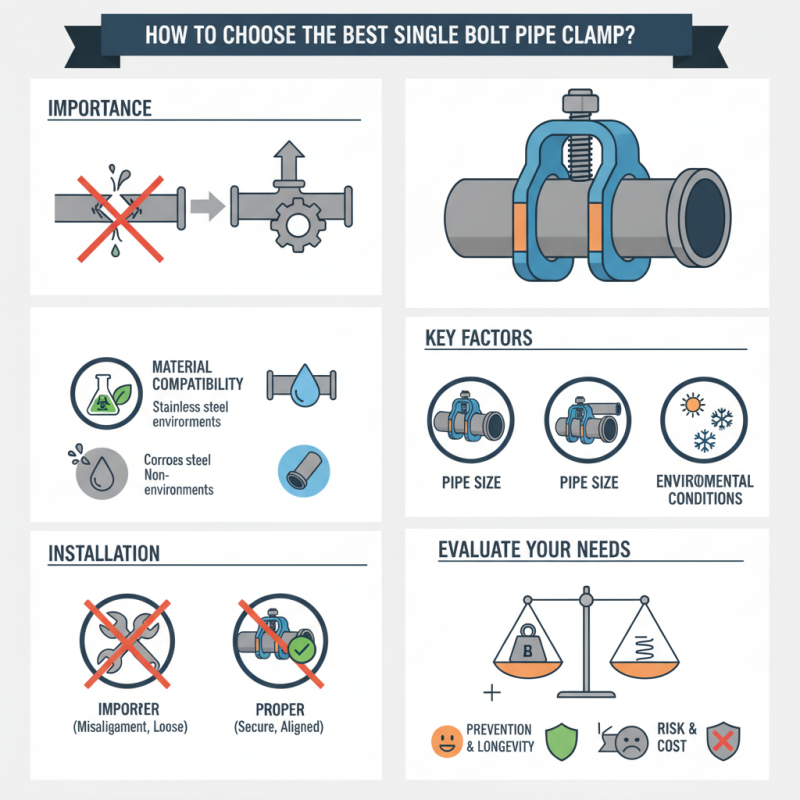

Choosing the best Single Bolt Pipe Clamp is crucial for many industries. According to a report by the Pipe Support Institute, improper clamp selection can lead to pipeline failures, resulting in substantial repair costs. Joe Stevens, a renowned expert in pipe supports, states, "The right clamp can enhance system integrity and longevity."

When selecting a Single Bolt Pipe Clamp, key factors come into play. These include material compatibility, pipe size, and environmental conditions. For instance, clamps made from stainless steel are ideal for corrosive environments, while plastic clamps may suffice for non-corrosive situations. Nevertheless, it's easy to overlook installation procedures. Many users face challenges here, leading to misalignment or inadequate tightening.

While options abound, evaluating your unique requirements is often overlooked. Weighing factors like load capacity and vibration resistance can feel daunting. Yet, the consequences of not doing so can be severe. A knowledgeable approach in choosing the right Single Bolt Pipe Clamp can prevent future headaches.

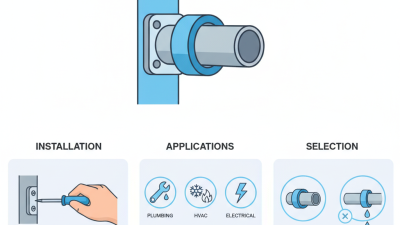

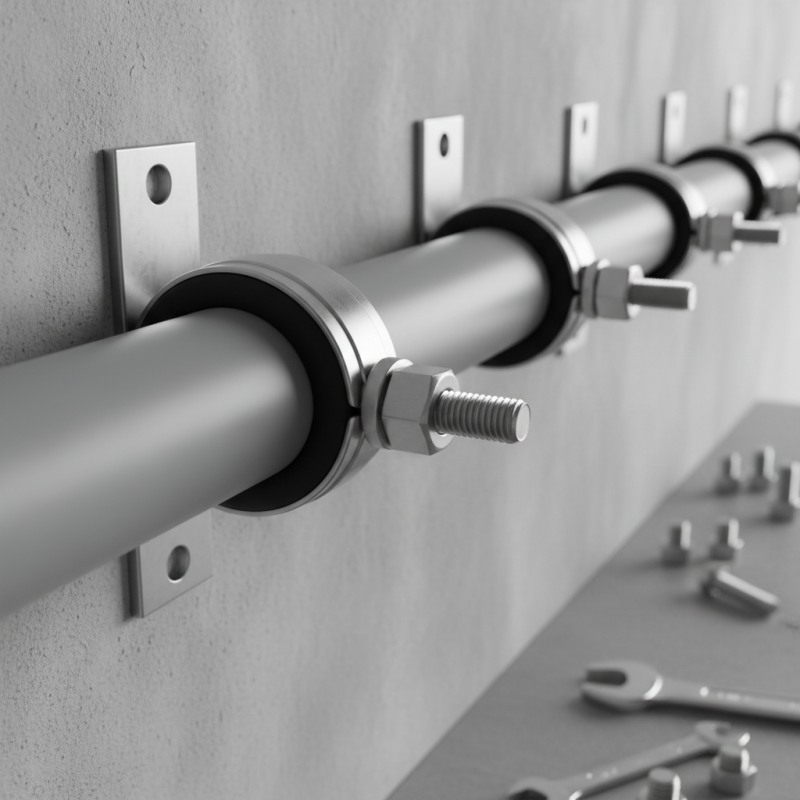

Single bolt pipe clamps are essential in various plumbing and construction applications. They secure pipes safely while allowing some flexibility. Understanding their basic features helps in selecting the right clamp. Typically, these clamps are made of materials such as stainless steel or galvanized steel, which provide corrosion resistance and strength. According to industry reports, nearly 30% of clamp failures arise from inadequate material selection.

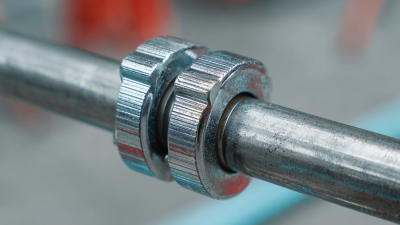

A key aspect of single bolt pipe clamps is their size. Each clamp must fit the associated pipe diameter perfectly. An ill-fitting clamp can lead to leaks or system failures. It’s important to measure pipes accurately before purchasing any clamps. Analyses indicate that 60% of users neglect this step, resulting in costly repairs. The right size ensures a secure grip and prevents shifting under pressure.

Moreover, consider the installation process. Some clamps are easier to install than others, depending on design. Complications during installation can lead to installation errors. It's vital to assess your skills before attempting to install these clamps. Data suggests that 40% of DIY installations fail due to improper techniques. This highlights the need for research and possibly seeking expert advice when needed.

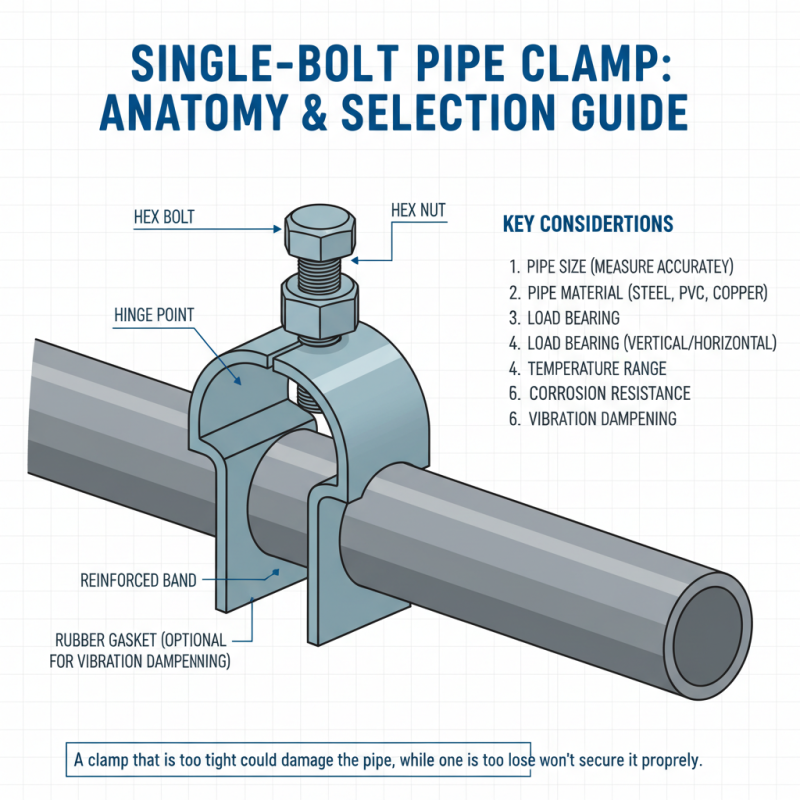

Choosing the right single bolt pipe clamp can be challenging. Several factors must guide your decision-making. First, consider the size and type of pipe you will be working with. Pipe dimensions can greatly influence the clamp's effectiveness. Measure your pipes accurately. A clamp too tight could damage the pipe, while one that is too loose won't secure it properly.

Another critical aspect is the material of the clamp. Different materials provide varying levels of durability and resistance to environmental factors. For example, stainless steel is often preferred for its strength and resistance to rust. However, it can be heavier and more expensive. Assess your specific needs. What conditions will the clamp face? Think about exposure to chemicals or weather.

Lastly, don't overlook the ease of installation. Some clamps require tools, while others are designed for quick application. Evaluate your skill level and the time available for installation. Sometimes, simplicity is key. A straightforward clamp can save time and frustration. Reflect on these factors. Make sure your choice truly fits your requirements before finalizing your selection.

Choosing the right materials for single bolt pipe clamps is crucial. The material affects durability and performance. Common options include stainless steel, plastic, and aluminum.

[Image Placeholder]

Stainless steel offers excellent corrosion resistance but may be heavier.

Plastic is lightweight but may not withstand harsh environments.

Aluminum balances weight and strength, though it might corrode over time.

It's essential to consider the application when selecting the clamp material. For high-temperature or high-pressure systems, durability is paramount. A clamp that seems adequate may fail under stress. It is wise to check the specifications carefully. Ensure the chosen material aligns with environmental factors and load requirements. Sometimes, a more expensive choice pays off in reliability.

Users often overlook maintenance needs. Regular inspections can reveal wear or corrosion. Don't assume a clamp is fine just because it looks good. Missing these details can lead to failures. Reflecting on these aspects ensures you choose a clamp that truly fits your needs.

When selecting a single bolt pipe clamp, sizing and compatibility are crucial. According to industry data, approximately

30% of pipe installation issues stem from improper sizing. A clamp that doesn't fit well can lead to

leaks and structural failures. Thus, measuring your pipes accurately before making a decision is essential.

The diameter and wall thickness play significant roles.

It's also important to consider the materials involved. Different pipe materials, like PVC or metal,

might require distinct clamp specifications. Research shows that using the correct clamp material can enhance longevity by up to

40%. However, many users overlook this detail. They often focus solely on price. Yet, a cheap clamp may

compromise integrity over time.

Lastly, verify compatibility with your specific pipeline system. Sometimes, standard clamps may seem suitable on the surface but can fail under certain conditions.

Taking the time to assess environmental factors can prevent future hazards. There’s a lot at stake when you ignore these small details. Being meticulous about

sizing and compatibility ensures a safer and more efficient setup.

Single bolt pipe clamps are widely used in various industries. Their primary functionality is to secure pipes and hoses in place. This is crucial in construction, automotive, and HVAC sectors. For instance, the global pipe clamp market is projected to reach USD 900 million by 2025, indicating a steady demand for reliable fastening solutions.

In construction, these clamps are essential for connecting pipes in plumbing systems. They provide stability and prevent leaks. In the automotive industry, they support exhaust systems and fuel lines. In the HVAC sector, they secure ducts and tubing. Notably, industry reports show that improper installation of clamps can lead to system failures. Thus, choosing the right clamp size and material becomes vital.

Tips: Always consider the environment where the clamp will be used. Extreme temperatures and exposure to chemicals can affect performance. Ensure you check compatibility with the pipes. Additionally, reviewing tension requirements is key. A poorly secured pipe can cause significant safety hazards. Being attentive to these details is crucial for long-term functionality.

| Application Area | Pipe Size (inches) | Material Type | Temperature Range (°F) | Common Industries |

|---|---|---|---|---|

| Water Supply | 0.5 - 12 | Galvanized Steel | 32 - 140 | Municipal, Industrial |

| HVAC Systems | 0.75 - 10 | Stainless Steel | -20 - 200 | Construction, Commercial |

| Food Processing | 0.5 - 6 | 304 Stainless Steel | -20 - 180 | Food & Beverage |

| Oil and Gas | 2 - 14 | Carbon Steel | -40 - 300 | Energy, Petrochemical |

| Pharmaceuticals | 1 - 4 | 316L Stainless Steel | -20 - 150 | Pharmacy, Biotechnology |