In the complex landscape of mechanical engineering, the choice of a hub coupling is pivotal for ensuring optimal performance and longevity of machinery. According to a report by the International Journal of Mechanical Engineering, nearly 30% of machinery failures can be traced back to inappropriate coupling choices. This emphasizes the importance of selecting the right hub coupling that not only meets the operational demands but also aligns seamlessly with the intended application.

Expert Mark Stevens, a renowned figure in the field of industrial mechanics, highlights, "The effectiveness of a mechanical system is largely dictated by its coupling; an informed choice can prevent significant downtime and maintenance costs." This sentiment resonates amidst the urgency for industries to maintain reliability in high-demand environments. Understanding the variety of hub couplings available, from rigid to flexible designs, allows engineers to tailor their selections based on factors such as torque capacity, misalignment tolerance, and operating conditions.

As we delve into the nuances of choosing the right hub coupling for your mechanical needs, it becomes clear that making an informed decision is not merely a technical requirement, but a strategic advantage in enhancing machinery efficacy and durability.

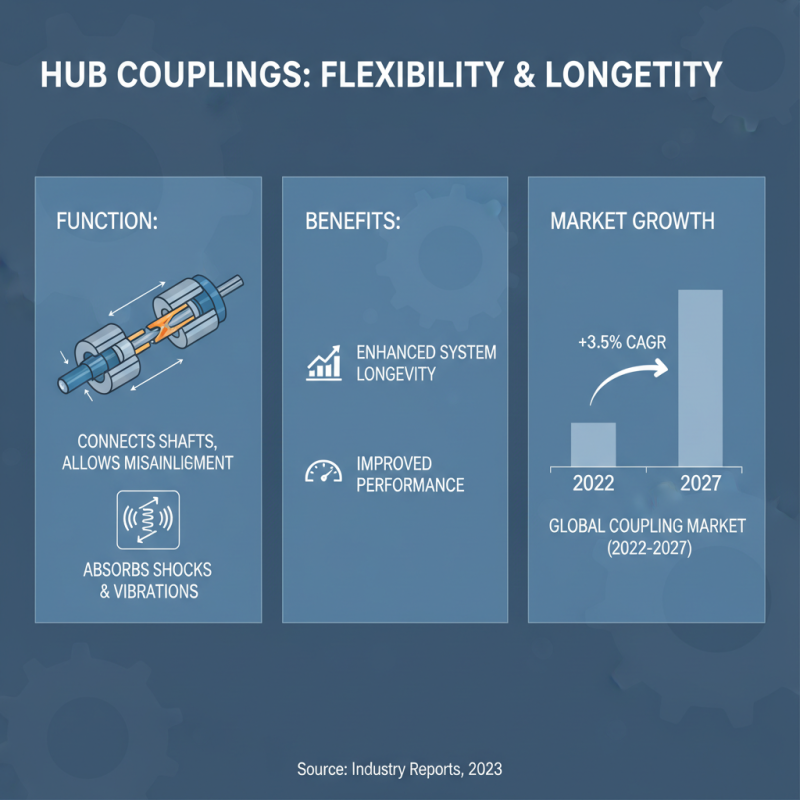

In mechanical systems, hub couplings serve as crucial components that connect two shafts while allowing for misalignment and providing a degree of flexibility. These couplings can absorb shocks and vibrations, which is vital for enhancing the longevity and performance of mechanical systems. Recent industry reports indicate that the global coupling market is projected to grow at a compound annual growth rate (CAGR) of 3.5% from 2022 to 2027, underscoring the increasing importance of selecting the appropriate hub coupling for various applications.

When choosing the right hub coupling, it's essential to consider factors such as torque capacity, misalignment tolerance, and application-specific requirements. A coupling that can accommodate angular, parallel, or axial misalignments will generally perform better, leading to reduced wear and tear on connected components. According to a report by a leading market research firm, approximately 40% of mechanical failures in transmission systems stem from improper coupling selection. Therefore, engineers should conduct a thorough analysis of their mechanical system’s performance needs before making a decision.

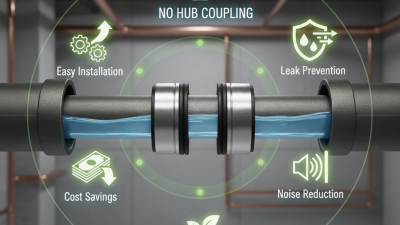

Tips for selecting the right hub coupling include assessing the operating environment, such as temperature and exposure to chemicals, which can affect material integrity. Additionally, consider the ease of installation and maintenance, as well as the coupling's weight, which can impact the overall mechanical balance. Evaluating these factors will help ensure that the coupling chosen not only meets the immediate mechanical needs but also contributes to the overall efficiency and reliability of the system.

When it comes to selecting the right hub coupling for your mechanical needs, understanding your specific mechanical requirements is crucial. Couplings serve as a vital link that transmits power while accommodating misalignment and reducing vibrations. According to a report by ResearchAndMarkets, the global coupling market is projected to grow at a CAGR of 4.6% from 2021 to 2027, highlighting the increasing demand for customized solutions that align with particular operational parameters, such as torque, speed, and environmental conditions.

To identify your specific requirements, begin by assessing the operational characteristics of the machinery involved. Factors such as the maximum torque load, operating speed, temperature ranges, and potential for misalignment significantly impact the type of coupling you should consider. For instance, rigid couplings may be suitable for applications with precise alignment, while flexible couplings can accommodate angular and parallel misalignments more effectively. Furthermore, industry standards, such as those outlined in the ISO 9001 quality management protocol, provide guidelines to ensure that selected couplings can handle the stresses and strains of your specific mechanical applications, ultimately enhancing performance and longevity.

| Coupling Type | Torque Capacity (Nm) | Max RPM | Material | Application |

|---|---|---|---|---|

| Rigid Coupling | 500 | 3000 | Aluminum | General Machinery |

| Flexible Coupling | 300 | 2000 | Steel | Pumps |

| Universal Joint | 600 | 3500 | Chrome Moly | Automotive |

| Oldham Coupling | 200 | 1500 | Plastic | Servo Motors |

| Bellows Coupling | 400 | 2500 | Stainless Steel | Robotics |

When selecting the appropriate hub coupling for your mechanical needs, it's essential to evaluate the various types available on the market. Couplings serve to connect two shafts, allowing for the transmission of power while accommodating misalignment and vibrations. The most common types include rigid, flexible, and fluid couplings, each designed for specific applications and operational conditions.

Flexible hub couplings are particularly advantageous in systems where some degree of misalignment or shock loads may occur. They offer greater versatility, making them suitable for a variety of machinery. Rigid couplings, on the other hand, provide a firm connection, ensuring low backlash and precision, which is ideal for high-speed applications. Additionally, fluid couplings can be beneficial in applications requiring smooth starts and controlled acceleration.

Tips for choosing the right coupling include assessing the operational environment and load conditions. Consider factors such as temperature, speed, and the nature of the loads being transmitted. Additionally, always review the installation space and accessibility, which can influence your selection. Choosing the right hub coupling will enhance the efficiency and longevity of your machinery.

This chart compares various types of hub couplings based on their torque capacity, application suitability, and flexibility. The data represents the average specifications found in the market.

When selecting the right hub coupling for your mechanical needs, several key factors must be taken into account to ensure optimal performance and longevity of your machinery. First, consider the type of load that the coupling will be subjected to. Different applications may experience variable loads, including shock loads, which require a coupling designed to absorb these impacts effectively. Additionally, evaluating the torque requirements of your system is crucial, as the coupling must be capable of handling the necessary torque without slippage or failure.

Another important factor is the compatibility of materials. The environmental conditions where the coupling will be used—such as exposure to moisture, chemicals, or extreme temperatures—can significantly affect its lifespan. Therefore, selecting a coupling made from durable materials that resist wear and corrosion is essential. Furthermore, pay attention to the alignment of your shafts; misalignment can lead to premature wear. Using a flexible coupling may help accommodate slight misalignments, ensuring smooth operation and reducing the need for frequent maintenance. By carefully considering these factors, you can make a more informed decision when choosing a suitable hub coupling for your application.

When it comes to the installation and maintenance of hub couplings, proper attention to detail is crucial for ensuring effective performance and longevity. First, during installation, it’s vital to ensure that the shaft alignment is precise. Misalignment can lead to unnecessary wear and tear, resulting in vibration and potential failure of the coupling. Utilizing alignment tools or laser alignment systems can provide the accuracy needed for a successful setup. Additionally, the coupling should be securely fastened to prevent slippage during operation. Proper tightening of bolts, following the manufacturer’s specifications, will help maintain optimal functioning.

Maintenance plays an equally important role in the lifecycle of hub couplings. Regular inspections should include checking for signs of wear, such as cracks or deformation of the coupling material. Lubrication, if applicable, should also be conducted at the recommended intervals to reduce friction and wear on the components. It's essential to monitor operational temperature and vibration levels to detect issues early. Implementing a routine maintenance schedule can ensure that any potential problems are addressed promptly, ultimately extending the lifespan of the coupling and enhancing overall system reliability.