Ducting Clips play a crucial role in various installation processes, ensuring that ducting systems are secure, organized, and efficient. According to industry expert John Smith, a leading authority in HVAC solutions, “Choosing the right Ducting Clips is essential for the longevity and performance of your duct systems." These clips are designed to hold ducts in place and prevent any unnecessary wear and tear, which can lead to inefficiencies and potential damage.

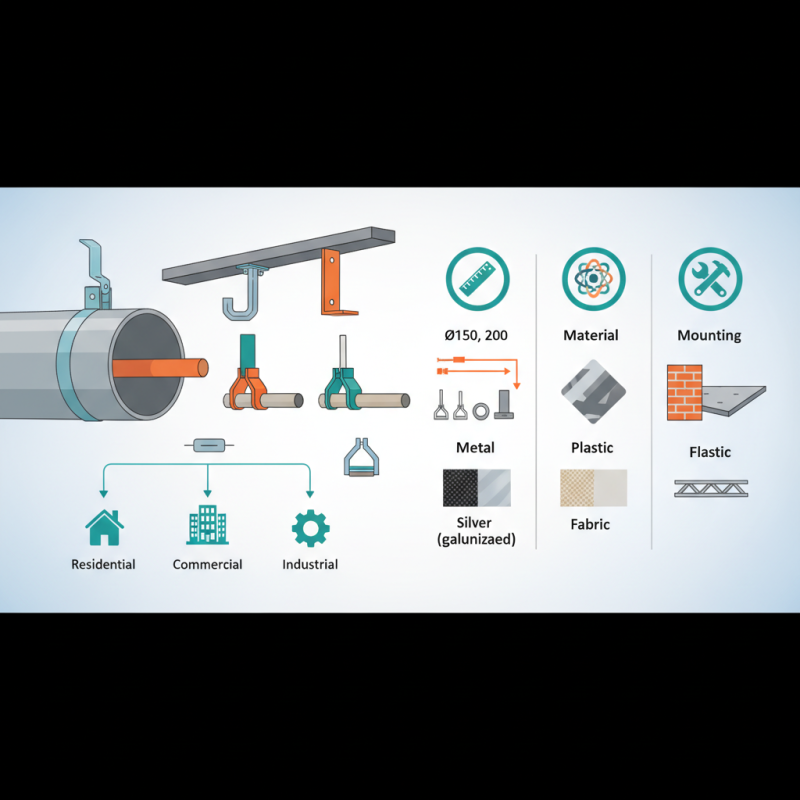

When it comes to selecting the appropriate Ducting Clips for your specific needs, it’s important to consider factors such as size, material, and application. Different environments may require different types of clips, whether for residential, commercial, or industrial settings. Understanding these variables will not only save time and effort during installation but also contribute to the overall effectiveness of your ductwork.

In this article, we will explore what Ducting Clips are, their various types, and offer guidance on making an informed choice that meets your requirements. Whether you're a seasoned professional or a DIY enthusiast, having the right information at your fingertips will pave the way for successful installation and optimal performance.

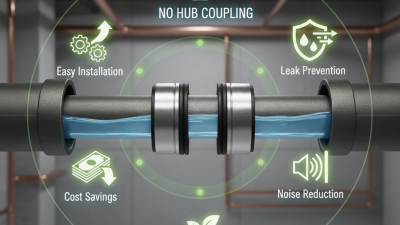

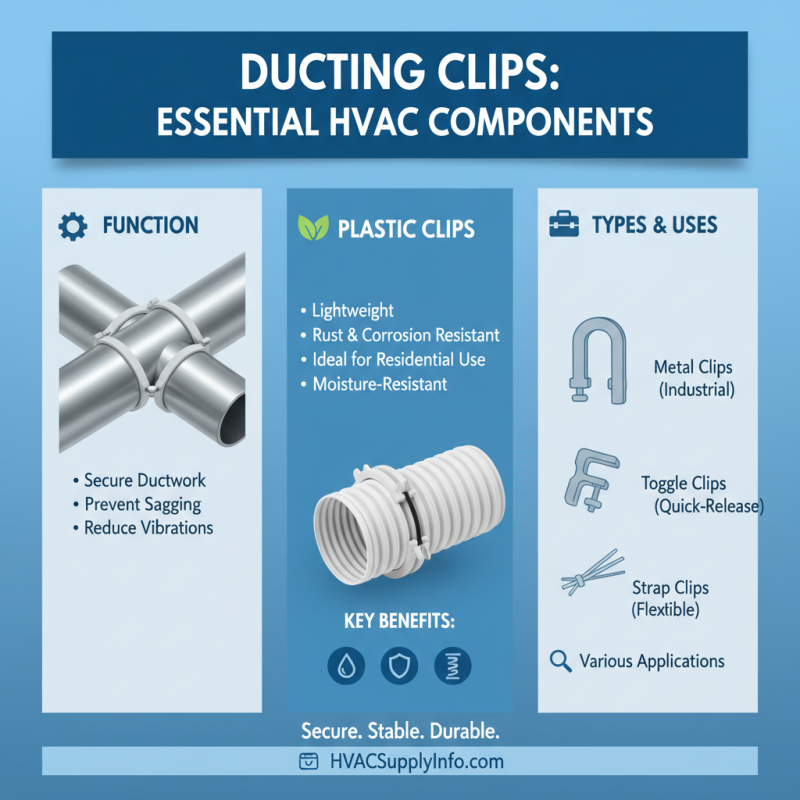

Ducting clips are essential hardware components designed to secure ductwork in various HVAC systems. These clips serve multiple purposes, primarily stabilizing ducts, providing a neat installation, and ensuring efficient airflow. By effectively holding ducting materials in place, they prevent sagging and misalignment, which can lead to air leaks and decreased system efficiency. Whether for residential or commercial applications, ducting clips are crucial for maintaining optimal indoor air quality and energy efficiency.

When choosing the right ducting clips for your needs, several factors should be considered. First, assess the size and type of ducting material you are using, as clips come in various sizes to accommodate different dimensions. Additionally, consider the material of the clips themselves; options range from plastic to metal, each offering different levels of durability and resistance to environmental factors. Finally, evaluate the installation method, as some clips may require tools while others can be easily installed by hand. By selecting appropriate ducting clips, you can ensure a secure and efficient ductwork setup tailored to your specific requirements.

| Type of Ducting Clip | Material | Size Compatibility | Weight Capacity | Typical Use |

|---|---|---|---|---|

| Plastic Clips | Polypropylene | 3" - 6" | Up to 5 lbs | Residential HVAC |

| Metal Clips | Galvanized Steel | 4" - 8" | Up to 20 lbs | Commercial HVAC |

| Heavy-Duty Clips | Stainless Steel | 6" - 12" | Up to 50 lbs | Industrial Applications |

| Adjustable Clips | Nylon | 3" - 10" | Up to 15 lbs | Flexible Installations |

Ducting clips are essential components used to secure ductwork in various HVAC and ventilation systems. There are several types of ducting clips available, each serving specific applications. For instance, plastic clips are lightweight and ideal for residential ducting, as they provide ample support while being resistant to rust and corrosion. These clips are particularly useful in environments where moisture may be a concern. Moreover, they can help in minimizing vibrations and ensuring ducts maintain their position without sagging.

On the other hand, metal ducting clips are preferred for industrial applications due to their strength and longevity. They are capable of handling heavier ducting materials and can endure higher temperatures. These clips are often used in commercial HVAC systems, where the ductwork needs to be securely fastened to withstand the rigors of a larger-scale operation. Additionally, adjustable clips can accommodate different duct sizes, making them versatile for various setups. Understanding the types and applications of ducting clips can significantly affect the efficiency and reliability of an HVAC or ventilation system.

When selecting ducting clips, there are several key factors to consider to ensure you make the right choice for your needs. First, the material of the clips is crucial; you should opt for clips made from high-quality materials that can withstand the environmental conditions they will be subjected to. For instance, according to a report by the HVAC Industry Association, stainless steel clips are noted for their durability and resistance to corrosion, making them ideal for both indoor and outdoor applications.

Another important consideration is the size and compatibility of the clips with the ducting system you are using. It is essential to measure the diameter of your ducting and select clips that provide a snug fit without being overly tight. According to industry standards, a properly fitted clip can enhance performance by reducing air leaks by up to 15%, which can lead to significant energy savings.

**Tips:** When in doubt about the clip size, it’s advisable to choose adjustable clips that can accommodate varying duct sizes. Additionally, always consider the application environment—whether in high heat, moisture, or corrosive surroundings—when selecting materials to ensure longevity and performance.

Finally, consider the installation process of the ducting clips. Some clips are designed for quick and easy installation without special tools, which can save you time and effort. Depending on the complexity of your ducting system, opting for user-friendly options can streamline the installation while ensuring effective duct management.

Proper installation of ducting clips is essential for ensuring the efficiency and durability of ductwork systems. According to a report by the Air Conditioning Contractors of America (ACCA), improperly secured ducting can lead to air leaks, resulting in up to 30% loss in energy efficiency. Therefore, selecting the right clips and installing them correctly can significantly enhance the performance of HVAC systems.

When installing ducting clips, the first step is to assess the specific requirements of your ducting type. Clips should match the diameter and material of the ductwork, ensuring a snug fit that prevents movement and vibration. Proper placement is also crucial; clips should be spaced evenly along the duct, typically every 3-4 feet for round ducts and closer for larger systems. Additionally, it is important to avoid overtightening clips, which can damage the ducting material. A study published in the Journal of HVAC Research indicated that adequate clip installation can improve air flow by up to 15%, underscoring the importance of attention to detail in this aspect.

Moreover, utilizing high-quality materials for ducting clips can ensure longevity and reliability. The National Institute of Standard and Technology (NIST) recommends clips that are resistant to corrosion, particularly in moist environments, to prevent deterioration over time. By following these guidelines, professionals and DIY enthusiasts alike can optimize their ductwork systems, leading to improved air quality and energy savings.

Maintaining ducting clips is essential for ensuring their durability and effectiveness in various applications. Proper care can significantly enhance their lifespan and performance. One important maintenance tip is to regularly inspect the clips for signs of wear or damage. Look for cracks, rust, or any deformation that may affect their holding ability. If any defects are found, it’s best to replace the clips immediately to prevent system failure.

Another tip is to ensure that the clips are properly tightened without overdoing it. Over-tightening can lead to stress and damage, while loose clips may cause vibrations and instability. Periodically check the tightness and adjust as necessary to maintain optimal performance. Additionally, keeping the area around the ducting clips clean and free of debris will help prevent corrosion and ensure a secure fit.

Lastly, consider the environment in which the clips are installed. Extreme temperatures, humidity, or exposure to chemicals can all affect their longevity. If operating in harsh conditions, look for materials that offer better resistance to these factors. By following these tips, ducting clips will not only function more effectively but will also last longer, making them a reliable component in any ducting system.