, proper installation is crucial for ensuring durability and functionality. First, measure the diameter of the ducting you are using, as this will help you select clips that fit securely without damaging the ducts. A tight fit can prevent air leaks and maintain efficiency, which is essential for any ducting system.

Tip 1: Always clean the surface where the clips will be installed. Dust or grease can prevent a solid grip, leading to potential failure over time. Use a suitable cleaner to ensure that both the duct and the mounting surface are dry and free from debris before securing the clips in place.

Tip 2: When installing, space the clips evenly along the ducting. A good rule of thumb is to place clips every 3 to 4 feet, but this may vary based on the size and weight of the ductwork. This helps distribute weight evenly and reduces stress on the ducting system, ensuring that it remains securely in place.

Lastly, consider using a drill with appropriate-sized screws for installation. Pre-drilling holes can make the process easier and help avoid cracking or damaging the mounting surface. Take your time to ensure that each clip is perfectly aligned, as this will greatly enhance the overall performance and longevity of the ducting system.

Regular maintenance and inspection of ducting clips are essential for ensuring their longevity and optimal performance in HVAC systems. According to a report by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), improper installation and neglect can lead to a significant reduction in system efficiency, with reports stating energy losses can increase by up to 30% due to loose or damaged ducting attachments. Thus, routine checks for signs of wear, such as corrosion or stress fractures, should be part of a standard maintenance protocol.

In addition to inspections, proper cleaning of ducting clips is crucial. Dust and debris can accumulate, leading to potential blockages or reduced airflow. A study published in the Journal of HVAC Research highlighted that regular cleaning can enhance airflow by up to 15%, further substantiating the importance of maintaining these components. Maintaining a recommended schedule for inspections and cleaning not only extends the life of ducting clips but also contributes to a more energy-efficient system, ultimately reducing operational costs and ensuring consistent indoor air quality.

| Clip Type | Material | Diameter Range (inches) | Application | Maintenance Tips |

|---|---|---|---|---|

| Standard Duct Clip | Metal | 4 - 10 | HVAC Systems | Inspect regularly for rust |

| Plastic Duct Clip | Plastic | 3 - 12 | Ventilation | Keep away from direct sunlight |

| Heavy Duty Clip | Galvanized Steel | 5 - 14 | Industrial Applications | Check fastening regularly |

| Quick Release Clip | Aluminum | 4 - 10 | Rapid Installations | Ensure clips are clean before use |