When embarking on a project that requires the use of Pvc Clamps, it is crucial to make an informed decision to ensure both efficiency and safety. According to a report from MarketsandMarkets, the global pipe clamps market is expected to grow from USD 1.2 billion in 2021 to USD 1.9 billion by 2026, indicating a rising demand for effective clamping solutions in various industries. Selecting the right Pvc Clamps not only affects the durability and reliability of installations but also influences overall project costs and timelines. With the increasing diversification of applications ranging from plumbing to construction, understanding the specific requirements of your project is essential. This guide will provide insights into the factors to consider when choosing Pvc Clamps, helping you to optimize performance and meet the unique demands of your undertaking.

When it comes to selecting the right PVC clamps for your project, understanding the different types available in the market is crucial. PVC (polyvinyl chloride) is widely utilized across various industries, which directly influences the demand for specialized PVC products, including clamps. As the global PVC market is projected to grow from $678.9 billion in 2023 to $963.2 billion by 2031, with an annual growth rate of 4.53%, the variety of available PVC clamps has expanded significantly.

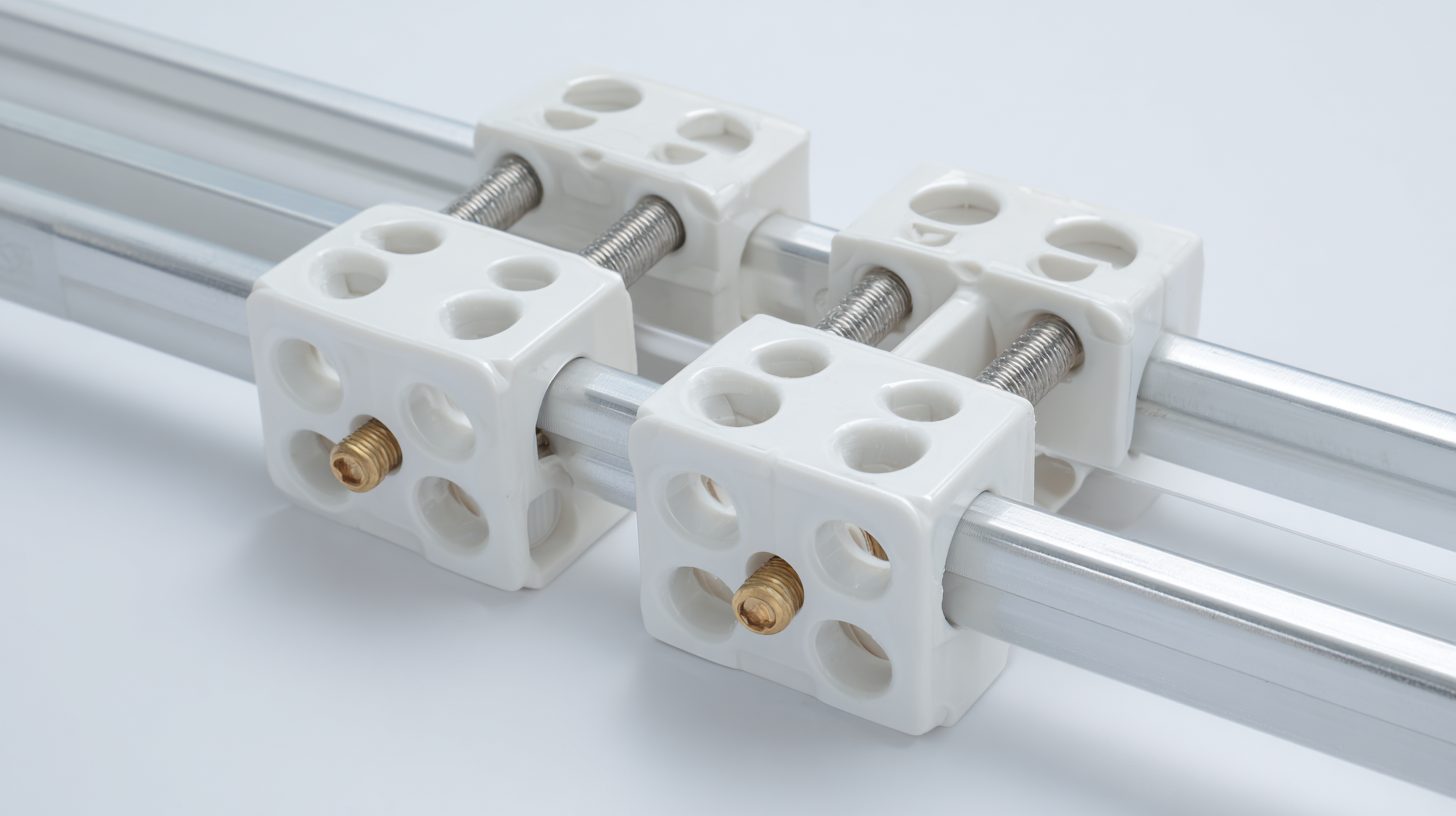

Among the various types of PVC clamps, they can be categorized based on their size, design, and intended application. For instance, some clamps are designed for heavy-duty applications, while others cater to light-duty needs. Additionally, the introduction of flexible and rigid options allows users to select clamps that best suit their specific project requirements. As the construction industry and other sectors continue to evolve, particularly with the increasing application of PVC flooring predicted to thrive in domestic markets, having the right PVC clamps can ensure durability and efficiency in project execution. Thus, choosing the appropriate type can greatly affect the success of your project.

When selecting the right PVC clamps for your project needs, several key factors should be considered to ensure optimal performance and durability. One critical aspect is the size of the clamp, which must match the diameter of the PVC pipe you are working with. According to industry reports, properly sized clamps can prevent leaks and enhance the lifetime of your piping system, as mismatched sizes can lead to pressure loss or damage.

Another significant factor is the material composition of the clamps. PVC clamps are commonly made from various plastics or metals, with high-quality PVC offering superior resistance to corrosion and weathering. A survey indicated that projects utilizing high-grade materials experience a 35% increase in longevity compared to those that do not. Additionally, consider the environmental conditions—if your project is exposed to extreme temperatures or chemicals, selecting clamps designed specifically for those environments is essential for maintaining structural integrity.

Lastly, the clamp's design can greatly affect ease of installation and maintenance. Features such as quick-release mechanisms or adjustable sizes can save time and effort during assembly. Industry analysis suggests that projects using user-friendly designs report 50% faster setup times, allowing for greater efficiency in project completion. Keeping these factors in mind will aid in choosing the most suitable PVC clamps to meet your specific project needs.

When selecting PVC clamps for your project, it's crucial to assess their compatibility with the specific pipe sizes and materials. Notably, the emerging bio-based medical-grade PVC compounds exhibit properties that are comparable to conventional PVC. These innovative materials could be considered when matching clamps with pipes, especially in medical or high-stakes applications where material integrity is paramount. Ensuring that the clamps can accommodate variations in dimensions and material properties will enhance the overall effectiveness and longevity of your project.

Furthermore, with the pipe market increasingly turning to new materials to address aging water infrastructure, compatibility is more important than ever. Selecting PVC clamps that are suitable for both traditional PVC and newer plastic materials can ensure a seamless installation and prevent issues like leaks and bursts. As technology evolves, so does the need for reliable components that can adapt to various applications, making it essential to carefully evaluate the specifications of both the clamps and the pipes they will support.

When selecting PVC clamps for your project, evaluating the load capacity and durability is crucial for ensuring long-term effectiveness. Just as a recent study highlighted the importance of bond durability in restorative systems, similar principles apply to PVC clamps in construction and repair applications. The load capacity determines how much weight a clamp can safely support, and understanding this will prevent failures that could compromise your project.

Tips: Always check the manufacturer's specifications for weight limits and consider the environmental conditions the clamps will face. For outdoor projects, UV resistance and exposure to moisture are essential factors for prolonging the life of your clamps.

Durability also involves the materials used in manufacturing. Clamps made from high-quality PVC will generally offer better resistance to cracking and wear over time. Conducting a side-by-side comparison of products can illuminate differences in construction quality and overall performance. Additionally, consider the clamp design, as certain styles may provide better stability under specific conditions.

Tips: Look for clamps that offer a warranty, as this can be an indicator of the manufacturer's confidence in their durability. Always opt for clamps from reputable brands to ensure you get the best quality for your needs.

The following chart illustrates the load capacity (in pounds) and durability (in hours under stress) of various PVC clamps suitable for long-term use.

When selecting PVC clamps for your project, understanding how budget constraints affect your choices is crucial. With various options available, the price can often be a determining factor in quality and durability. A recent industry report noted that investing in quality tools, even at a higher price point, typically results in better long-term performance. In fact, opting for mid-range clamps can ensure you avoid frequent replacements, leading to cost savings over time.

When budgeting for PVC clamps, it's essential to consider the project's specific needs while weighing durability against the price. For general use, clamps priced between $10 to $30 often offer reliable performance without breaking the bank. However, for professionals or heavy-duty tasks, investing in premium models ranging from $40 to $100 may provide additional functionality and longevity.

**Tips:**

1. Always review customer feedback and professional recommendations before making a purchase to find the best balance between cost and quality.

2. Look for seasonal sales or bulk purchase options, as they can significantly reduce costs while allowing for a higher quality selection.

3. Keep an eye on warranties and return policies; these often indicate a manufacturer’s confidence in their product and can provide peace of mind in your investment.

| Type of PVC Clamp | Size (inches) | Material | Price ($) | Application |

|---|---|---|---|---|

| Standard PVC Clamp | 1 | PVC | 2.50 | Pipe support |

| Heavy-Duty PVC Clamp | 2 | Reinforced PVC | 5.00 | High pressure systems |

| Adjustable PVC Clamp | 1.5 | PVC | 3.50 | Variable applications |

| Tension PVC Clamp | 3 | PVC | 7.00 | Support under tension |

| Quick Release PVC Clamp | 2.5 | PVC | 4.00 | Rapid installation |