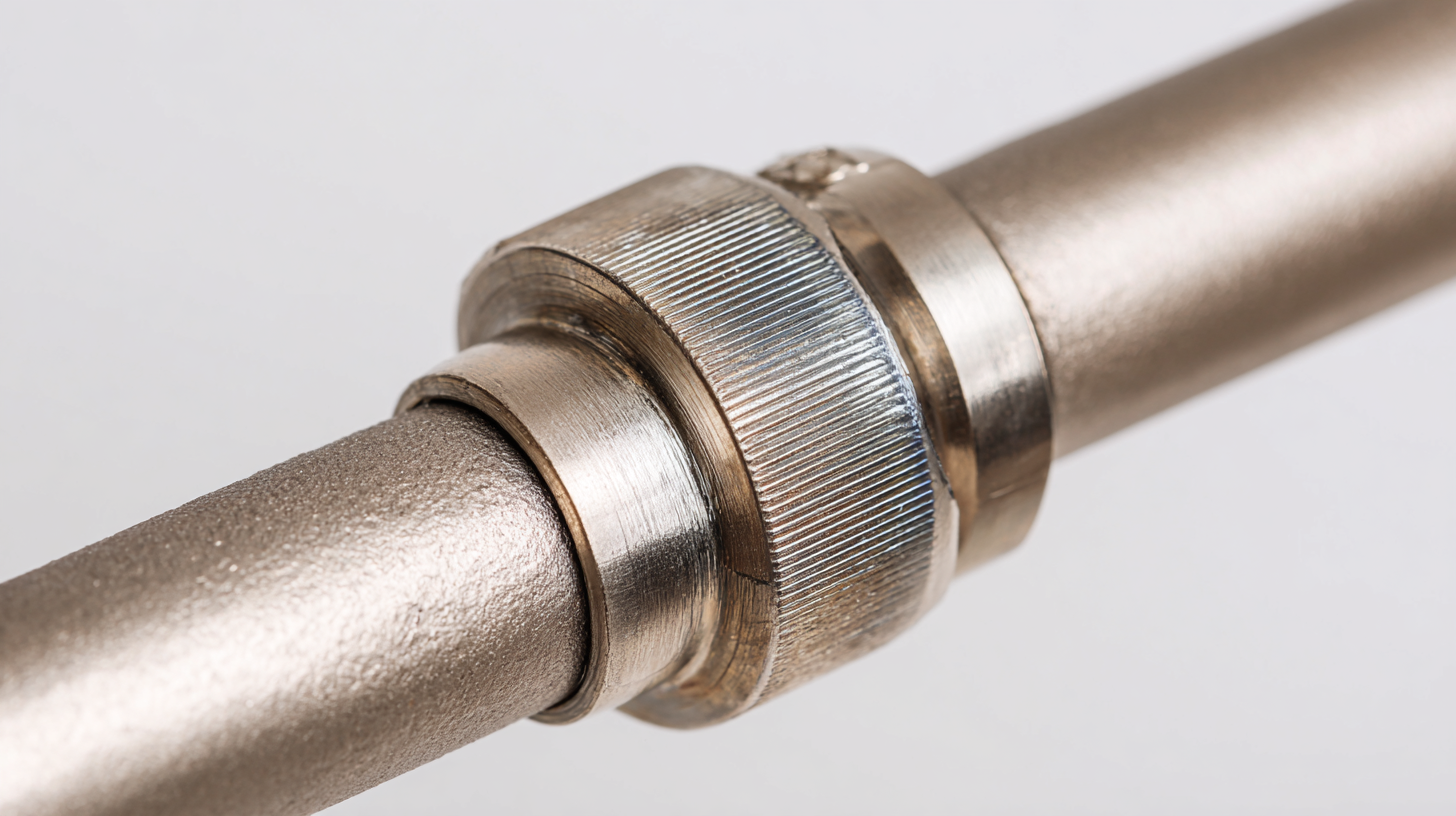

When it comes to plumbing systems, selecting the right components is crucial for ensuring optimal performance and durability. One such component that plays a significant role in plumbing installations is the No Hub Coupling. Designed to connect various piping materials securely and effectively, No Hub Couplings offer a range of advantages, including ease of installation and resistance to leakage.

When it comes to plumbing systems, selecting the right components is crucial for ensuring optimal performance and durability. One such component that plays a significant role in plumbing installations is the No Hub Coupling. Designed to connect various piping materials securely and effectively, No Hub Couplings offer a range of advantages, including ease of installation and resistance to leakage.

However, with so many options available on the market, choosing the right No Hub Coupling can be a daunting task. In this guide, we will explore key factors to consider when selecting a No Hub Coupling, including material compatibility, size, and application, ensuring that your plumbing projects run smoothly and efficiently. Let's dive into how to make an informed decision that will enhance the performance and longevity of your plumbing system.

No hub couplings are essential components in plumbing that ensure the stability and leak-proofing of pipe joints. Understanding their key features and benefits can significantly enhance your plumbing performance. These couplings are designed to connect pipes without the need for additional fittings, making them a versatile option for various installations. One of the primary advantages is their flexibility; they can accommodate slight misalignments, which is particularly beneficial in areas where pipes must navigate around obstacles.

When selecting a no hub coupling, consider the material used. Most couplings are made from durable materials such as cast iron or PVC, which offer different levels of resilience and corrosion resistance. The diameter of the coupling is also crucial; it must match your existing pipes to ensure a proper fit. Remember, investing in high-quality no hub couplings can save you time and money by reducing the chances of future leaks.

Tips: Always check the manufacturer's specifications for pressure ratings to ensure the coupling meets your system requirements. Additionally, when installing no hub couplings, ensure that the rubber gasket is properly seated to prevent any gaps that could lead to leaks. Regular inspections of your plumbing system can help identify worn couplings before they cause bigger issues.

When selecting the appropriate no hub coupling for your plumbing system, identifying the right size is crucial for ensuring optimal performance. According to the American Society of Plumbing Engineers (ASPE), selecting the correct coupling size can reduce the risk of leaks, improve water flow efficiency, and extend the lifespan of your plumbing infrastructure. A no hub coupling typically accommodates varying pipe sizes, but it is essential to carefully measure the diameter of your pipes to achieve a proper fit.

Industry reports suggest that a significant percentage of plumbing failures stem from improperly sized connections. For instance, a study by the National Plumbing Association found that nearly 30% of plumbing issues relate to incompatible fittings. By adhering to manufacturer specifications and utilizing a sizing chart, plumbers can choose couplings that match not just the pipe diameter, but also the material type, ensuring compatibility and reducing the likelihood of future complications. Additionally, adhering to local codes and regulations, which often include specific sizing requirements, can further guarantee the integrity of the plumbing system.

When selecting a no hub coupling, the choice of material plays a crucial role in ensuring optimal plumbing performance. PVC, cast iron, and other materials each offer unique advantages and disadvantages. According to industry reports, PVC is known for its lightweight and corrosion-resistant properties, making it an excellent choice for residential applications. Contrarily, cast iron couplings provide superior durability and strength, which is particularly beneficial in commercial settings where the plumbing systems are exposed to higher pressures.

Tip: Always consider the specific application and environment when choosing the material for your coupling. For instance, in areas prone to high humidity or chemical exposure, opting for PVC can significantly reduce the risk of corrosion and leakage. On the other hand, if noise reduction and sheer strength are priorities, particularly in large buildings, cast iron would be the ideal choice.

Moreover, it's essential to account for the long-term performance of the material. Reports indicate that while PVC may have a lower upfront cost, cast iron often provides a longer lifespan, potentially leading to reduced maintenance costs over time.

Tip: Evaluate the total cost of ownership when making your decision. Sometimes, investing in a more expensive but durable option like cast iron can save money and hassle in the long run.

When installing no hub couplings, ensuring a secure and leaky-free connection is paramount for optimal plumbing performance. One essential tip is to meticulously clean the pipe ends before installation. Any debris or dirt can compromise the seal and lead to leaks, so using a wire brush to scrub the surfaces ensures they are smooth and free of contaminants.

Another important aspect is to properly align the pipes before tightening the coupling. Misalignment can cause stress on the joints and may result in premature failure. To achieve perfect alignment, take your time and make necessary adjustments before applying torque to the coupling. Be sure to follow the manufacturer’s specifications for the recommended torque settings to avoid over-tightening, which can damage the coupling.

Lastly, always inspect the coupling after installation to verify that it is seated correctly. A quick visual check can reveal any gaps or irregularities that can arise during tightening. By paying attention to these details, you can secure a trustworthy and leak-proof connection that will serve your plumbing system well for years to come.

Maintaining no hub couplings is crucial for ensuring optimal performance in plumbing systems. According to a report by the Plumbing Manufacturers International (PMI), regular maintenance and inspections can extend the lifespan of no hub couplings by up to 30%. One of the key maintenance tips involves routinely checking for signs of wear and tear, such as corrosion or cracking, as these issues can compromise the integrity of the coupling. Schedule comprehensive inspections at least once a year to catch these problems early, especially in high-usage commercial environments.

In addition to visual inspections, it’s essential to ensure proper installation and torque specifications are followed. A study from the American Society of Plumbing Engineers (ASPE) emphasizes that improper installation can lead to leaks, resulting in costly repairs and water damage, which can be up to 20% of a building’s maintenance costs. Regular lubrication of the rubber gaskets and keeping them free from dirt and debris will also enhance their sealing capabilities. By following these maintenance tips, you can significantly improve the longevity and reliability of no hub couplings, contributing to the overall efficiency of your plumbing system.