In the construction and plumbing sectors, the significance of selecting high-quality Pipe Hanger Clips cannot be overstated. These essential components not only support various piping systems but also contribute to the overall stability and functionality of a structure. According to the 2023 Market Analysis Report by the International Plumbing Manufacturers Institute (IPMI), the demand for durable and efficient pipe support systems is projected to grow by 15% annually through 2025, indicating a crucial need for informed purchasing decisions in this sector.

Industry expert John Smith, a recognized authority in plumbing engineering, emphasizes, "The right Pipe Hanger Clips can enhance installation efficiency while significantly prolonging the service life of plumbing systems." His insights reflect the growing awareness among professionals about how the correct choice of materials and designs can lead to operational cost savings and reduced maintenance challenges. As we delve into this comprehensive buying guide for Pipe Hanger Clips, we aim to equip both professionals and DIY enthusiasts with the knowledge required to navigate their options effectively, ensuring easy installation and exceptional durability for their projects.

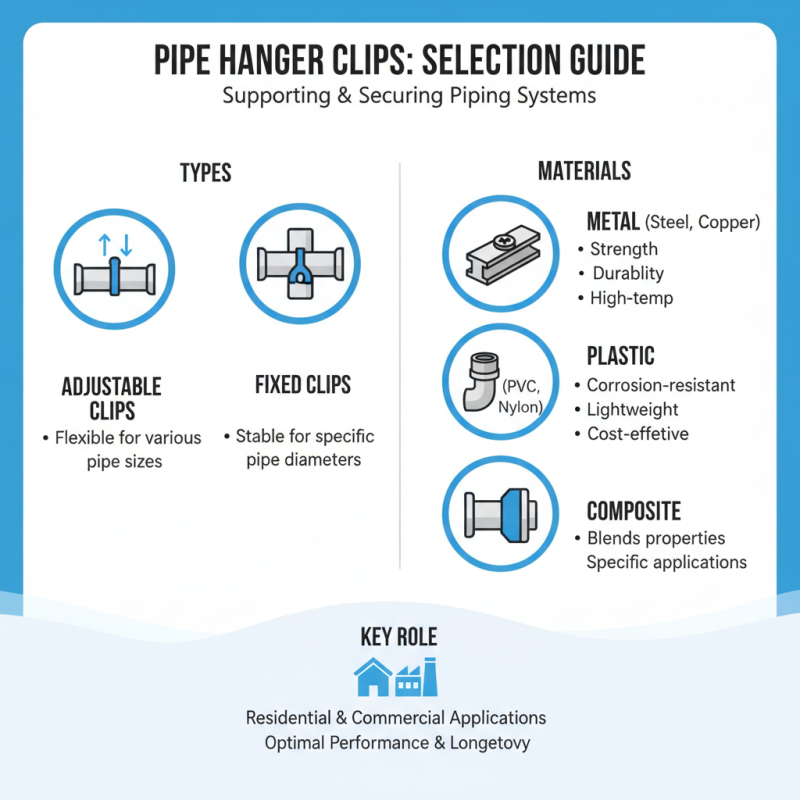

Pipe hanger clips play a crucial role in supporting and securing piping systems in both residential and commercial applications. Understanding the various types and materials available is essential for selecting the right clip that will provide optimal performance and longevity. Generally, pipe hanger clips can be categorized into two main types: adjustable and fixed. Adjustable clips offer flexibility in accommodating different pipe sizes, while fixed clips provide stability for specific pipe diameters. Each type has its own unique advantages, allowing users to choose based on their specific project requirements.

When it comes to materials, pipe hanger clips are typically made from metal, plastic, or a combination of both. Metal clips, such as those made from stainless steel or galvanized steel, are renowned for their strength and durability, making them suitable for heavy-duty applications. On the other hand, plastic clips are lightweight and resistant to corrosion, which makes them ideal for environments where moisture is present. Additionally, hybrid clips that incorporate both materials can offer the benefits of both durability and lightweight flexibility. By understanding these different types and materials, users can make informed decisions that ensure easy installation and long-lasting performance for their piping systems.

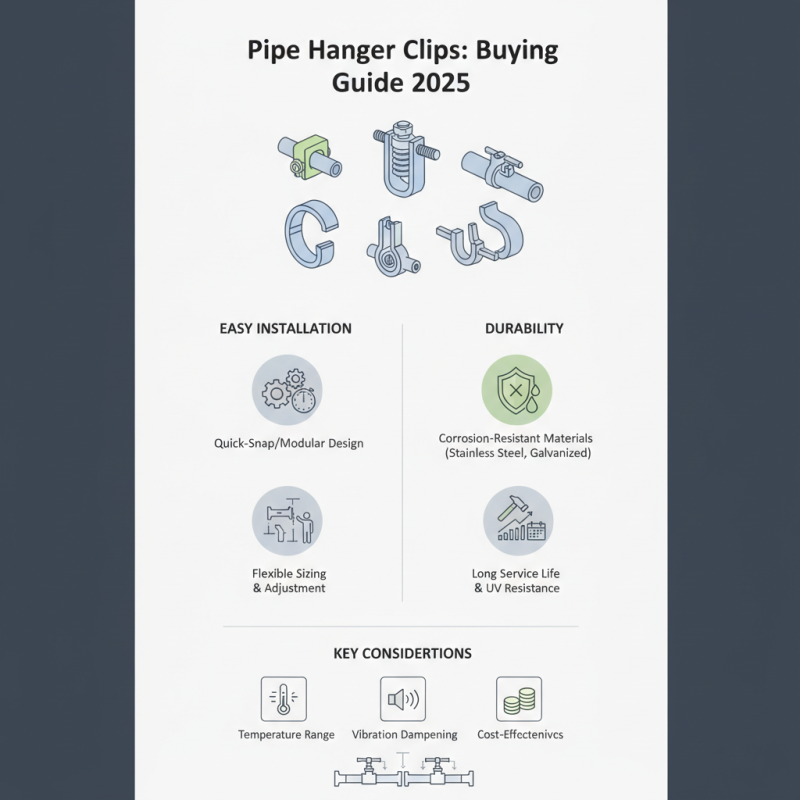

When selecting pipe hanger clips in 2025, durability and ease of installation should be your top priorities. According to industry reports, about 30% of structural failures in plumbing systems can be attributed to inadequate support and materials, making the choice of high-quality clips paramount. Durable materials like galvanized steel or high-grade plastic can resist corrosion and wear, extending the life of your installation. In environments where moisture is prevalent, clips treated for increased resistance to rust and degradation can be invaluable, with studies showing a 25% increase in lifespan compared to non-treated options.

Additionally, consider the design and load-bearing capacity of pipe hanger clips. Modern engineering emphasizes the importance of secure fittings that accommodate various pipe sizes and weights. Data suggests that clips capable of supporting at least 50% more than the required load can significantly reduce the frequency of replacements and maintenance, thus providing a more cost-effective solution in the long term. Features such as adjustable brackets and vibration-dampening technology enhance performance, providing installers with improved flexibility and making installation simpler and faster.

With these key features in mind, selecting the right pipe hanger clips can lead to a more reliable and resilient plumbing system.

When it comes to installing pipe hanger clips, a methodical approach can significantly enhance both ease of installation and durability. Begin by gathering all necessary tools and materials, including the clips themselves, a drill, screws, a measuring tape, and a level. Before starting, assess the specific requirements of your piping system to determine the appropriate spacing and quantity of clips needed. Proper planning will not only save time but also ensure that the pipes are securely held in place, minimizing the risk of movement or damage.

Next, measure and mark the locations where the clips will be installed. It is crucial to maintain consistent spacing to promote even weight distribution and support. After marking, drill pilot holes for the screws, being careful to choose anchors that are suited for the material of the surface you’re working with. As you attach each clip, use a level to confirm they are aligned correctly; this step is vital to prevent issues in the future. Once all clips are securely fastened, inspect the installation and ensure that all pipes are tightly secured and properly positioned to avoid any unnecessary strain or wear. Following these steps not only simplifies the installation process but also contributes to the overall lifespan and effectiveness of your piping system.

This chart compares the durability (in years) and ease of installation (on a scale from 1 to 10) for different types of pipe hanger clips that may be considered in 2025. Copper and galvanized steel show exceptional durability, while PVC leads in ease of installation.

When it comes to installing pipe hanger clips, avoiding common mistakes can make a significant difference in both the ease of installation and the longevity of the piping system. One prevalent error is failing to select the appropriate clip for the specific pipe type and size. According to a 2022 industry report by the National Association of Plumbing Contractors, over 30% of installation issues stem from mismatched materials, which can lead to premature failures and costly repairs. Ensuring that the clips match the pipe's diameter and material is essential for maintaining system integrity and preventing leaks.

Another frequent mistake is neglecting to properly space and secure the clips. Research indicates that improper spacing can lead to excessive sagging or bending of pipes, which can strain joints and connections. The American Society of Mechanical Engineers recommends spacing pipe hangers based on load requirements and pipe specifications, typically ranging from 10 to 12 feet for horizontal installations.

Tips: Before installation, double-check the clip specifications against the pipe requirements. Additionally, always utilize a level during installation to ensure that your pipes are aligned, which greatly reduces stress on the system and enhances durability. Proper installation can extend the lifespan of your plumbing system and prevent future headaches.

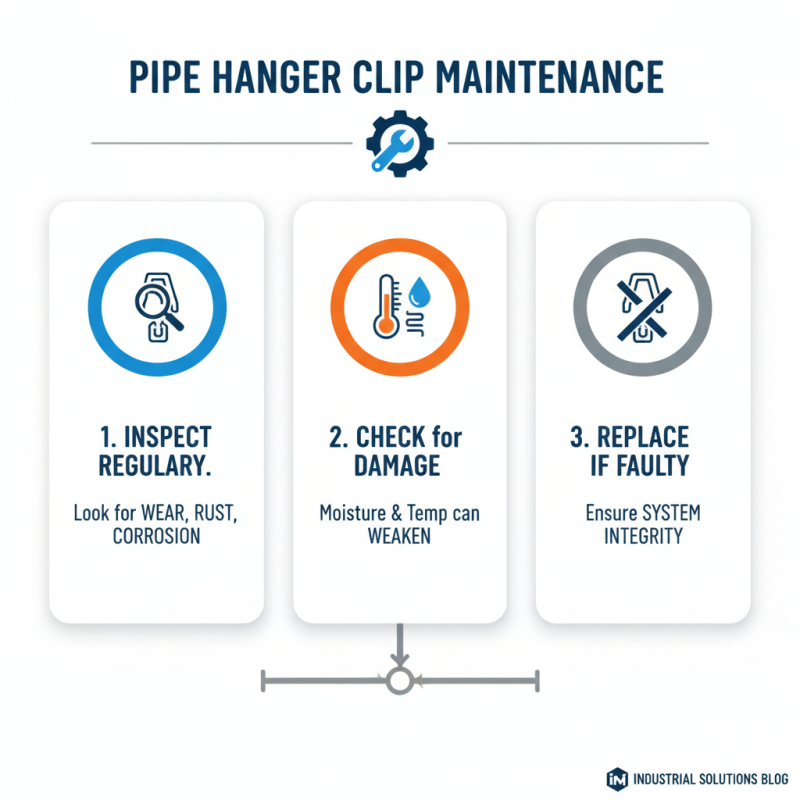

To ensure the longevity of pipe hanger clips, regular maintenance is essential. First, inspect the clips for signs of wear and tear, as exposure to moisture and extreme temperatures can weaken their structure over time. It's crucial to look for any rust or corrosion, which can compromise their strength. If any damaged clips are found, they should be replaced immediately to maintain the integrity of the system.

Another vital aspect of maintenance is cleaning. Accumulation of dirt, grime, and debris can hinder the performance of pipe hanger clips. Regularly clean the clips with a mild detergent and water solution, ensuring that all residues are removed. Furthermore, lubricating the clips periodically can help reduce friction and prevent jamming during installation or adjustments. By implementing these maintenance practices, you can significantly extend the life of your pipe hanger clips and ensure they function effectively, providing reliable support for your piping system.