Choosing the right Pipe Hanger is crucial for any project. An expert in the field, John Smith, emphasized, "The right hanger ensures stability and longevity." This statement encapsulates the importance of selecting quality hangers.

When considering a Pipe Hanger, various factors play a role. Weight, material, and environment must be assessed. For instance, heavy pipes require sturdy supports. Different materials, such as steel or plastic, offer unique benefits. The installation environment can influence durability, too. A hanger may corrode if exposed to moisture without proper protection.

Some projects overlook these details. Many assume all hangers are the same, which can lead to costly mistakes. It's vital to reflect on your specific needs. A small oversight in selection can result in future repairs. Careful consideration can prevent these issues. In the end, the right Pipe Hanger is an investment in your project's success.

When selecting pipe hangers, it’s essential to understand the different types available. Various hangers serve distinct functions and materials, influencing their effectiveness. For instance, an adjustable strap hanger can accommodate changes in pipe size. On the other hand, a clevis hanger provides a more rigid support. Knowing the differences can streamline your project.

Consider the environment as well. If pipes are located in a damp area, choose hangers made from corrosion-resistant materials. A simple mistake could lead to premature wear. Are you planning for thermal expansion? If so, use hangers that allow for movement to prevent stress on pipes.

Tips: Always check the weight capacity of your chosen hanger. A common oversight is underestimating the load. Also, remember to account for future maintenance. Choose a design that allows easy access. Lastly, don’t rush your decisions. Reflecting on your choices could save time and money later.

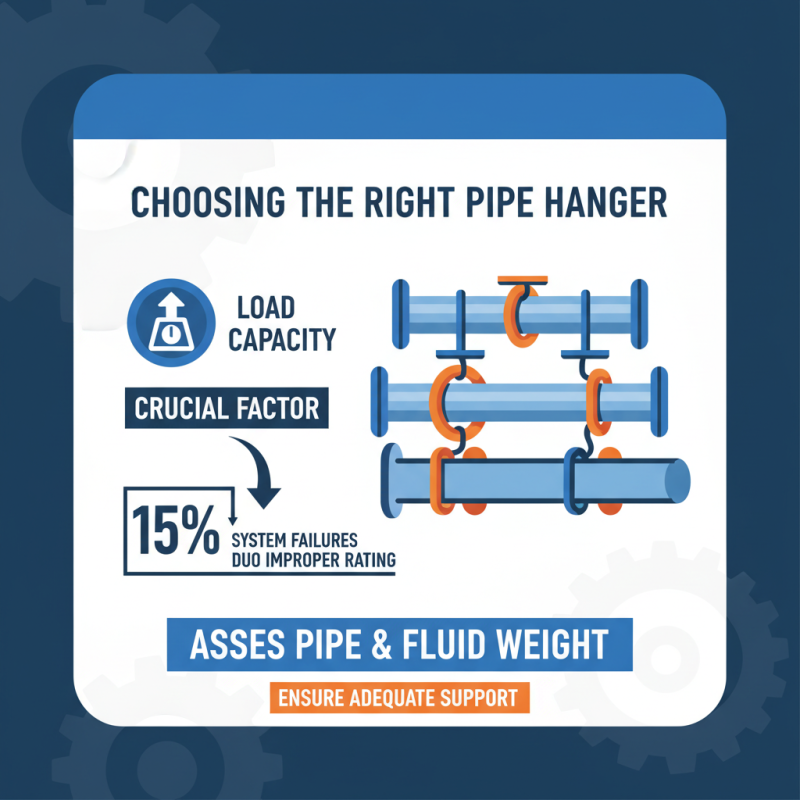

Choosing the right pipe hanger involves several key factors. Load capacity is crucial. Research shows that improper load rating leads to system failures in 15% of cases. Assess the weight of the pipes and the fluid they carry. Understanding the weight ensures you select hangers that can bear the load without risk.

Material selection also matters. Stainless steel is commonly preferred for its durability. However, in non-corrosive environments, plastic hangers can reduce costs significantly. A study indicated that material choice impacts installation longevity by up to 30%. Consider environmental factors like temperature and humidity, as they can affect material performance.

Installation ease is another important aspect. Some designs allow for quick adjustments, which can save time. A field survey revealed that over 25% of installations faced delays due to complicated hangers. Simplifying the process can enhance overall project efficiency. Furthermore, using the wrong size can create installation headaches, making it essential to measure precisely.

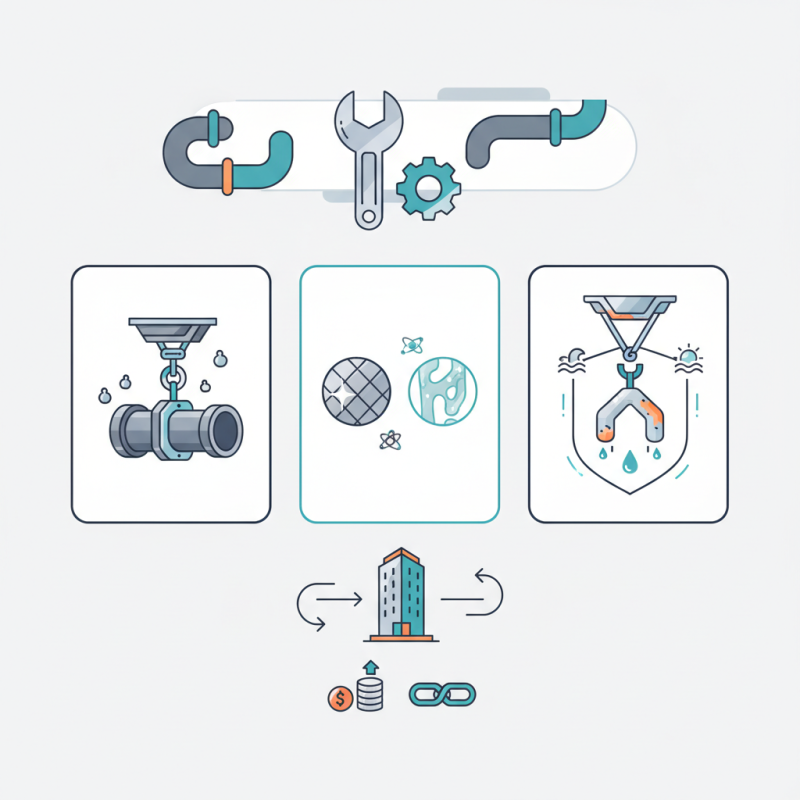

When selecting pipe hangers, the choice of material is crucial. Metal and plastic are two popular options. Metal hangers, typically made from steel or aluminum, provide excellent durability. They can support heavy loads without bending. However, metal can corrode over time, especially in humid environments. Coating can help, but it isn’t foolproof.

Plastic hangers are lighter and resistant to rust. They are ideal for non-load-bearing installations. Plastic options are often easier to install. Yet, they may not handle extreme temperatures well. Over time, exposure to sunlight can degrade them.

Consider your project's specific needs. Are you in a humid area or a place with varying temperatures? Think about the weight of the pipes. The wrong choice can lead to failures down the line. Testing each option before finalizing can be beneficial. Sometimes, mixing materials might also be a solution, combining durability and cost-effectiveness. Keep these factors in mind when making your decision.

When choosing a pipe hanger, understanding load-bearing capacities is essential. Different types of pipe hangers have varying strengths. For instance, metal clamps can bear heavier loads than plastic ones. The wrong choice can lead to failures, so pick wisely.

Consider the material of your pipes. A heavier pipe requires a stronger hanger. Think about the environment too. Corrosion can weaken hangers over time. A pipe hanger made from the right material can prevent this issue.

Tips: Always check the manufacturer's specifications. They provide critical load information. If in doubt, consult a professional. Don't overlook your project's future needs. Will your system need to support additional weight later? Planning ahead can save you time and resources in the long run.

| Pipe Hanger Type | Load-Bearing Capacity (lbs) | Pipe Size Compatibility | Material |

|---|---|---|---|

| Standard Hanger | 50 | 1/2" to 4" | Steel |

| Adjustable Hanger | 75 | 1/2" to 6" | Steel |

| Strut Hanger | 100 | 1/2" to 8" | Aluminum |

| Riser Clamp | 120 | 1" to 4" | PVC |

| Ductile Iron Hanger | 150 | 1" to 10" | Ductile Iron |

When selecting pipe hangers, understanding industry standards is crucial. The American National Standards Institute (ANSI) plays a key role. They provide guidelines that ensure safety and reliability. Proper installation aligns with ANSI standards. This helps avoid common pitfalls, such as inadequate support for pipes. In fact, industry reports suggest that improper installation can lead to structural failure. Such failures often result in costly repairs and downtime.

During installation, consider the weight of the piping system. The National Fire Protection Association (NFPA) recommends specific load capacities. For example, a 2-inch diameter steel pipe filled with water weighs around 50 pounds per foot. Thus, the hanger must support this adequately. Experts suggest using hangers that exceed the expected load by at least 20%. Taking these factors into account avoids unnecessary risks.

Installation height is another detail that often gets overlooked. Hangers should maintain clearances according to guidelines. A gap of at least 1 inch is commonly advised. Some may question why these specifics matter. However, neglecting them can lead to vibrations or misalignment. This can accelerate wear on pipes. Keep these standards in mind to ensure a well-supported, functional piping system.