When embarking on any construction or engineering project, the selection of the appropriate components is crucial to ensuring both safety and efficiency. One such component that often plays a vital role in piping systems is the Pipe Clevis. Renowned industry expert, John Smith, a mechanical engineer with over two decades of experience in the field, states, “Choosing the right Pipe Clevis can make the difference between a successful installation and a costly failure.” This underscores the importance of understanding the various types, sizes, and materials of Pipe Clevises available in the market.

In this guide, we will explore the key factors to consider when selecting a Pipe Clevis for your projects. From load requirements to environmental conditions, selecting the right Pipe Clevis involves careful evaluation of project specifications and operational demands. Remember, a properly chosen Pipe Clevis not only enhances the structural integrity of your piping system but also ensures compliance with safety standards. Whether you are a seasoned engineer or a newcomer to the field, this article will equip you with the knowledge necessary to make informed decisions regarding Pipe Clevis selection in 2025 and beyond.

A pipe clevis is an essential component in various mechanical applications, serving as a fastening device that connects a rod, hose, or pipe to a support structure. This U-shaped piece typically features a hole at the base that allows for the secure attachment of a bolt or pin, enabling the clevis to absorb loads and reduce vibrations. According to a report by the Global Industry Analysts, the market for fastening devices, including pipe clevises, is projected to grow significantly, driven by increasing infrastructure projects and machinery development in the construction and manufacturing sectors.

Understanding the functionality of pipe clevises is critical for their effective application in engineering projects. They are designed to provide flexibility within a system while maintaining strength and stability. The clevis design allows for angular movement, making it ideal for applications subjected to dynamic loads. A recent study by the American Society of Mechanical Engineers highlighted that the proper selection of clevis types based on load requirements can enhance the safety and durability of piping systems, reducing failure risks by up to 30%. This emphasizes the importance of not just opting for any clevis but ensuring it matches the specific dimensions and load criteria of the project at hand.

When selecting the right pipe clevis for your projects, several key factors must be considered to ensure optimal performance and reliability. First, it’s crucial to evaluate the load capacity of the clevis, ensuring it can handle the weight of the piping system it will support. This involves considering both the static and dynamic loads that may impact the clevis during operation. A thorough understanding of the specific applications and environmental factors, such as temperature fluctuations and exposure to chemicals, can significantly influence material selection and overall durability.

Another important consideration is the -sizing and compatibility of the pipe clevis with the existing infrastructure. Accurate measurements and alignment with the pipe dimensions are essential to guarantee a secure fit and installation. Additionally, the ease of installation and maintenance may vary with different designs; thus, selecting a clevis that allows for straightforward attachment and adjustments can save time and labor costs during the project lifecycle. Taking these factors into account will help ensure that the chosen pipe clevis meets both safety standards and project requirements effectively.

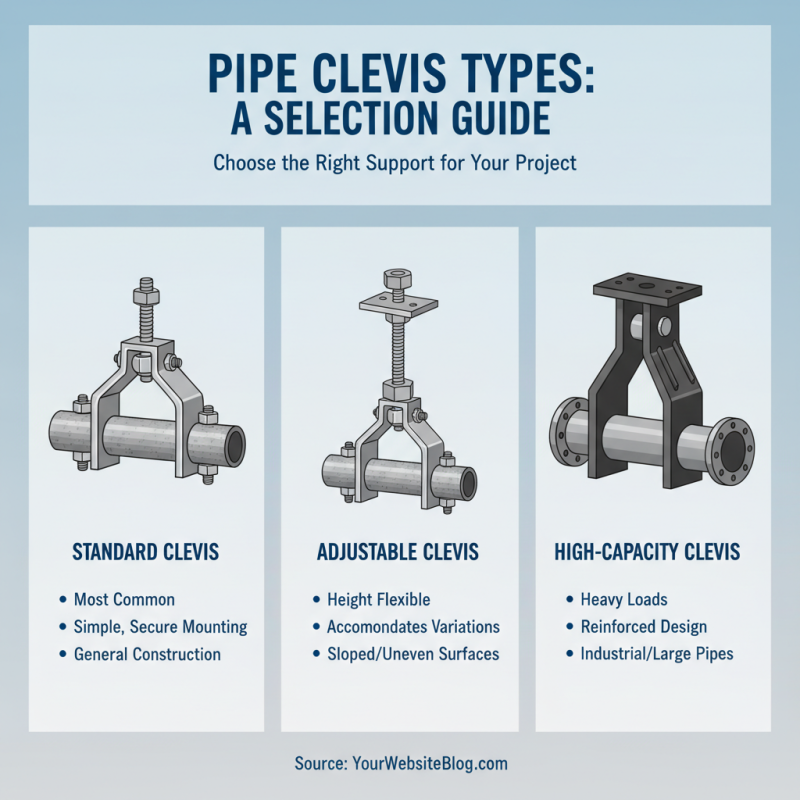

When selecting the right pipe clevis for your project, it's essential to understand the various types available and how they can best serve your specific needs. Generally, pipe clevises come in several configurations, such as standard, adjustable, and high-capacity clevises. The standard clevis is the most common, designed to provide secure mounting for pipes in straightforward applications. Its simplicity allows for easy installation, making it a preferred choice for many general construction projects.

Adjustable pipe clevises offer the versatility that is often necessary for more complex structures. These clevises can accommodate variations in pipe size and orientation, allowing for adjustments during installation for optimal alignment. This feature is particularly beneficial in applications where pipes may need to be repositioned due to space constraints or design changes. On the other hand, high-capacity clevises are designed to bear heavier loads, making them suitable for industrial applications or settings where enhanced strength and stability are paramount. Understanding these distinctions ensures that you select the most appropriate clevis for your specific application, enhancing both performance and safety.

When selecting the right pipe clevis for your projects, understanding the material choices available is crucial. Common materials include steel, stainless steel, and plastic, each with distinct pros and cons. Steel, for instance, offers exceptional strength and load-bearing capacity, making it suitable for heavy-duty applications. According to the American Institute of Steel Construction, steel can withstand extreme stresses, making it a top choice for construction and industrial projects. However, its susceptibility to corrosion limits its lifespan without appropriate coatings, especially in harsh environments.

On the other hand, stainless steel provides an excellent alternative by combining strength with corrosion resistance. Reports from the Stainless Steel Information Center reveal that stainless steel not only enhances longevity due to its inherent resistance to rust and corrosion but also maintains structural integrity even under varying temperatures. This makes it ideal for applications in food processing, chemical industries, and marine environments. However, it comes at a higher cost compared to regular steel, which may be a consideration for budget-conscious projects.

Plastic clevises, while less common, present a lightweight and cost-effective solution. Their resistance to chemical corrosion and lower weight makes them suitable for applications where weight is a critical factor. However, they typically lack the load-bearing capacity of metal alternatives and may not be suitable for high-stress environments. According to market analysis from the Plastics Industry Association, the ongoing innovations in plastic materials are paving the way for more robust applications, potentially expanding their use in future projects. Assessing these material choices' properties and limitations is essential in ensuring the right fit for your specific needs.

This bar chart illustrates the material strength (in MPa) of various pipe clevis options. Steel offers the highest strength, making it a reliable choice for heavy-duty applications, while plastic is suitable for lighter loads due to its lower strength. Consider the specific requirements of your project when choosing the material.

Proper installation and maintenance of pipe clevises are crucial for ensuring the longevity and reliability of piping systems. According to industry studies, improper installation can lead to issues such as misalignment, stress concentrations, and even complete system failures. To mitigate these risks, it is essential to follow the manufacturer's guidelines during installation, ensuring that the clevis is securely attached and appropriately sized for the specific application. The alignment should be double-checked to maintain optimal functionality, as even slight deviations can increase wear and tear and necessitate costly repairs.

Routine maintenance is equally important in maximizing the performance of pipe clevises. Reports indicate that regular inspections, preferably every six months, can help identify signs of wear, corrosion, or fatigue before they escalate into more significant problems. Lubrication of moving components and proper cleaning are also recommended to maintain optimal operational conditions. Studies in the field have shown that a well-maintained clevis can enhance the overall efficiency of a piping system by approximately 15%, contributing to a decrease in downtime and maintenance costs. By adhering to these guidelines, project managers can ensure that their piping systems operate smoothly and efficiently.