When embarking on plumbing projects, one often overlooks the significance of pipe hanger clips, despite their critical role in maintaining the integrity and functionality of piping systems. According to a recent industry analysis by the Plumbing-Heating-Cooling Contractors Association (PHCC), improper installation of piping supports, including hanger clips, can lead to increased maintenance costs and even system failures, with potential damage costs exceeding $5,000 in severe cases. This highlights the necessity for selecting the right hanger clips that not only meet the mechanical load requirements but also ensure compliance with local building codes.

The market for pipe hangers and supports is projected to grow significantly, driven by an increasing demand for efficient plumbing systems in both residential and commercial structures. A recent report from Global Industry Analysts indicates that the rise in construction activities, particularly in the emerging markets, will bolster the demand for quality pipe hanger clips. With various materials, designs, and load capacities available, plumbing professionals must understand the factors that influence their selection, such as the type of piping used, environmental conditions, and installation techniques. By prioritizing the right pipe hanger clips, contractors can mitigate risks, enhance system longevity, and ultimately deliver reliable plumbing solutions that adhere to industry standards.

When planning plumbing projects, selecting the right type of pipe hanger clips is essential for ensuring both stability and safety. There are several categories of pipe hanger clips, each designed to meet specific needs within different applications. Common options include adjustable pipe hangers, which provide flexibility for varying pipe sizes and positions, and rigid clips that offer robust support for fixed installations. According to the International Association of Plumbing and Mechanical Officials (IAPMO), the chosen hangers should comply with the local building codes, which often specify the necessary load-bearing capacity of the hangers based on the type of pipes being utilized.

In addition to adjustable and rigid clips, there are also specialized options such as insulated pipe clips, which are crucial for preventing condensation and protecting pipes from temperature fluctuations. A report by the Plumbing-Heating-Cooling Contractors National Association (PHCC) highlights that using insulated hangers can reduce energy loss by up to 30% in certain systems, making them a cost-effective choice for long-term plumbing performance. Furthermore, the importance of selecting corrosion-resistant materials cannot be overstated, particularly in environments exposed to moisture and varying chemical exposures, as outlined in studies conducted by the National Association of Corrosion Engineers (NACE). This selection process ensures that the piping system remains durable and operational over time.

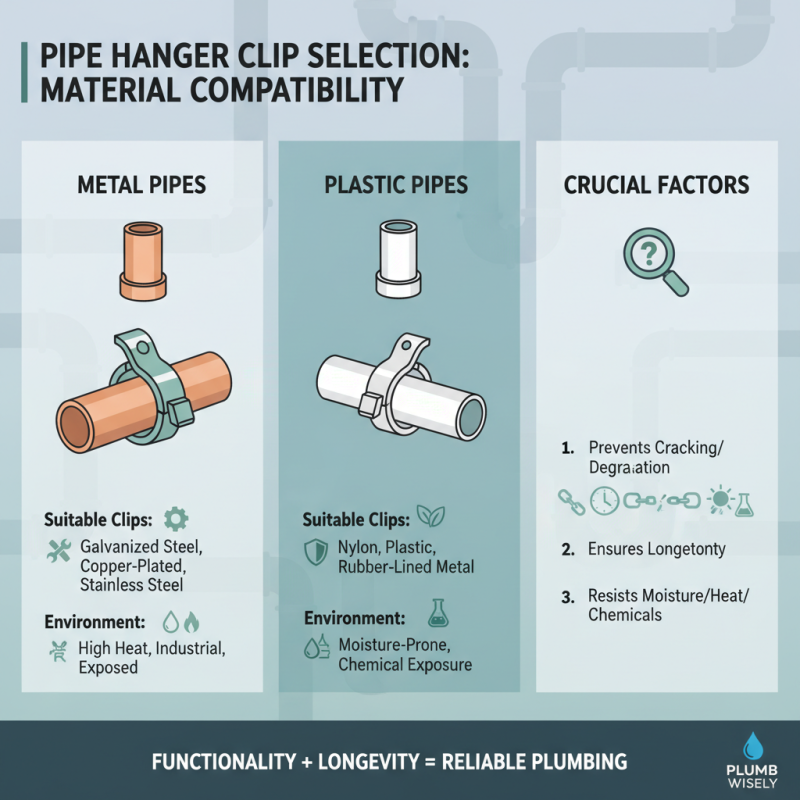

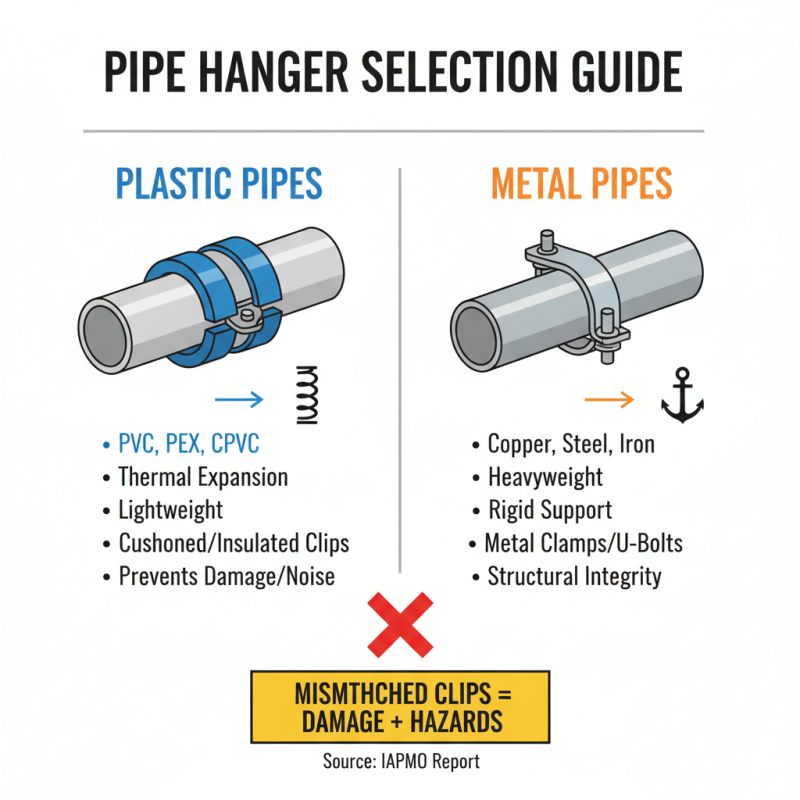

When selecting pipe hanger clips for your plumbing projects, evaluating material compatibility is crucial to ensure both functionality and longevity of your installation. The material of the pipe hanger clip must align with the type of piping it will support. For instance, metal clips are typically suitable for metal pipes but may not be ideal for plastic ones, which could be better served by nylon or plastic clips to prevent cracking or degradation over time. It’s essential to consider factors such as the environment where the pipes are installed; exposure to moisture, heat, or chemicals can influence the performance of the chosen materials.

Additionally, the thermal expansion characteristics of the pipe and the clip material must be assessed. Different materials expand and contract at varying rates, which can lead to misalignment and stress in the piping system if not properly matched. Using clips made from materials that have similar thermal expansion coefficients as the pipes can help mitigate these issues. It is also important to think about the load-bearing requirements of your system, as some materials may not provide adequate support for heavier pipes or could deform under stress. Overall, a careful evaluation of material compatibility not only enhances the effectiveness of the pipe hanger clips but also contributes to the durability and reliability of your plumbing projects.

When selecting pipe hanger clips for plumbing projects, it is essential to assess their load capacity and weight ratings to ensure safety and reliability. According to the American Society of Mechanical Engineers (ASME) standards, the load capacity of pipe hangers largely depends on the materials used and the design specifications. For instance, metal clips typically offer higher load ratings than plastic variants, making them suitable for heavier pipes or applications involving high temperatures.

When evaluating weight ratings, it’s important to consider both the static and dynamic loads. The National Fire Protection Association (NFPA) recommends choosing clips that can handle at least 25% more than the expected load to provide a safety margin. Additionally, consult published data from industry sources like the American National Standards Institute (ANSI) to find specific load capacities for various types of clips based on pipe size and material.

Tips: Always check the manufacturer's specifications for load ratings and installation guidelines to ensure proper usage. Consider environmental factors, such as temperature extremes or corrosive conditions, that may impact the clip's performance over time. Regular maintenance and inspection of installed clips can prevent failures and enhance the longevity of your plumbing system.

When selecting pipe hanger clips for plumbing projects, it's crucial to evaluate the specific installation requirements and considerations. One of the first factors to assess is the type of pipes being used. For example, plastic pipes require different hangers compared to metal ones due to variations in thermal expansion and weight. According to a report by the International Association of Plumbing and Mechanical Officials, using mismatched clips can result in structural damage, leading to costly repairs and safety hazards.

Another critical consideration is the hanging environment. Conditions such as temperature fluctuations, humidity, and exposure to corrosive substances can significantly influence the choice of pipe hanger clips. A recent survey conducted by the Plumbing-Heating-Cooling Contractors Association found that approximately 30% of plumbing failures stem from inadequate support or improper installations, underscoring the need for reliable clips tailored to specific environmental conditions. Properly rated clips not only maintain the integrity of the system but also enhance its longevity by preventing wear and tear over time.

Lastly, local building codes should be a primary concern when choosing pipe hanger clips. Each region may have different regulations regarding the spacing and materials applicable to plumbing installations. It is imperative to reference sources like the National Electrical Manufacturers Association for compliance to avoid potential legal issues and ensure the safety and reliability of plumbing systems. Thus, careful consideration of these elements can lead to better outcomes in plumbing projects, ultimately providing peace of mind for both homeowners and professionals.

When it comes to ensuring the longevity and reliability of plumbing systems, regular maintenance and inspection of pipe hanger clips are essential practices. According to a report by the American Society of Plumbing Engineers (ASPE), improperly maintained pipe support systems can lead to significant structural issues and costly repairs. Professionals recommend conducting inspections at least semi-annually, focusing on signs of corrosion, wear, and alignment issues. By addressing these concerns early, plumbing professionals can prevent more extensive damage and ensure that pipes are adequately supported under varying weights and temperatures.

Furthermore, the National Association of Corrosion Engineers (NACE) highlights that using high-quality materials for pipe hanger clips significantly reduces the risk of corrosion, particularly in environments exposed to moisture. During inspections, it's important to evaluate not only the condition of the clips themselves but also the surrounding environment. Factors such as humidity, temperature fluctuations, and exposure to chemicals should be considered, as they can impact the integrity of the clips. Implementing a proactive maintenance schedule that includes these inspections not only safeguards the infrastructure but also promotes system efficiency, ultimately leading to lower operational costs.